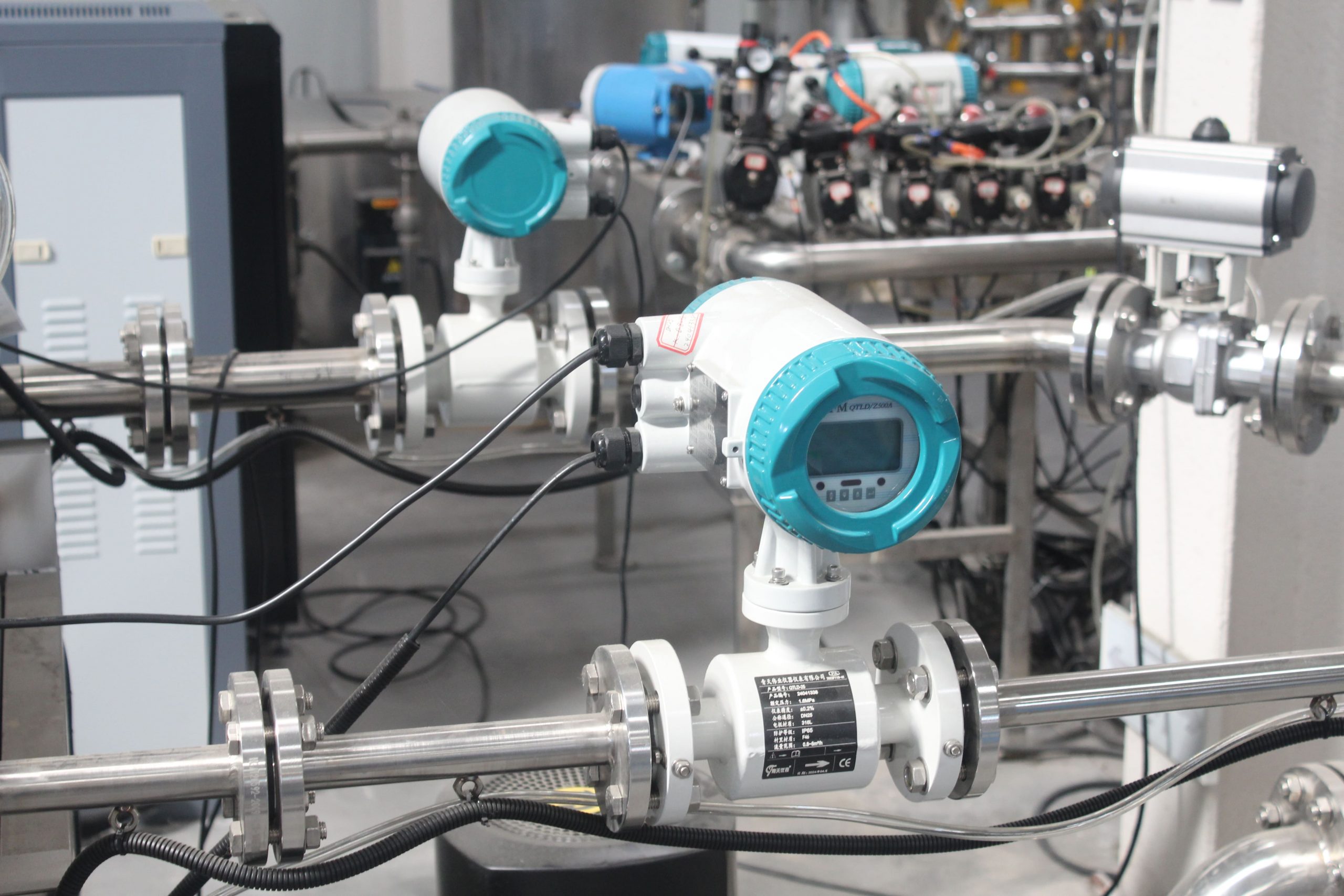

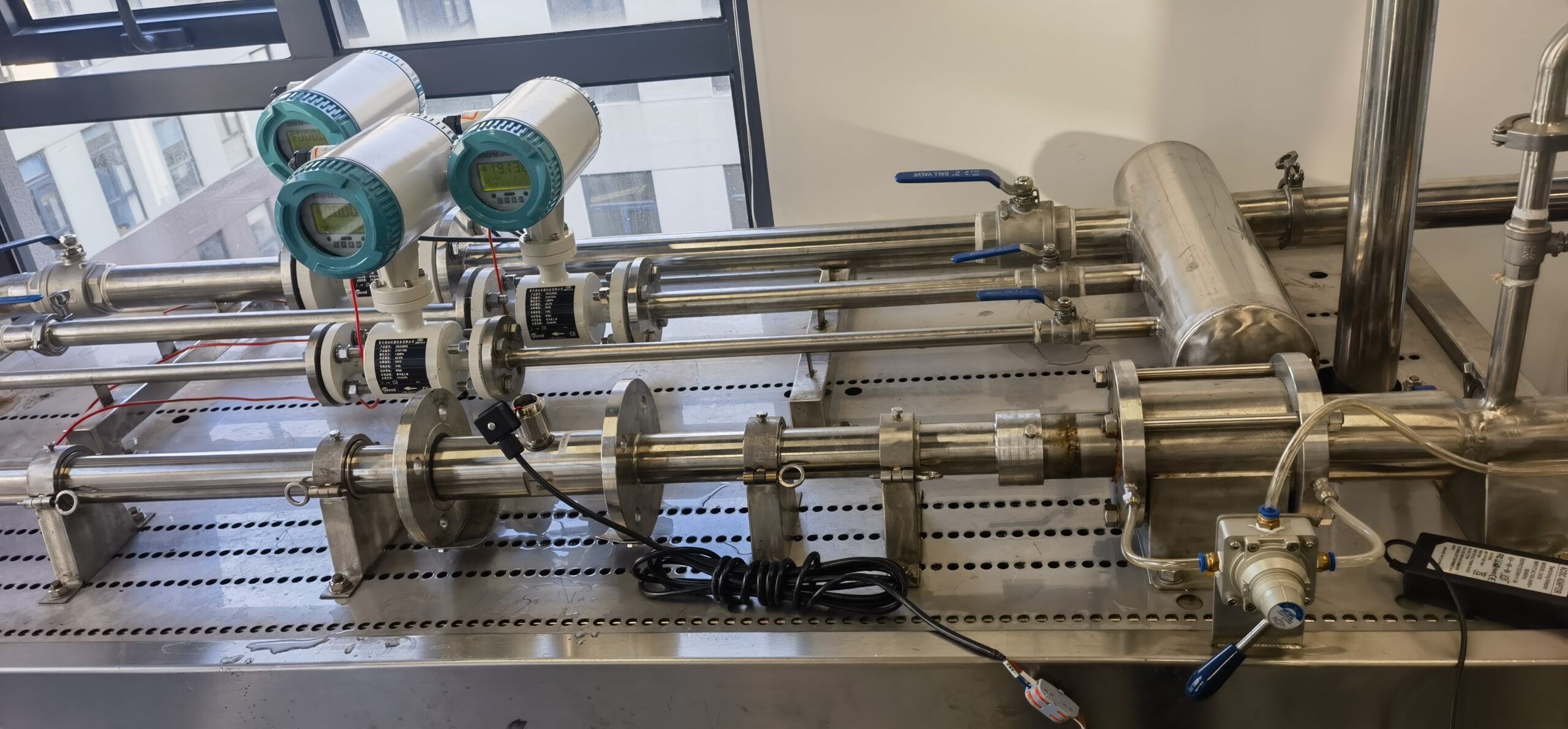

Electromagnetic flow meter in the water supply points

The scale of the water supply system itself is huge, and the environment in which it is located is complex and changeable, requiring the electromagnetic flowmeter to have strong stability and reliability, so in the actual use process, the matters needing attention should be clear.

1. The electromagnetic flowmeter itself has higher requirements for the straight pipe, and some old water supply systems do not have the installation conditions, even if it is forcibly installed, it cannot guarantee the stability and reliability of the measurement. In this regard, if conditions permit, the flow characteristics of the fluid can be improved by setting the rectifier tube at the appropriate position to ensure the correctness of the measurement results.

2. If the velocity of the measured water flow is too low, the measurement accuracy will also be affected, especially at the end of the water supply system pipe network. Therefore, when using electromagnetic flow timing, the valves on both sides of the boundary should be kept open as far as possible.

3. The sensor surface must be clean and tidy to avoid contamination with sludge. In the selection and use of electrodes, you can use a scraper electrode or an electrode with an ultrasonic cleaning module, develop a practical maintenance plan to reduce interference factors as much as possible, ensure the stability of the electrode, and ensure that it can be used normally.

4. The inlet pipe of the electromagnetic flowmeter needs to be kept smooth, and there can be no accumulation, because the accumulation will directly affect the flow characteristics, causing the problem of excessive error in the result. The management department of the water supply system should arrange personnel to clean the pipes regularly.

