Correctly understand the value of electromagnetic flow meter in industrial measurement

The measuring channel of the electromagnetic flowmeter is a smooth straight pipe of an unimpeded flow detector, which is not easy to block and is suitable for measuring liquid-solid two-phase fluids containing solid particles or fibers, such as paper pulp, coal water pulp, mineral pulp, mud and sewage.

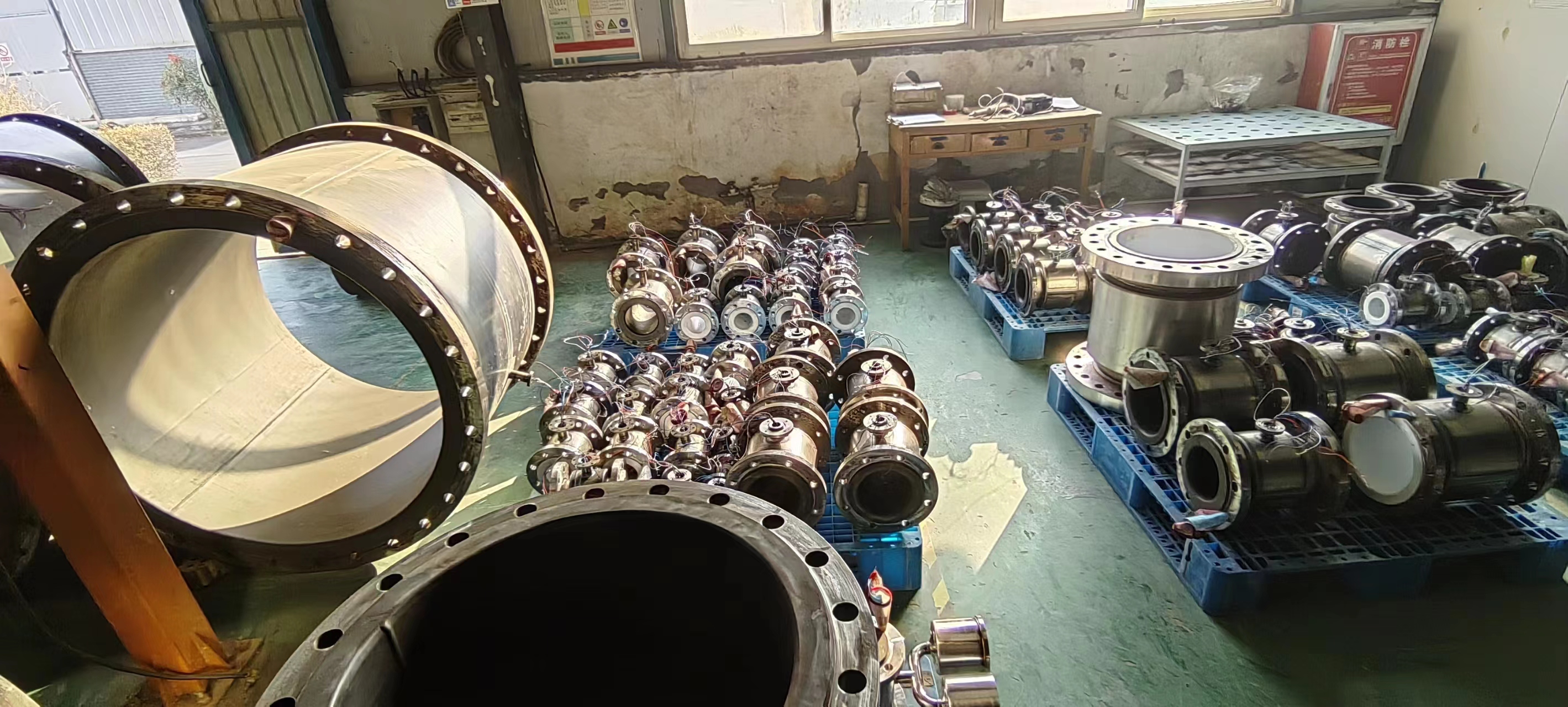

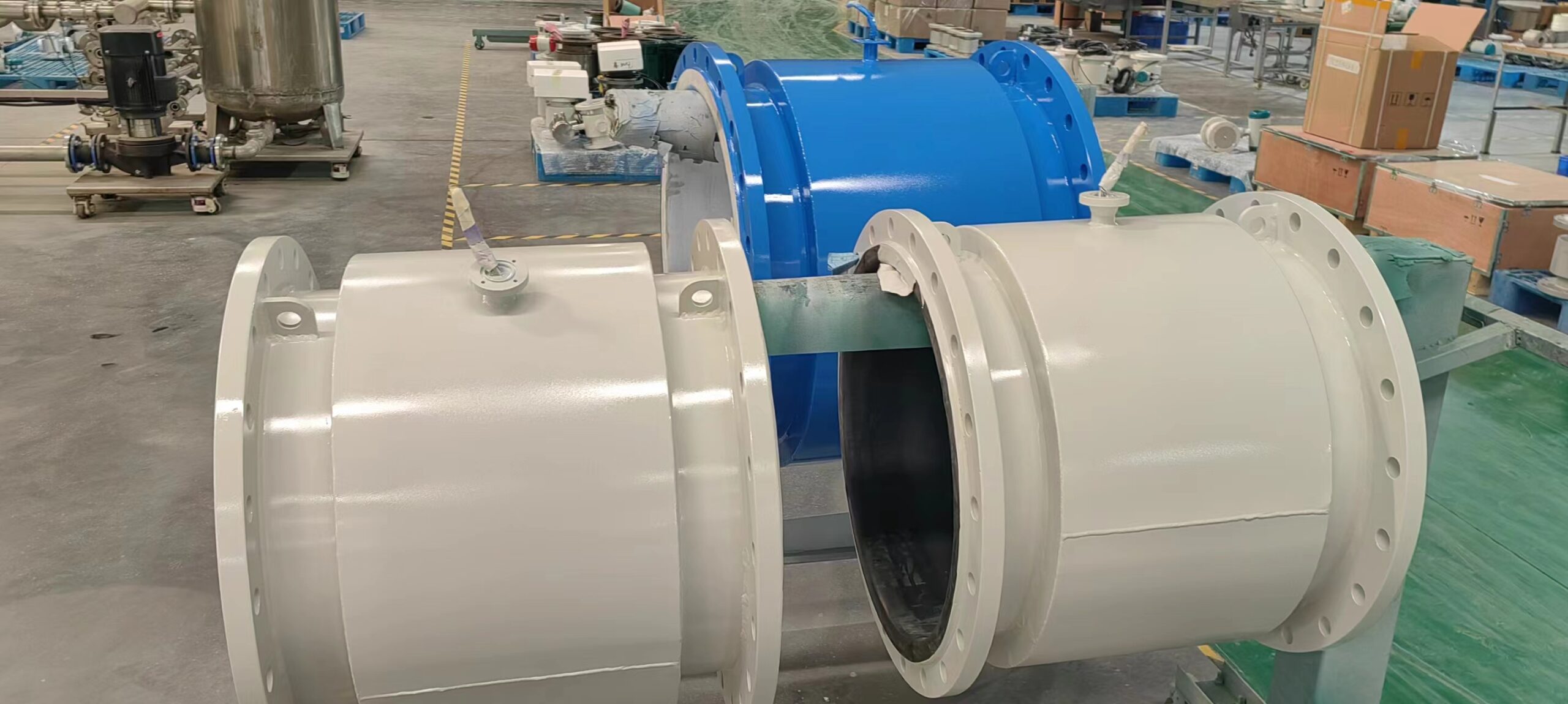

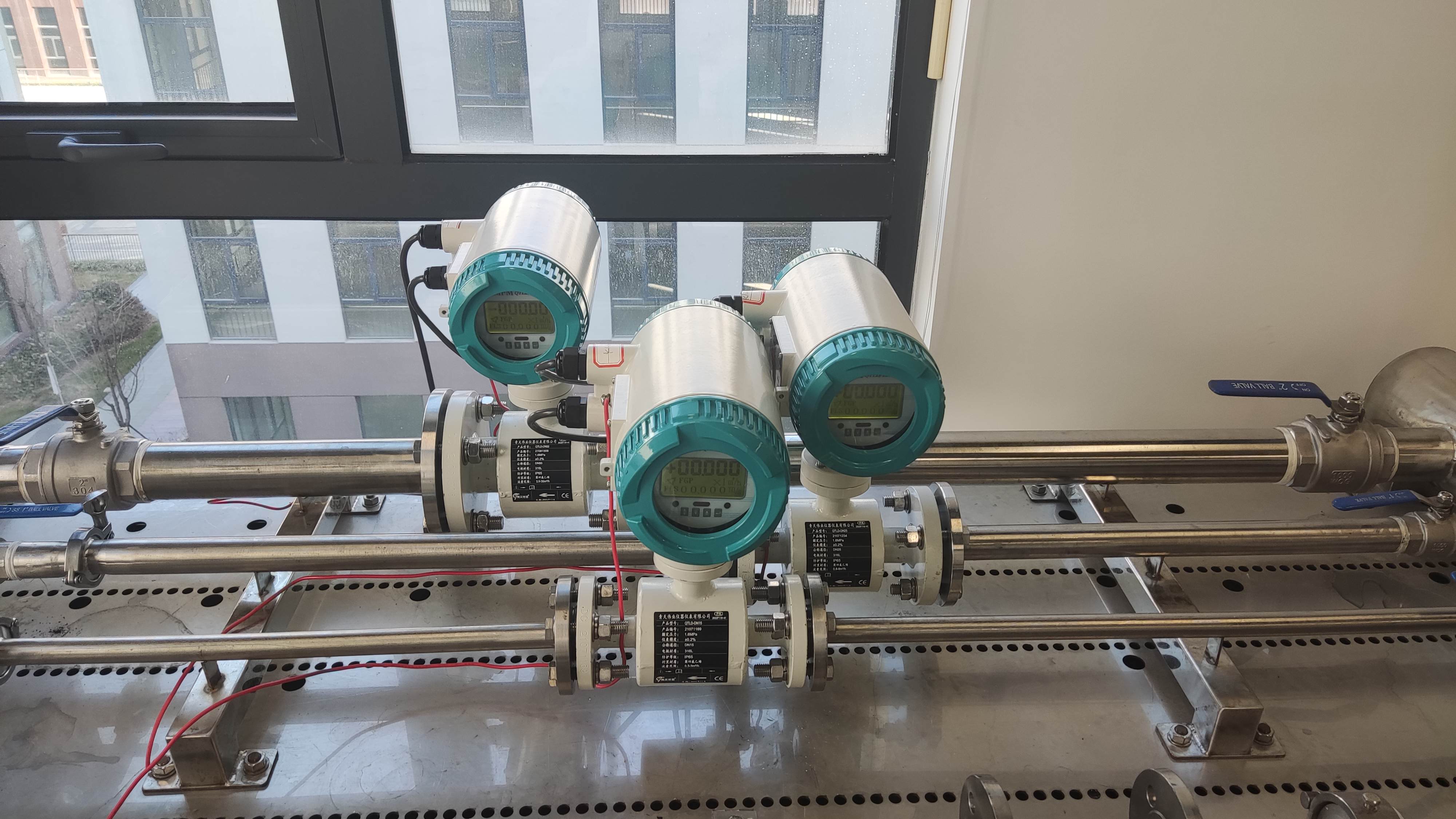

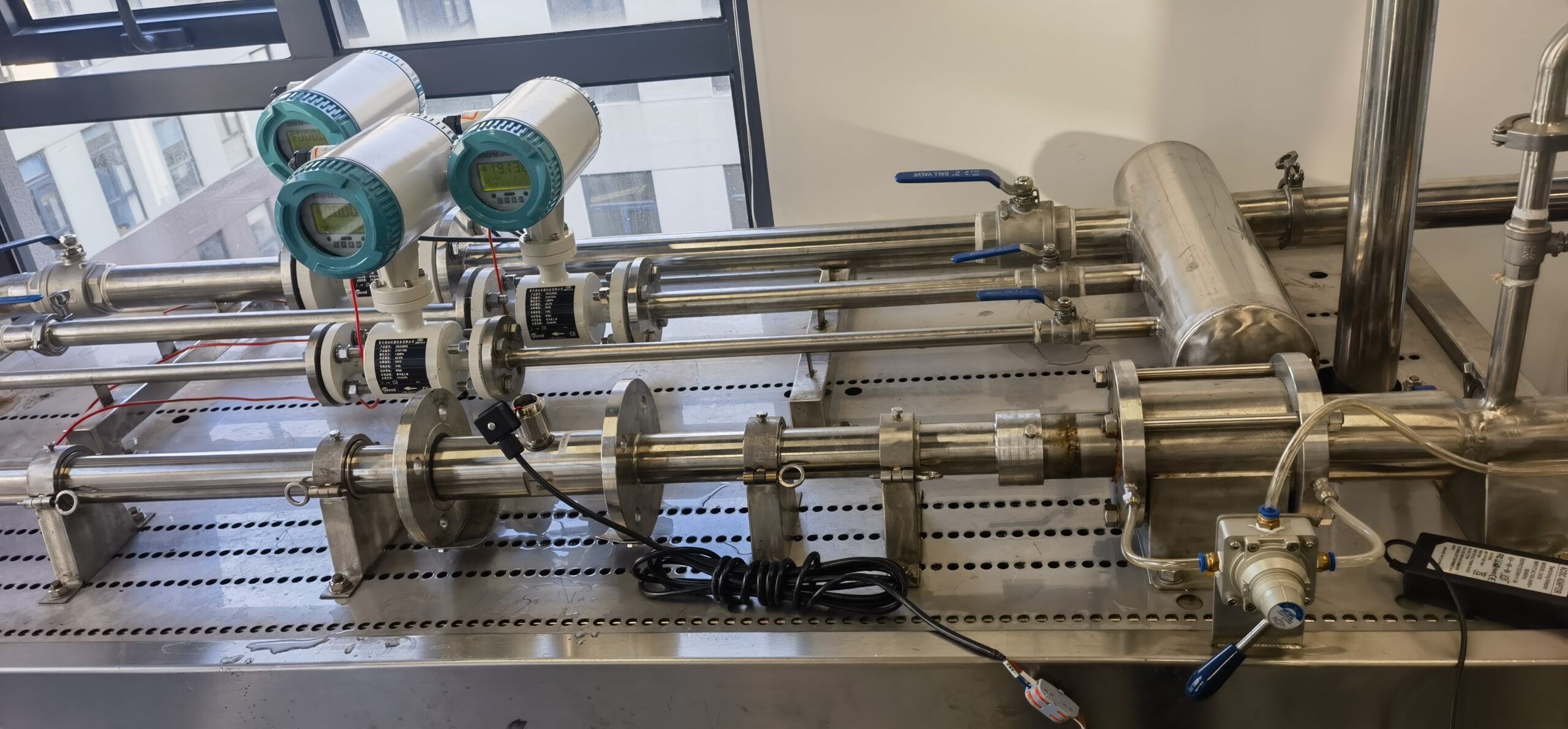

