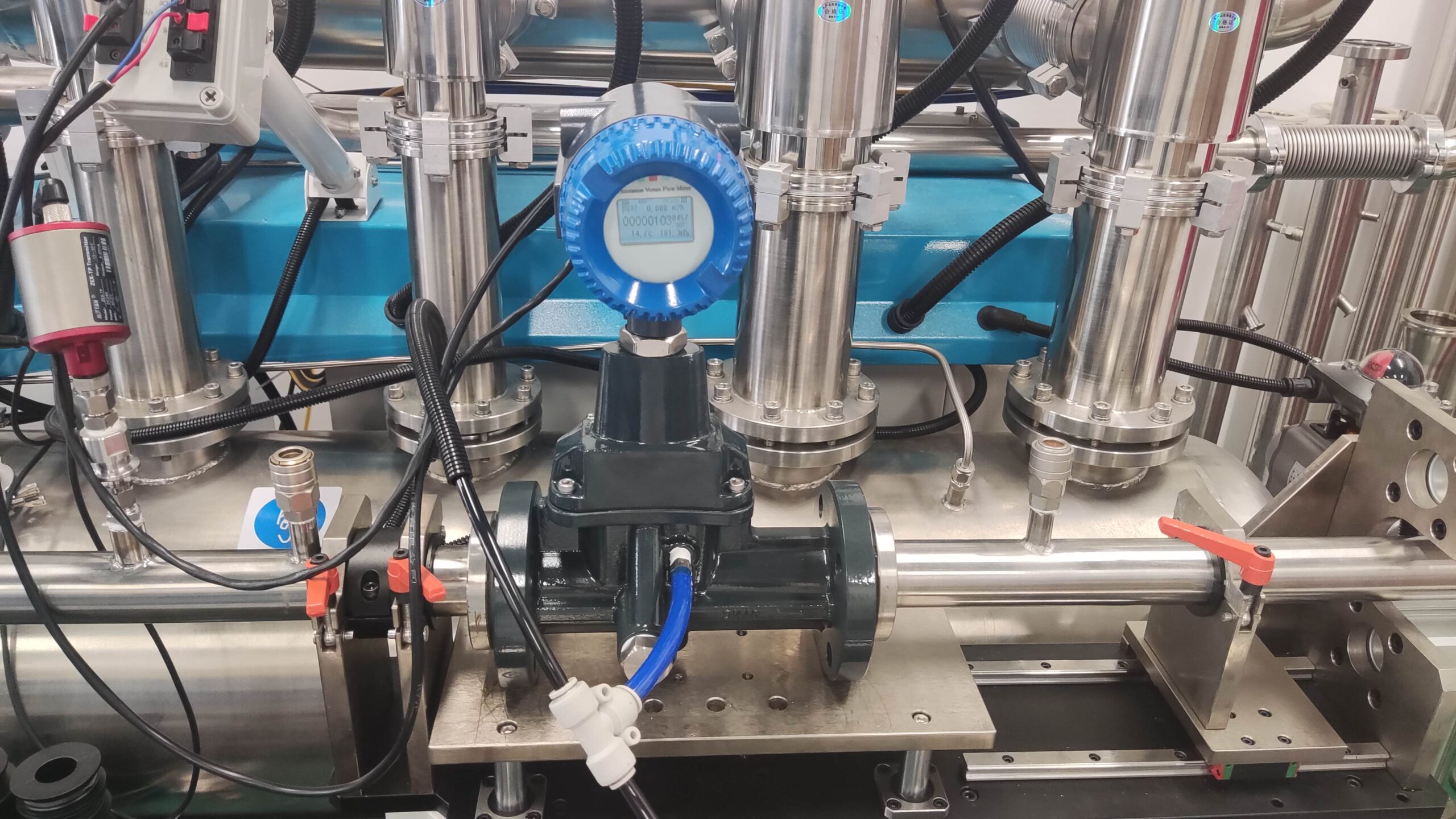

Common faults and solutions of precession vortex flow meter

Precession vortex flowmeter fault phenomenon and treatment:

1. Precession vortex flowmeter has no output signal

Reason: there is no medium in the pipeline or the flow rate is lower than the lower limit; Check whether the power supply and output line are correctly connected; Check whether the preamplifier circuit is damaged; Check the input amplifier circuit for damage.

Treatment method: improve the medium flow to meet the flow requirements; Correct wiring; Replace the preamplifier; Replace the damaged component of the output amplifier circuit.

2. Precession vortex flowmeter has output

Reason: poor grounding of the flowmeter or strong ground and other ground interference; Amplifier sensitivity is too high or generates self-excitation; The piezoelectric sensor and the preamplifier are in poor contact or disconnected; Unstable power supply, poor filtering and other electrical interference.

Treatment method: properly connect the ground wire, eliminate interference; Replace the preamplifier; Check the circuit to make it normal; Repair or replace the power supply to remove interference.

3, precession vortex flowmeter display instability

Reason: the sensitivity of the amplifier is too high or too low, there is a leakage pulse phenomenon; The depth position of piezoelectric sensor is not adjusted correctly. Unsteady vibration or electrical interference at the site where the flowmeter is installed; Poor grounding; The installation position is incorrect, there is a bend in front of the flowmeter.

Treatment method: replace the preamplifier; Re-adjust the depth position of the voltage electric sensor; Eliminate unstable vibration and interference; Check the grounding line to make it normal; Change the installation position.

4. The cumulative flow indication is inconsistent with the actual flow

Reason: the meter coefficient input is not normal; The normal flow of the user is lower than or higher than the normal flow range of the selected flowmeter; The precession vortex flowmeter itself is out of range; Fluid cavitation phenomenon; The Silenor number of the pipeline is not in the range of 2×104 ~ 7×106.

Processing method: re-calibrate, use the function button to set and adjust, make it correct; Adjust the pipeline flow to make it normal; Re-calibrate; Reduce fluid ground pressure loss to avoid bubbles.

5, switching display error

Cause: Check whether the wiring is correct; Check whether the switch button contact is good; Check whether the wiring of the display screen is good; Check whether the display is.

Treatment method: correct wiring; Replacement button; Correctly connect the display line; Replace the display.

The above is about the precession vortex flow meter fault phenomenon and treatment methods, if there are other questions, you can contact Aister instrument at any time, we are ready to answer for you.