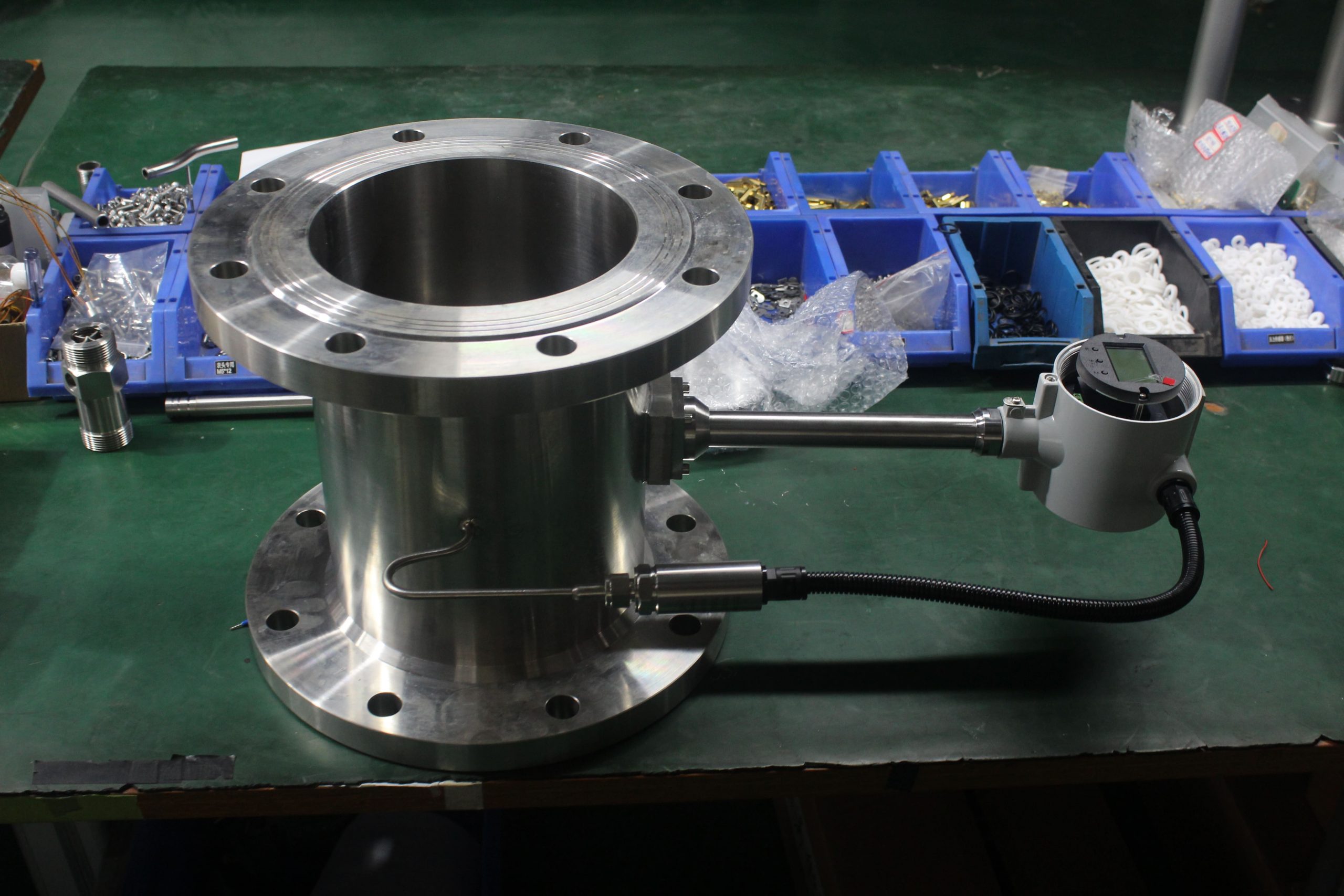

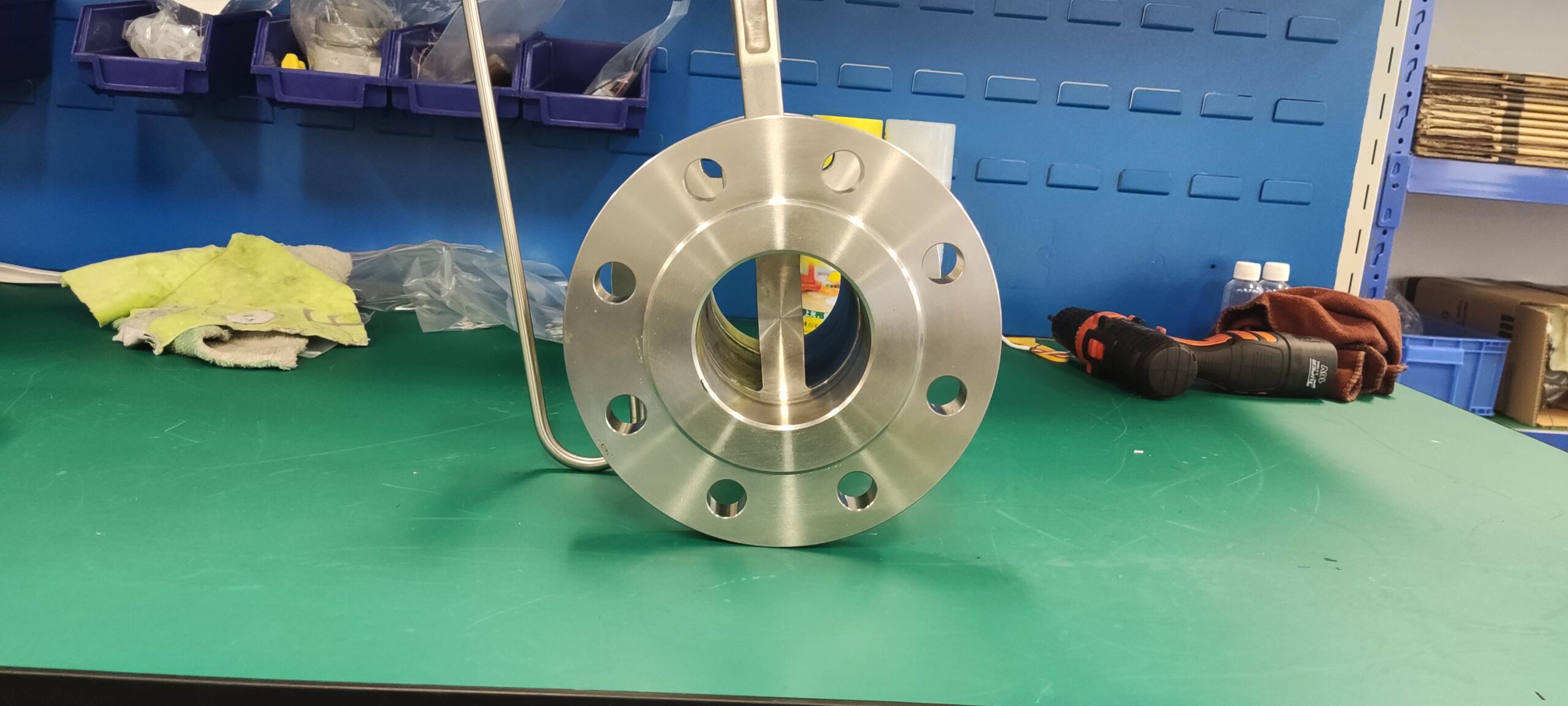

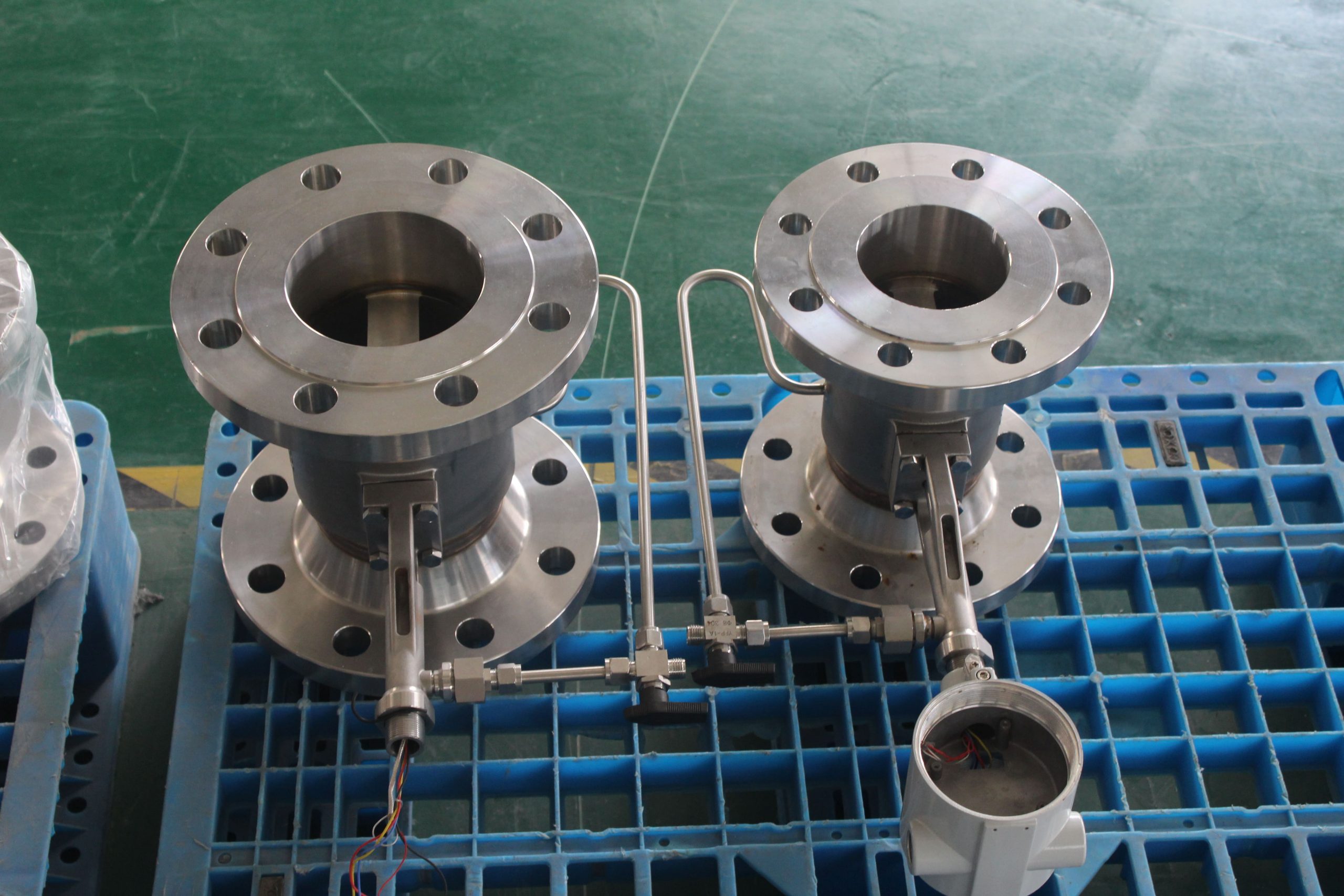

