Compressed Air Thermal Mass Flow Meter for Hot Air in Steel Mills

When applying a thermal mass flowmeter, several key points need to be considered to ensure accurate and reliable measurement. Here are some important factors to pay attention to:

Fluid Properties: Understand the properties of the fluid being measured, such as temperature, pressure, density, viscosity, and composition. These properties can affect the performance and accuracy of the thermal mass flowmeter.

Flow Range: Determine the expected flow range of the application. Choose a thermal mass flowmeter that is suitable for the anticipated flow rates to ensure accurate measurement across the entire range.

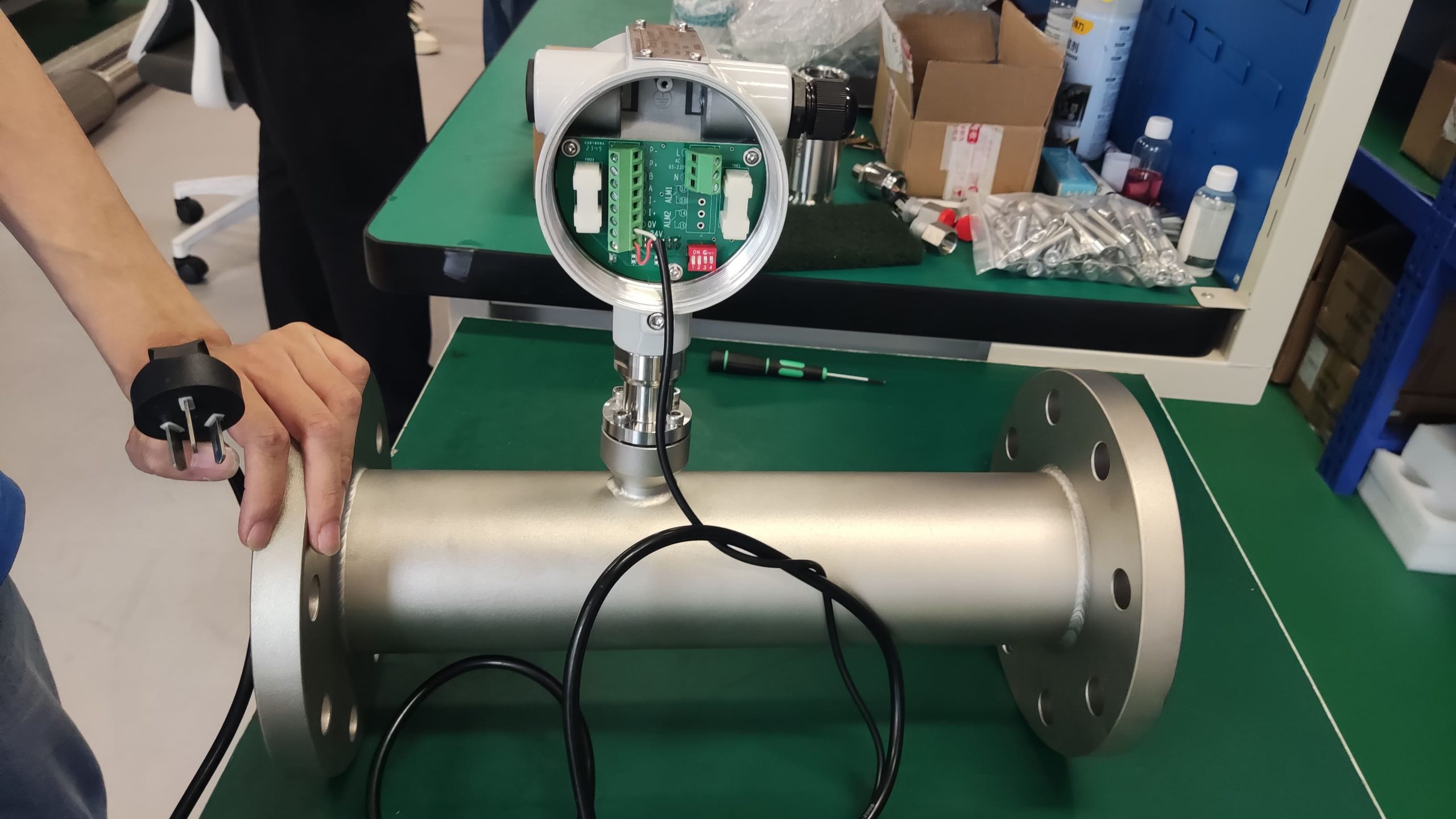

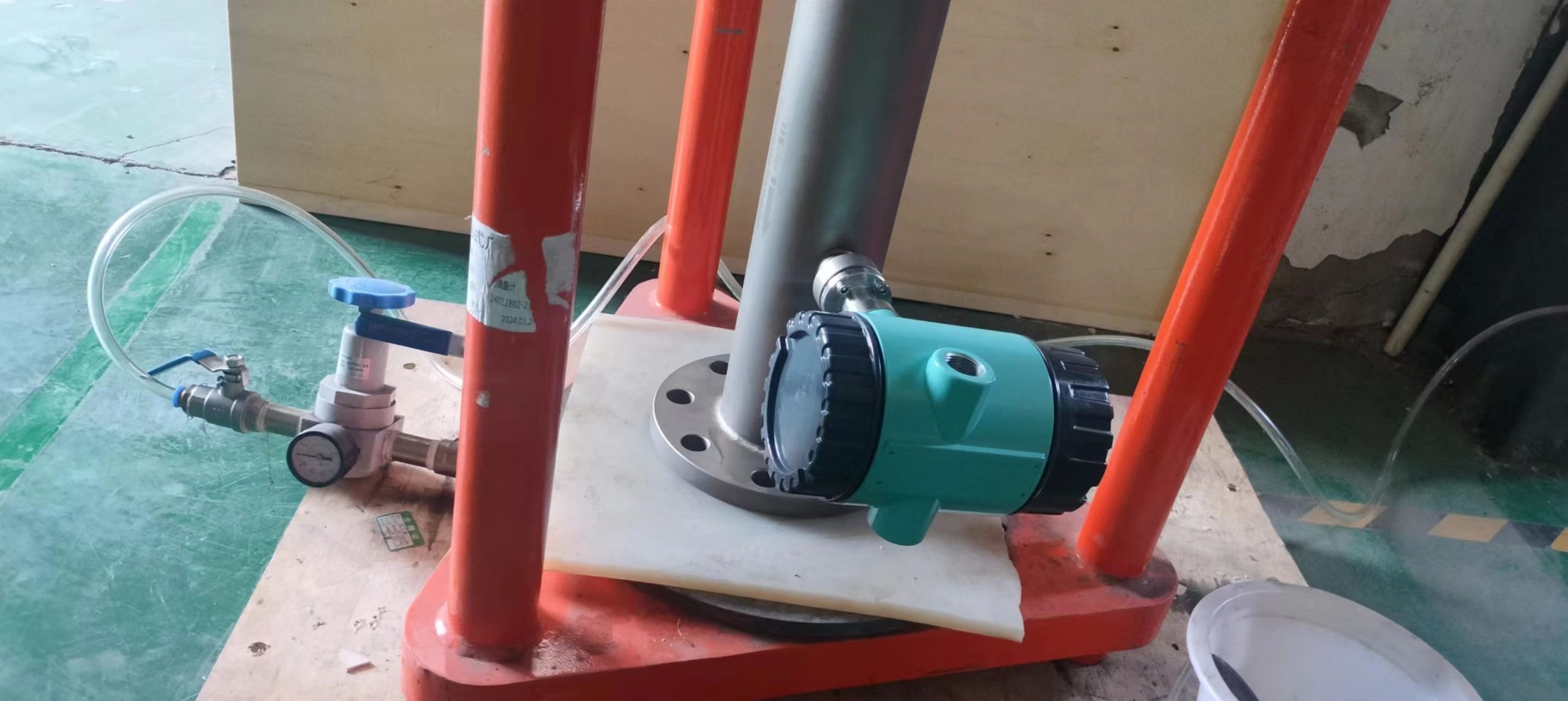

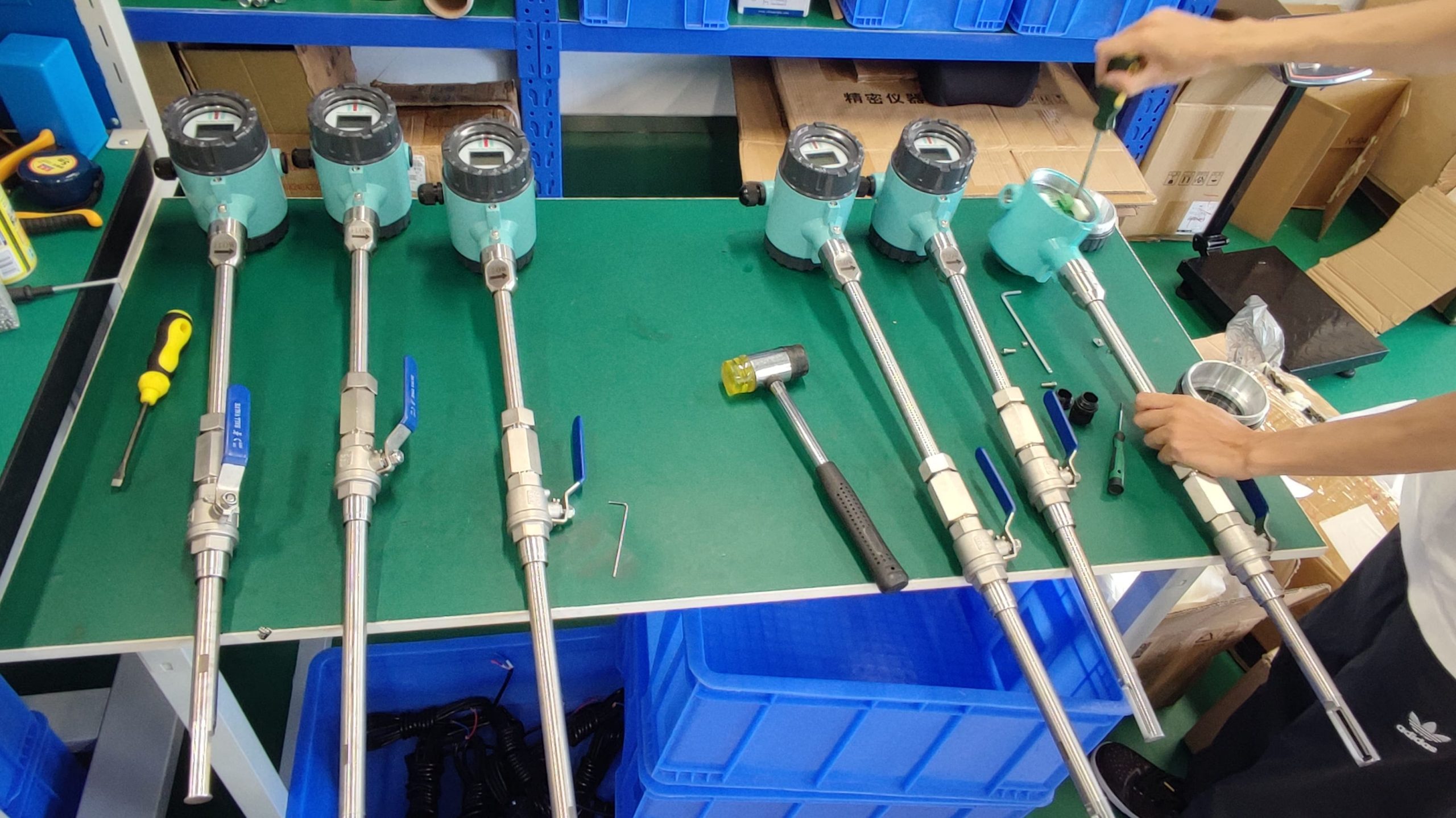

Installation Orientation: Install the flowmeter according to the manufacturer’s recommendations regarding orientation, such as vertical or horizontal placement. Improper orientation can affect the performance of the flowmeter.

