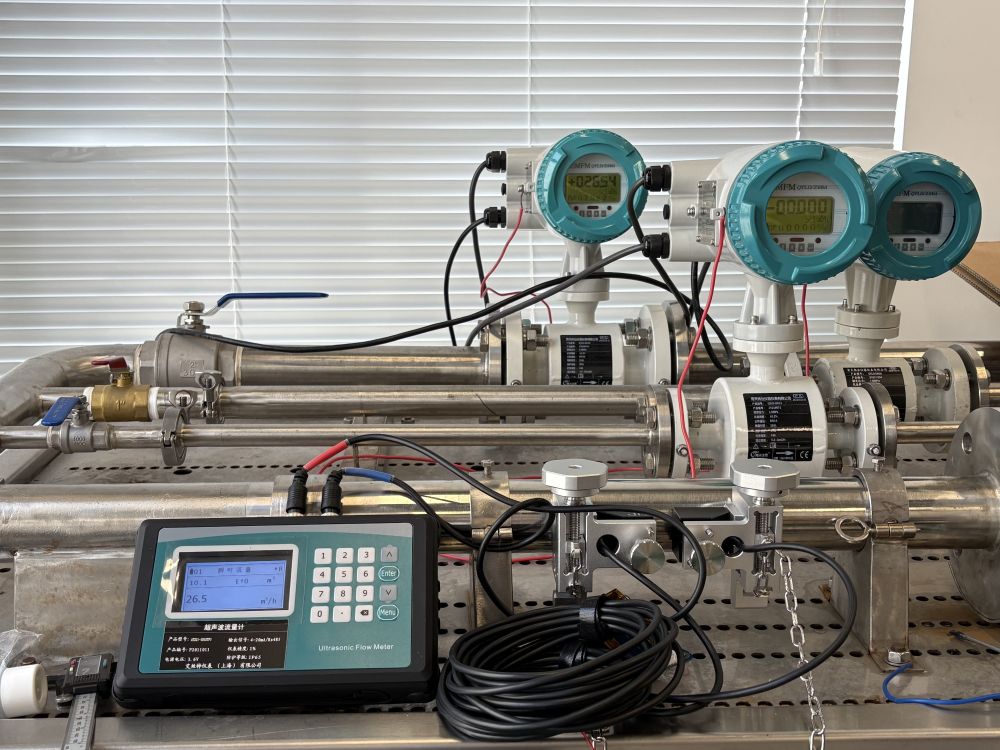

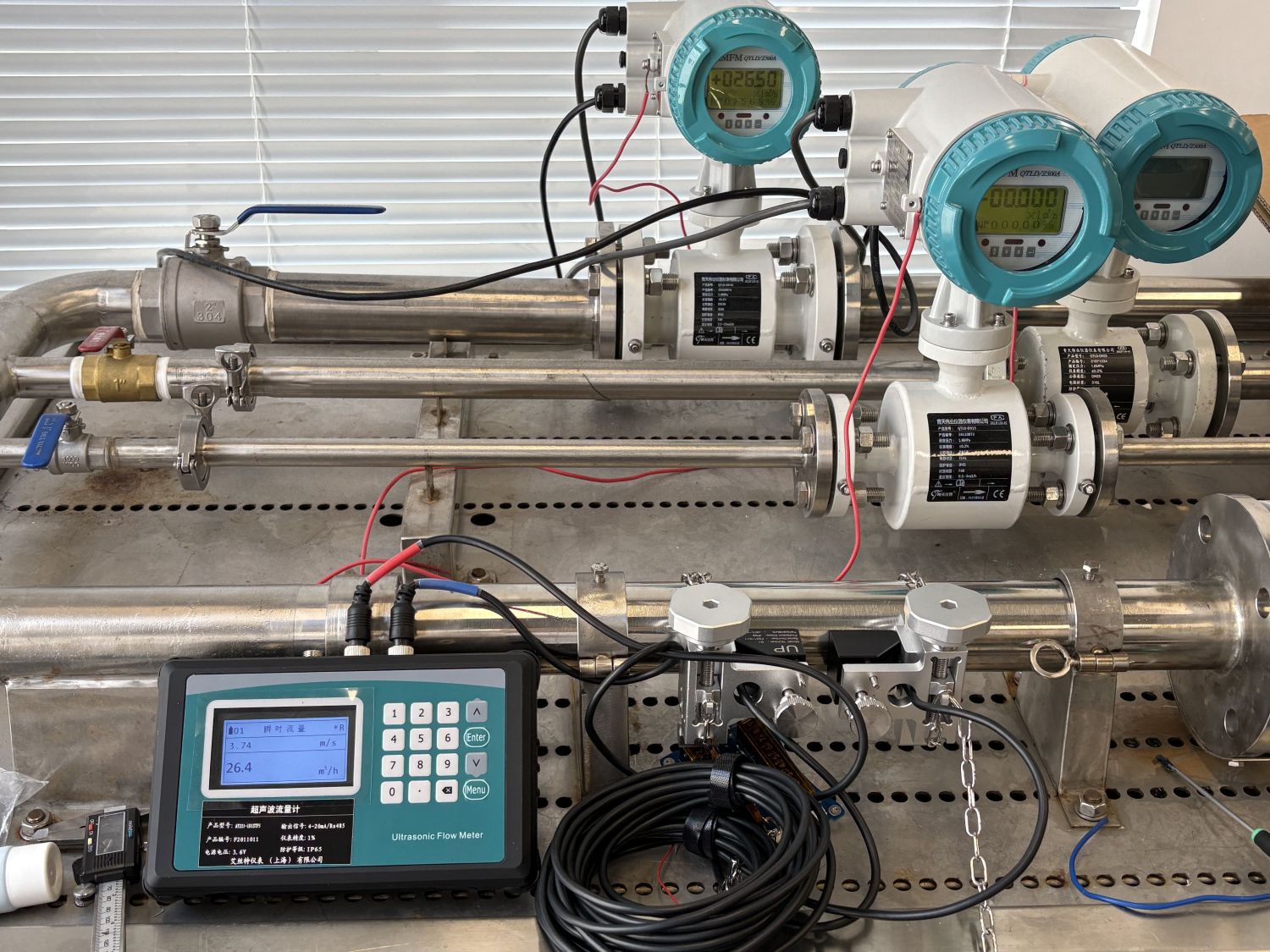

Digital RS485 Data Logger New Technology BTU Ultrasonic Heat Flowmeter

Ultrasonic flowmeters are well-suited for measuring the flow of clean liquids in a variety of industrial applications. Clean liquids, such as water, chemicals, or other non-viscous fluids, allow ultrasonic signals to propagate through the medium more effectively, resulting in accurate flow measurements. Here are some considerations for using ultrasonic flowmeters with clean liquids:

Signal Propagation:

Ultrasonic flowmeters rely on the transmission of ultrasonic signals through the liquid. Clean liquids with minimal impurities or bubbles allow for better signal propagation.

Transducer Performance:

Transducers are key components of ultrasonic flowmeters. Clean liquids help maintain the performance of transducers by preventing deposits or contamination on their surfaces.

No Obstructions in the Flow Path:

Clean liquids ensure that there are no obstructions, such as particles or debris, in the flow path. Obstructions can interfere with the ultrasonic signals and lead to inaccurate measurements.

High Accuracy:

Ultrasonic flowmeters can provide high accuracy in measuring clean liquids. Proper installation and calibration contribute to the reliability and precision of the measurements.

Minimal Maintenance:

Using ultrasonic flowmeters with clean liquids reduces the need for frequent maintenance. Regular cleaning of transducer surfaces may be required, but the overall maintenance is typically less compared to applications with dirty or abrasive fluids.

Wide Range of Applications:

Ultrasonic flowmeters are versatile and suitable for various industries, including water and wastewater management, chemical processing, pharmaceuticals, and more, where clean liquids are commonly encountered.

It’s important to note that while ultrasonic flowmeters work well with clean liquids, certain factors may affect their performance. For example, extreme temperatures, high viscosity, or the presence of gases in the liquid may require specific considerations or additional features in the ultrasonic flowmeter design.