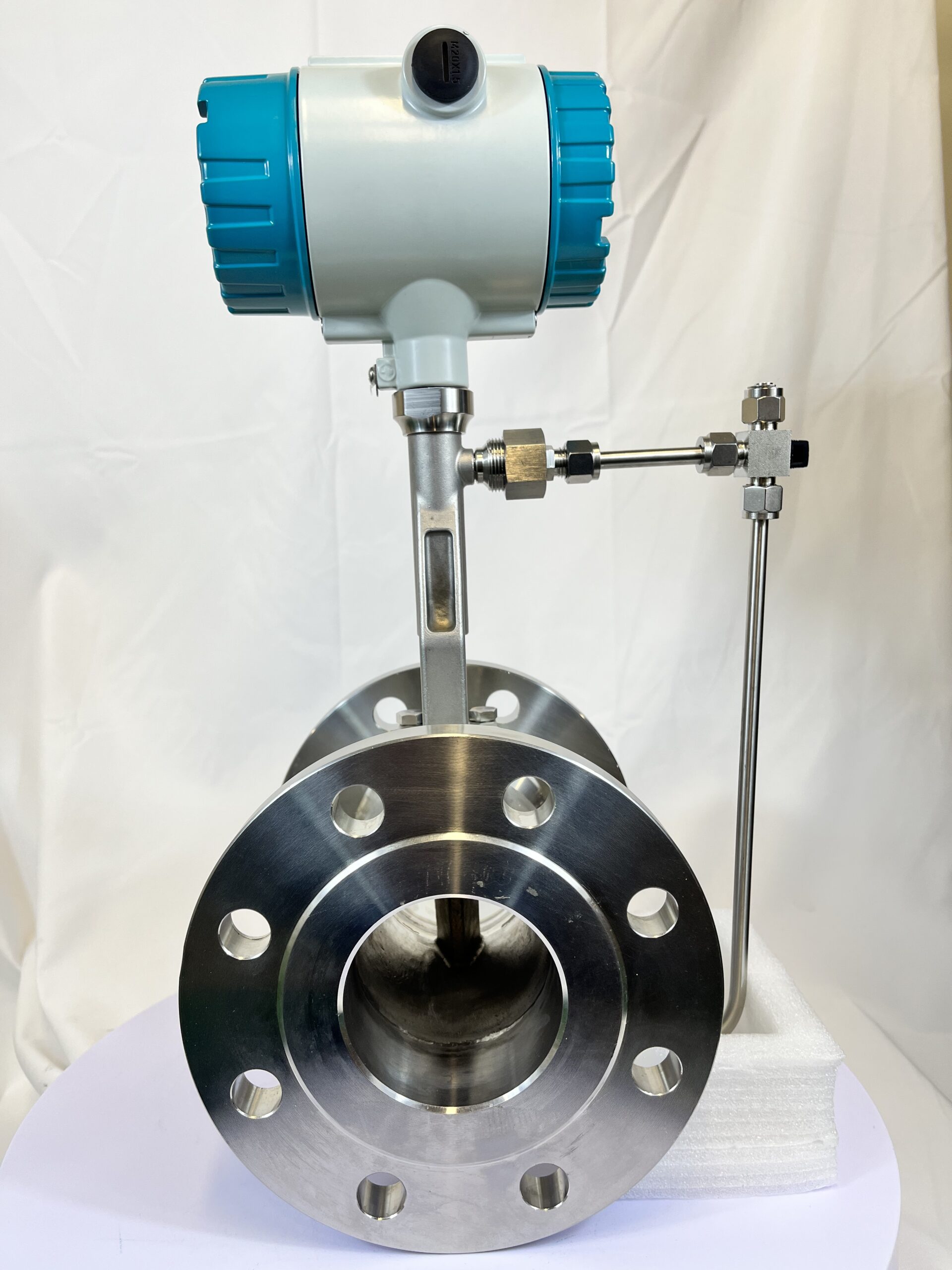

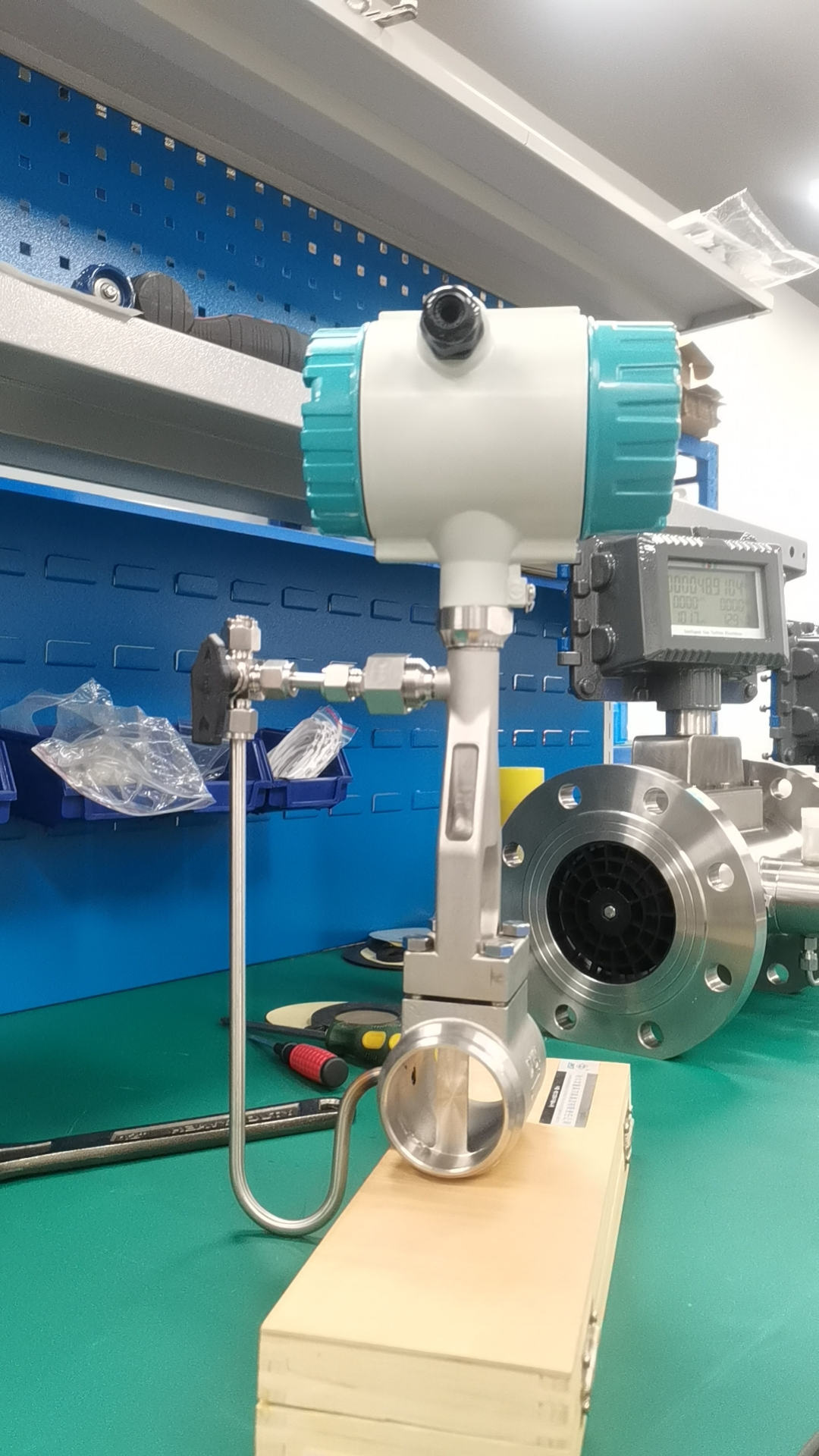

CO2 Air Gas Hot Steam Flow Meter Vortex Boiler Steam Flowmeter Pressure Transmitter

Precautions for installation and use of vortex flow meter

(1) On-site installation and maintenance must comply with the warning of “Do not open the cover of explosive gas objects”, and turn off the external power supply before opening the cover.