5. The electromagnetic flowmeter is usually set in a relatively open area, which is easily damaged by lightning strikes during thunderstorms, and the entire module may be broken down in serious cases. From the perspective of ensuring safety and reducing losses, when the electromagnetic flowmeter is installed and used, it is necessary to set corresponding lightning protection measures, such as installing lightning rods and setting lightning protection ground nets.

6.The normal operation of the electromagnetic flowmeter needs to have a power supply as support, if it is installed outdoors, the connection of the power supply is a big problem, and the occurrence of power failure, the electromagnetic flowmeter will appear data loss, after the power failure, the measurement of water will become very cumbersome, but also need to communicate with the user. In order to solve this problem, in addition to setting multiple power supplies, increasing power protection and other measures, technicians should also strengthen the improvement of the electromagnetic flow meter, through the way of own power supply to solve the above problems.

7. The accuracy level of the electromagnetic flowmeter should be determined according to the specific measurement requirements to reduce the cost of use. For example, if it is used for trade settlement, accuracy levels such as 0.3 and 0.5 should be selected, and if it is used for process control, lower accuracy levels such as 1.0 can be selected.

8. When measuring the general medium, the full degree measurement of the electromagnetic flowmeter can be selected in the range of the medium flow rate of 0.3-12m/s, and the range of options is larger. The specifications of the instrument do not necessarily have to be the same as the diameter of the pipe, and it should be seen whether the measured flow range is within the flow rate range. If the flow rate of the pipeline is low, it can not meet the working requirements of the electromagnetic flowmeter, the accuracy of the measurement results will be affected, and it is necessary to appropriately reduce the diameter of the instrument and improve the flow rate of the pipeline.