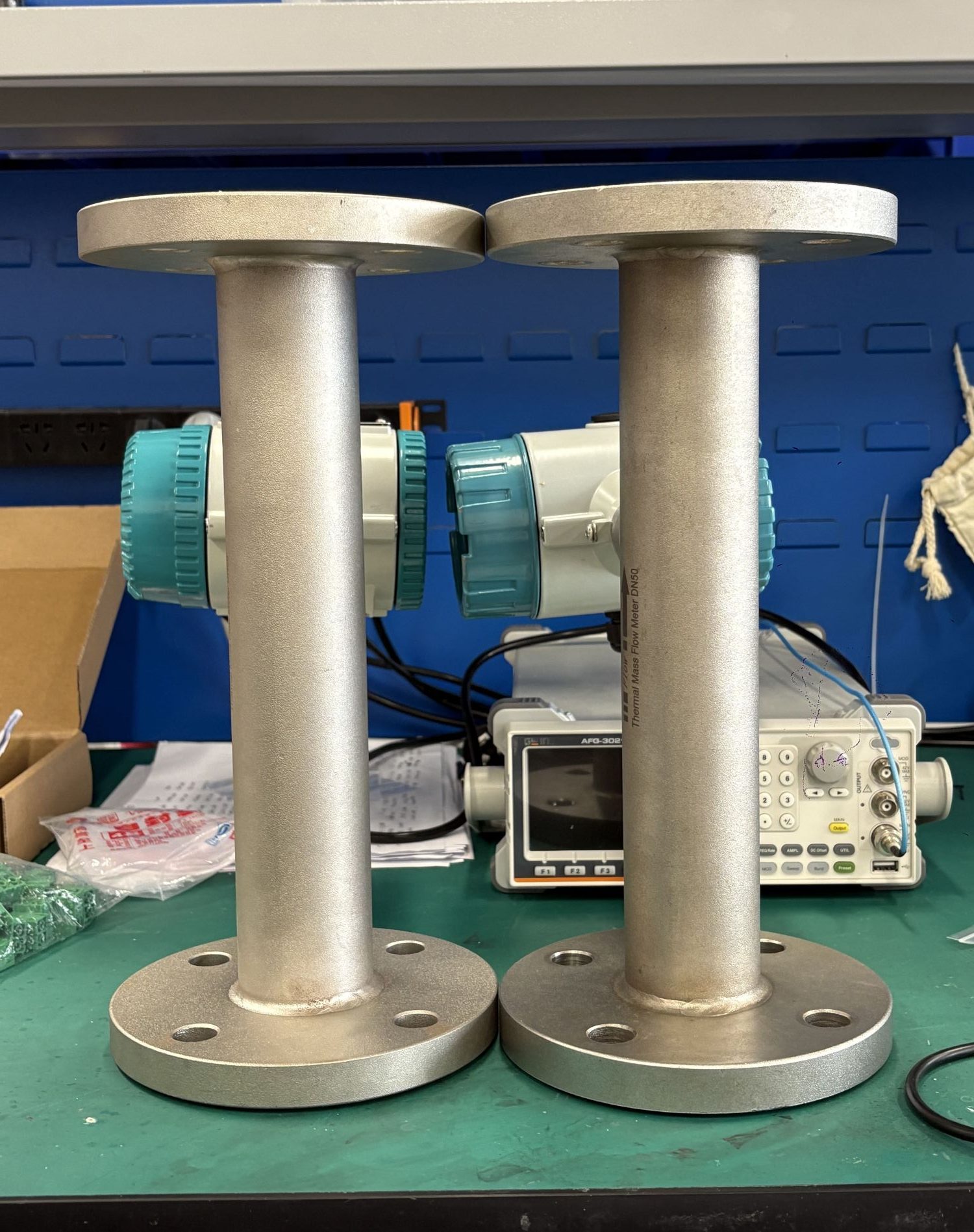

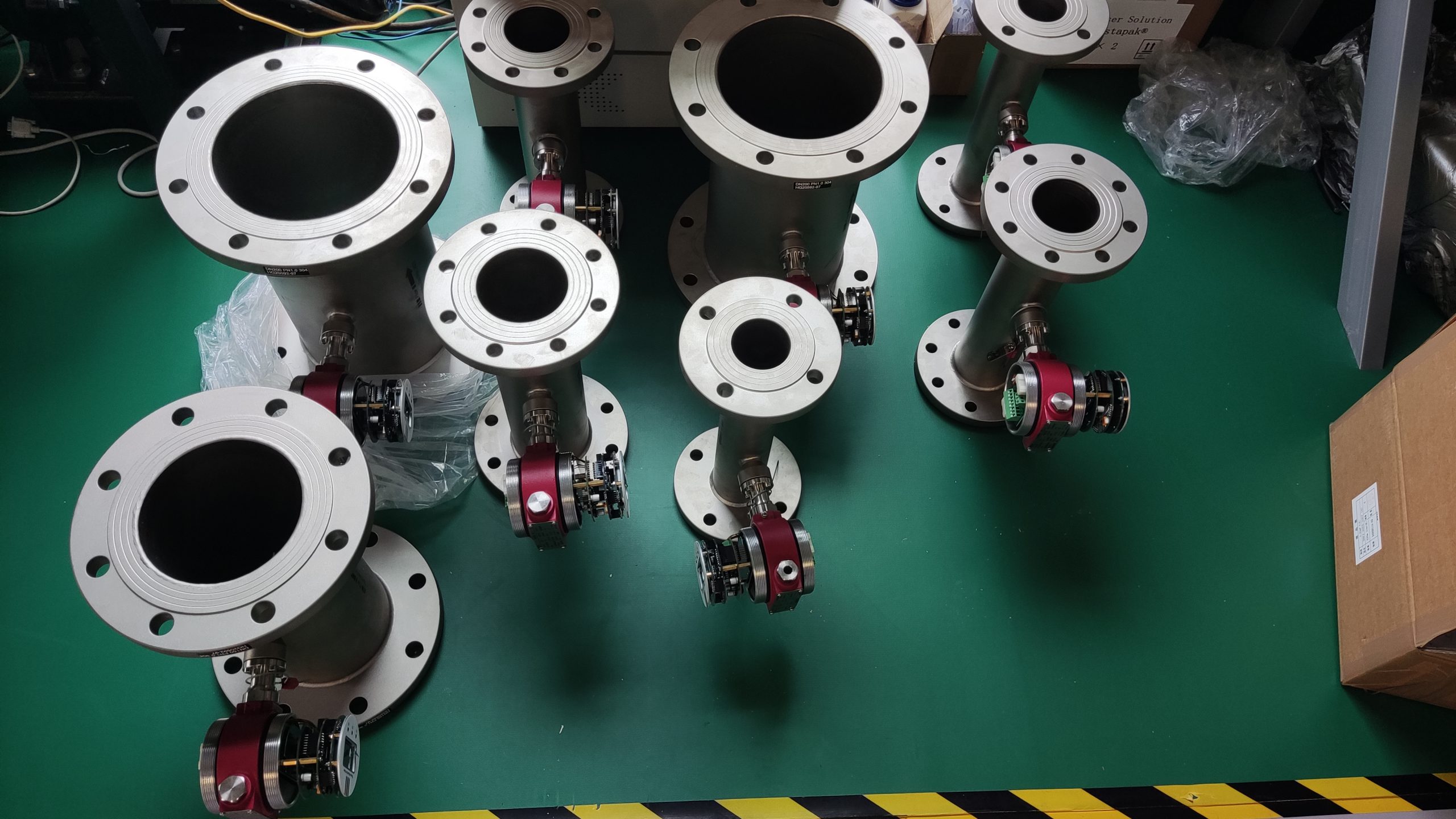

Pipe Diameter and Flow Profile: Ensure that the pipe diameter is compatible with the size of the thermal mass flowmeter. Additionally, consider the flow profile within the pipe, as uneven flow profiles can affect measurement accuracy.