The measuring channel of the electromagnetic flowmeter is a smooth straight pipe of an unimpeded flow detector, which is not easy to block and is suitable for measuring liquid-solid two-phase fluids containing solid particles or fibers, such as paper pulp, coal water pulp, mineral pulp, mud and sewage. The electromagnetic flowmeter does not produce pressure loss caused by the detection flow, and the resistance of the meter is only the resistance along the same length pipeline, which has significant energy saving effect, and is more suitable for large pipe water supply pipelines requiring low resistance loss. The measured volume flow rate is virtually unaffected by changes in fluid density, viscosity, temperature, pressure, and conductivity (as long as it is above a certain threshold). The front straight section has lower requirements than most other flow meters. The measuring range of the electromagnetic flowmeter is large, usually 20:1 ~ 50:1, and the optional flow range is wide. The liquid flow rate can be selected within 0.5 ~ 10m/s. Some models of meters can expand and reduce the flow rate as needed in the field (for example, with a 4-digit potentiometer to set the meter constant) without having to be removed for offline real current calibration. The EMF has a wider aperture range than other varieties of flow meters, from a few millimeters to 3m. Can measure the positive and negative two-way flow, can also measure the pulsation flow, as long as the pulsation frequency is much lower than the excitation frequency. The output of the instrument is linear in nature. Easy selection of materials in contact with fluids for use in corrosive fluids.