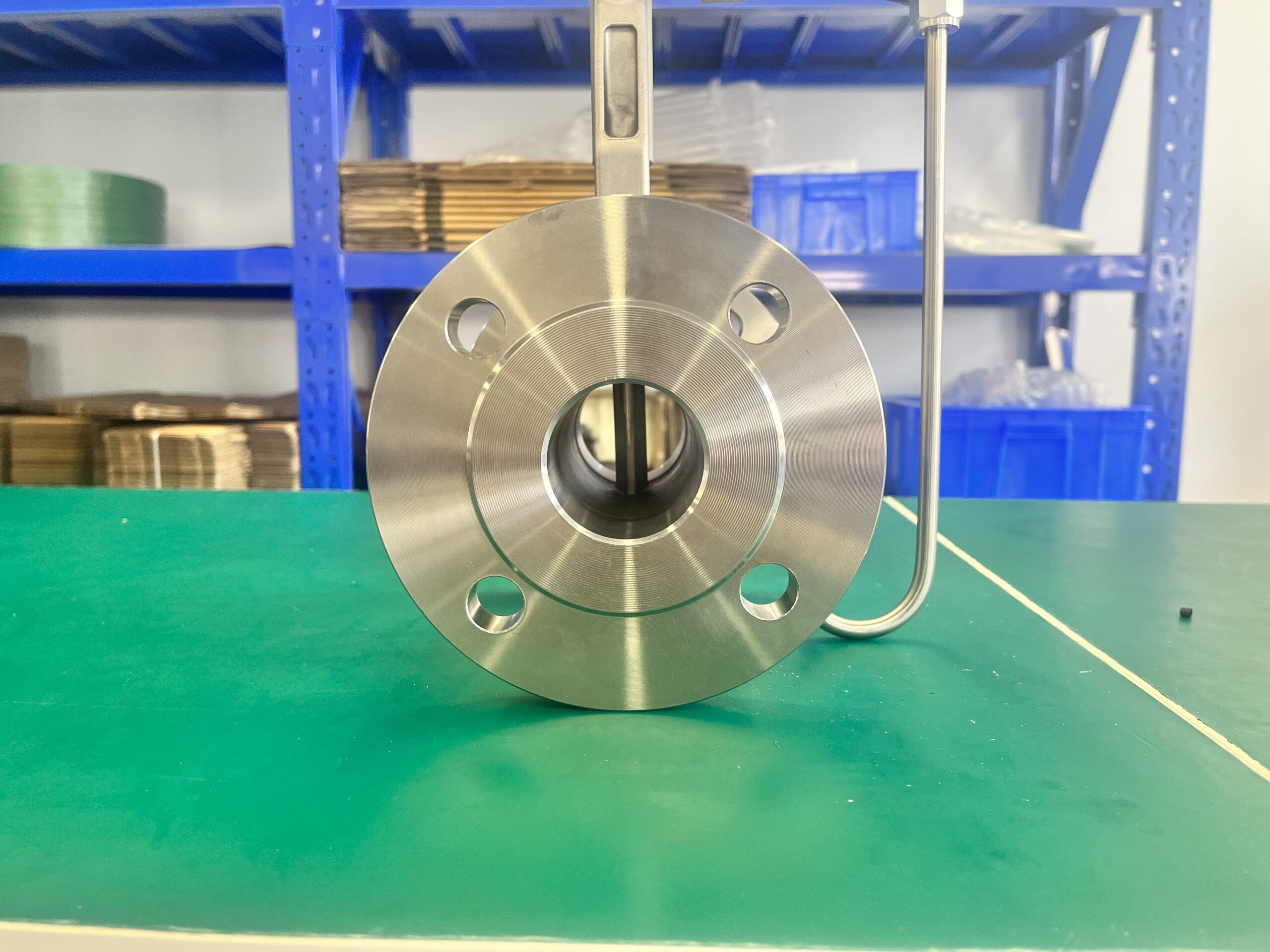

(2) Check before the on-site installation is completed

a. The flange, valve, pressure hole, temperature hole and connection on the main pipe and bypass pipe should have no leakage phenomenon;

b. Whether the vibration of the pipeline conforms to the specifications;

c. Is the sensor installed correctly? Is the electrical connection of each part good?

(3) Power on static debugging

When the power is blocked, the converter should have no output, the instantaneous flow indication is zero, and the cumulative flow does not change, otherwise, first check whether the signal line is shielded or grounded.

Good, or strong vibration of the pipeline and introduce interference signals. If it is confirmed that this is not the case, the potentiometer in the converter can be adjusted to reduce the amplifier gain or increase the shaping current.

Path trigger level until output is zero.

(4) Flow dynamic debugging

Close the by-pass valve, open the upstream and downstream valves, after the flow is stable, the converter outputs continuous pulse with uniform pulse width, the flow indicator is stable without jumping, adjust the valve opening,

The output changes accordingly, otherwise it should be carefully checked and adjusted until the output of the instrument is both correctly triggered and no leakage pulse.