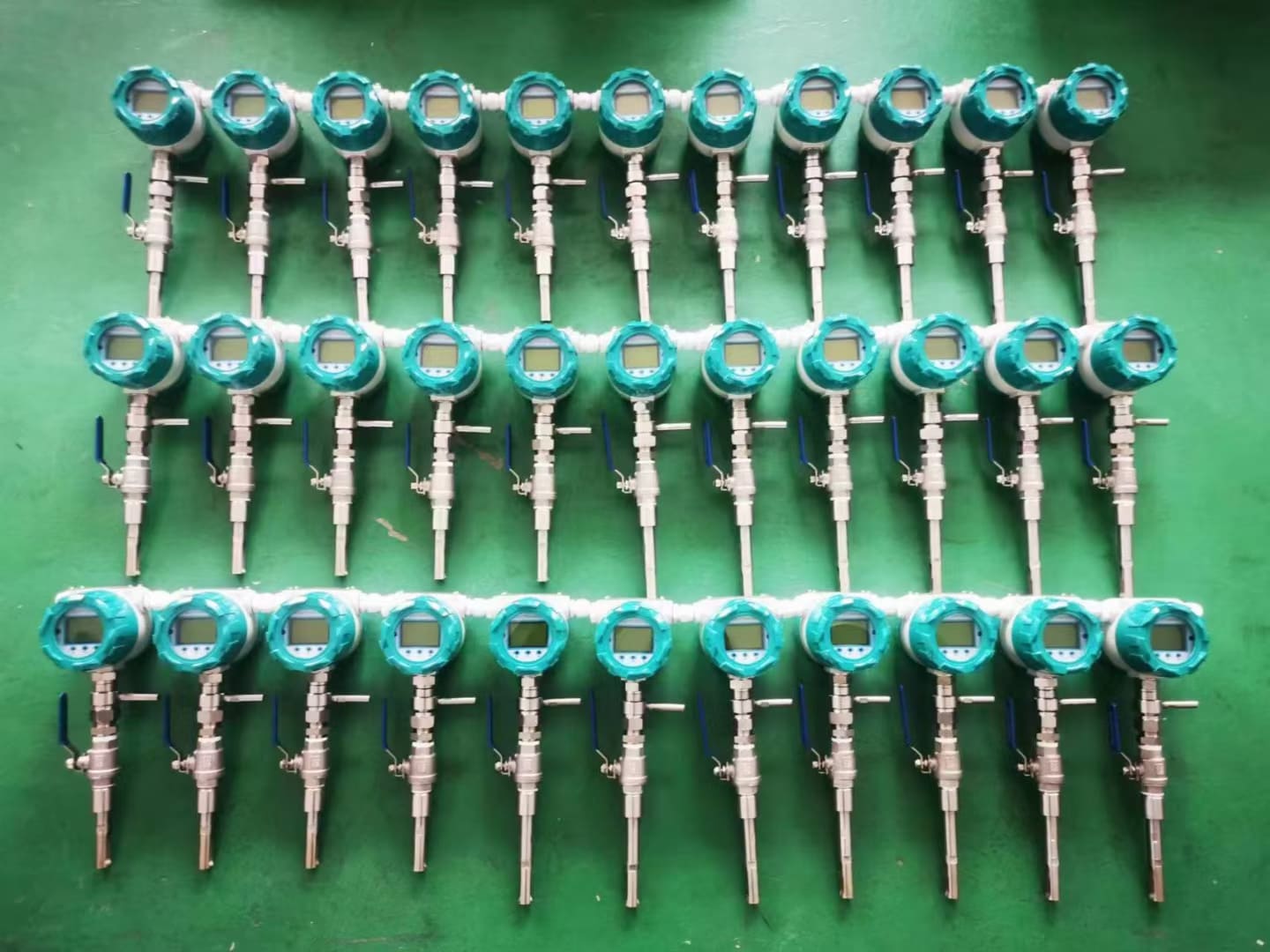

Calibration: Calibrate the flowmeter regularly according to the manufacturer’s recommendations or industry standards. Proper calibration is essential for maintaining accurate measurements over time.

Ambient Conditions: Consider the ambient conditions surrounding the flowmeter, such as temperature, humidity, and vibration. Extreme environmental conditions can affect the performance of the flowmeter and may require additional measures for protection or compensation.

Mounting Location: Select an appropriate mounting location for the flowmeter, ensuring sufficient straight pipe lengths both upstream and downstream of the flowmeter to minimize flow disturbances and turbulence.

Power Supply: Provide a stable and reliable power supply to the flowmeter to ensure continuous operation. Check the power requirements specified by the manufacturer.

Data Communication: Determine the requirements for data communication and integration with control systems or data acquisition systems. Ensure compatibility and proper configuration for seamless data transmission.

Maintenance: Establish a regular maintenance schedule for the flowmeter, including inspection, cleaning, and calibration. Proper maintenance helps prolong the lifespan and ensures accurate performance of the flowmeter.

Safety Considerations: Adhere to safety protocols during installation, operation, and maintenance of the flowmeter to prevent accidents or damage to equipment.

Manufacturer Guidelines: Follow the manufacturer’s guidelines and instructions provided in the user manual for proper installation, operation, and maintenance of the thermal mass flowmeter.

By considering these factors and following best practices, you can effectively apply thermal mass flowmeters in various industrial and commercial applications while ensuring accurate and reliable measurement of fluid flow.