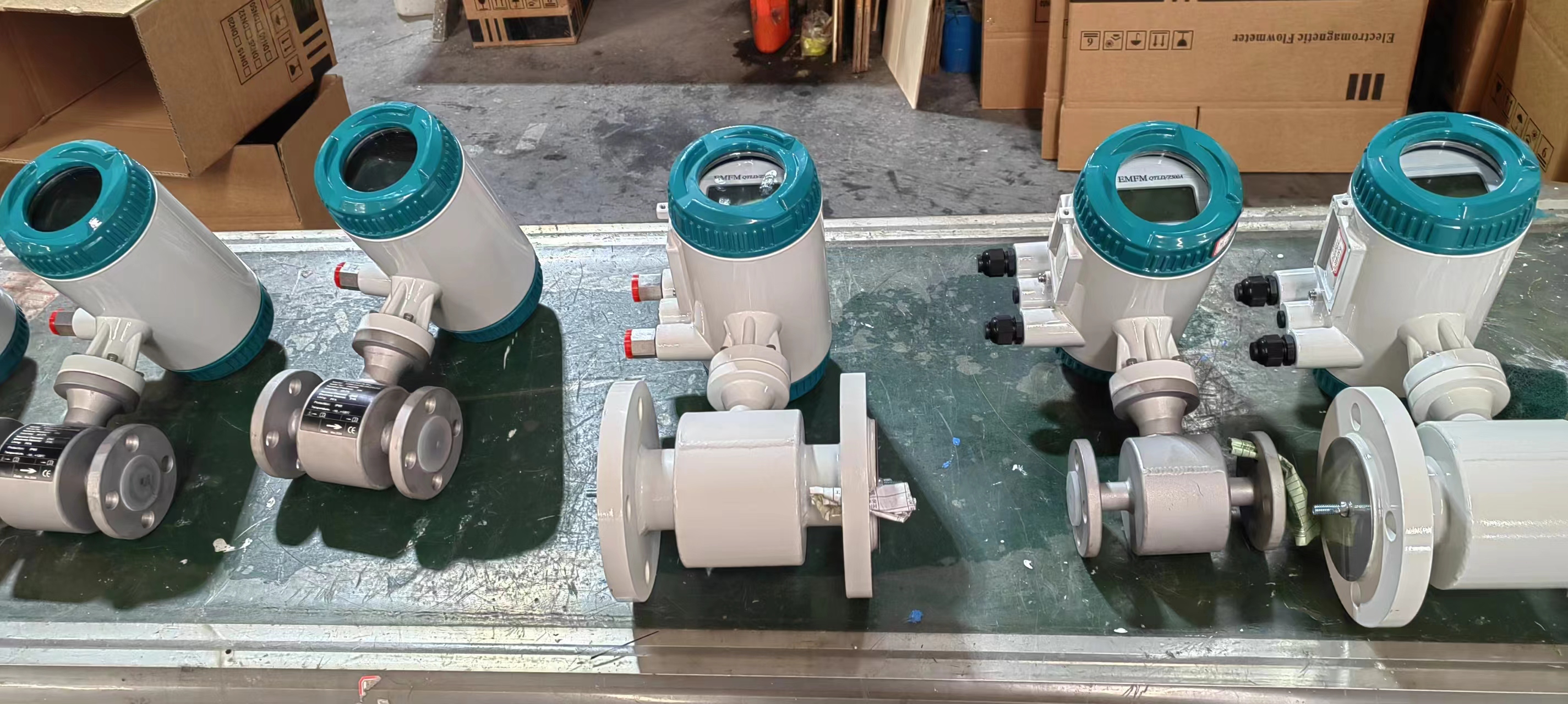

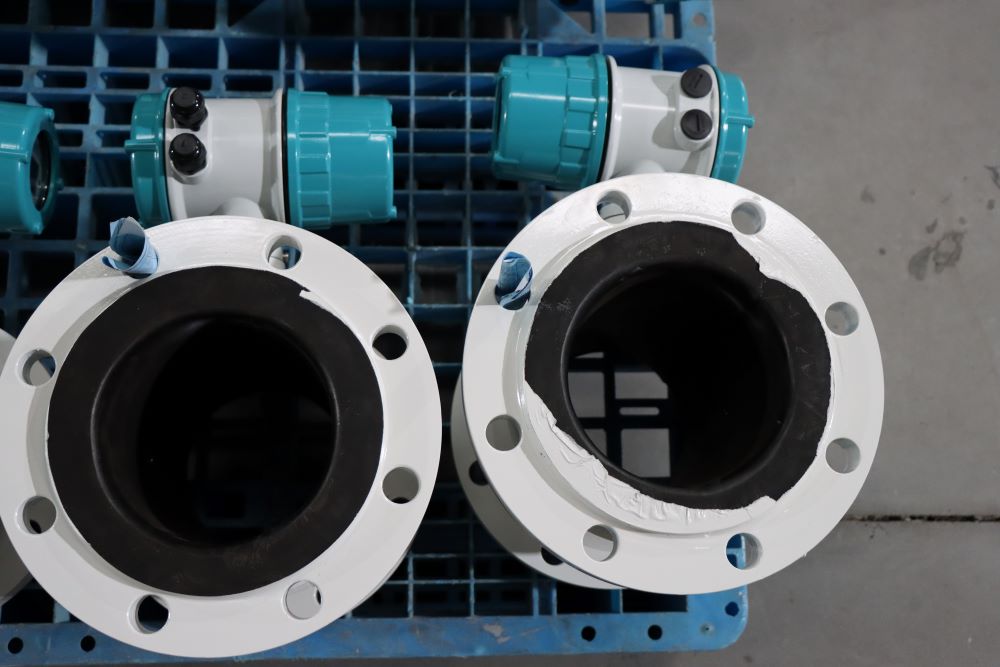

Electromagnetic flowmeter is a high precision, high reliability and long service life flow meter, so in the design of product structure, material selection, development of technology, production assembly and factory testing and other processes in every link we are very meticulous. Instrument with backlight wide temperature Chinese LCD display, functional and practical, intuitive display, easy to operate and use, in addition, we design 4-6 multi-electrode structure, further ensure the measurement accuracy and no grounding ring at any time, reduce the size of the instrument and installation and maintenance trouble. General industrial electromagnetic flowmeter measured medium flow rate of 2 ~ 4m/s is appropriate, in special cases, the minimum flow rate should not be less than 0.2m/s, the maximum should not be greater than 8m/s. If the medium contains solid particles, the usual flow rate should be less than 3m/s to prevent excessive friction between the lining and the electrode; For viscous fluid, the flow rate can be selected to be greater than 2m/s, and the larger flow rate helps to automatically eliminate the effect of viscous material attached to the electrode, which is conducive to improving the measurement accuracy.

Electromagnetic flowmeters cannot measure liquids with very low conductivity, such as petroleum products and organic solvents. Do not measure gases, vapors and liquids containing more and larger bubbles. General-purpose EMF cannot be used for liquids at higher temperatures due to the lining material and electrical insulation material limitations; Some models are used for liquids that are too low than room temperature, and the insulation is damaged by condensation (or frost) on the outside of the measuring tube.

-.jpg)

-.jpg)