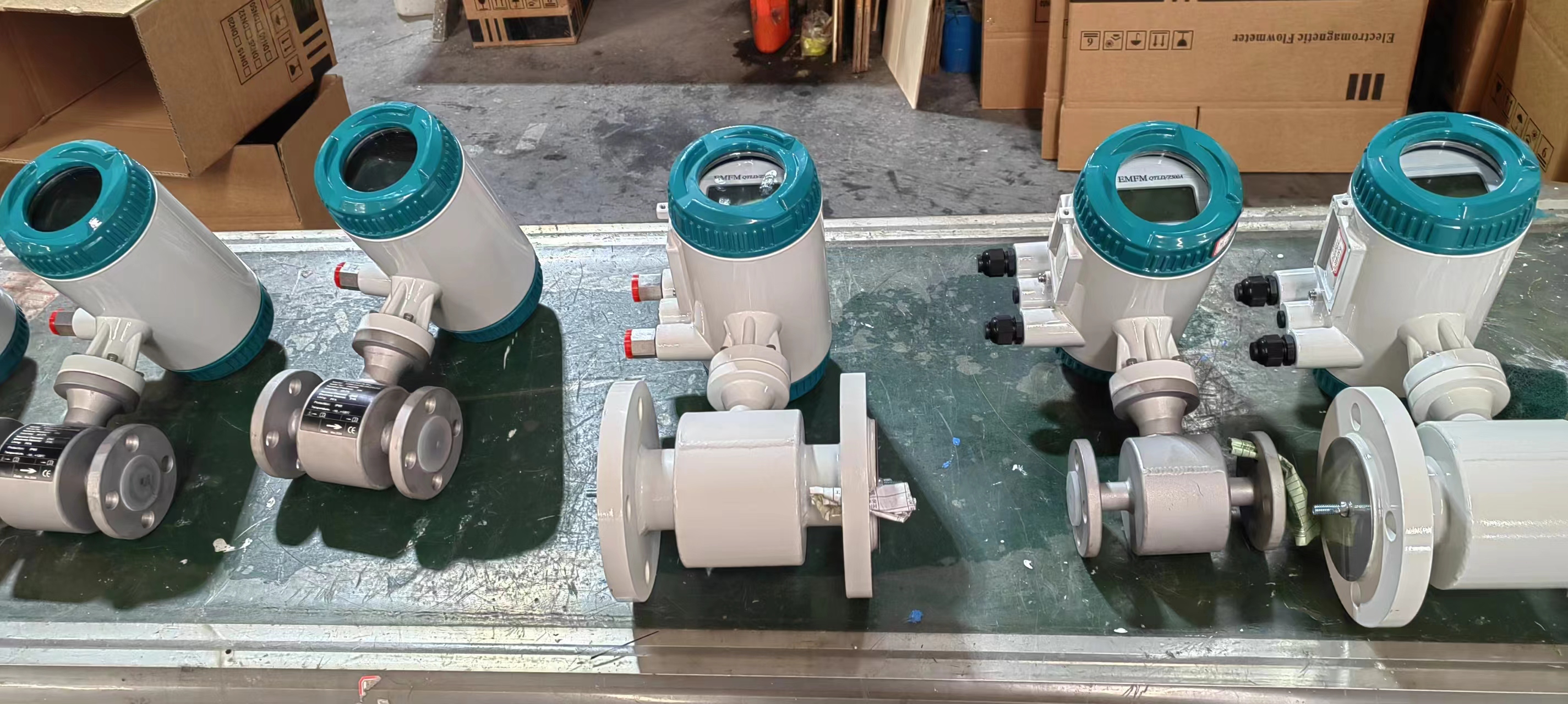

Choose one type electromagnetic flow meter or split type electromagnetic flow meter?

Electromagnetic flowmeter is based on the principle of electromagnetic induction, through the electromotive force generated by the conductive fluid through the external magnetic field to measure the fluid flow meter. Electromagnetic flowmeter is widely used because of its high precision and good stability, so the choice of integrated or split electromagnetic flowmeter is particularly important.

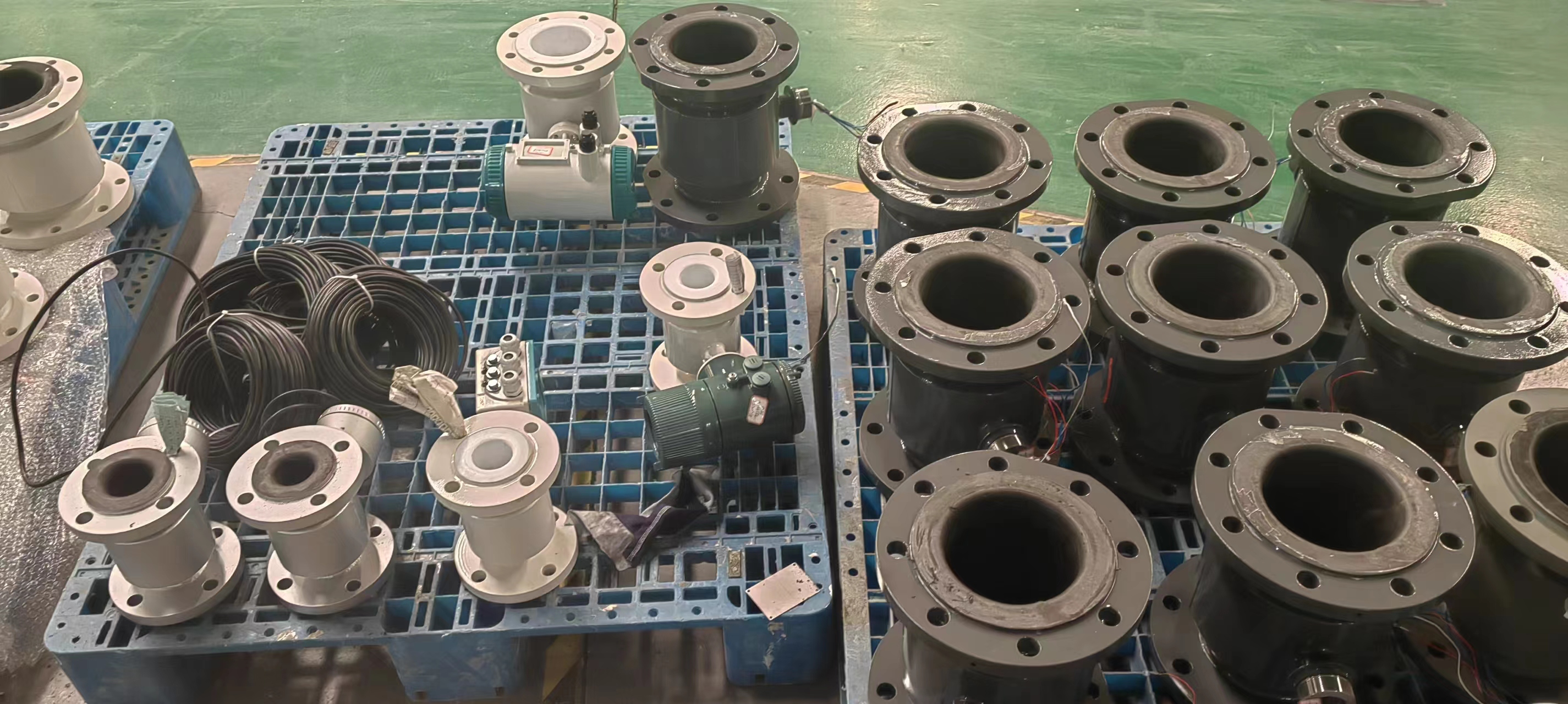

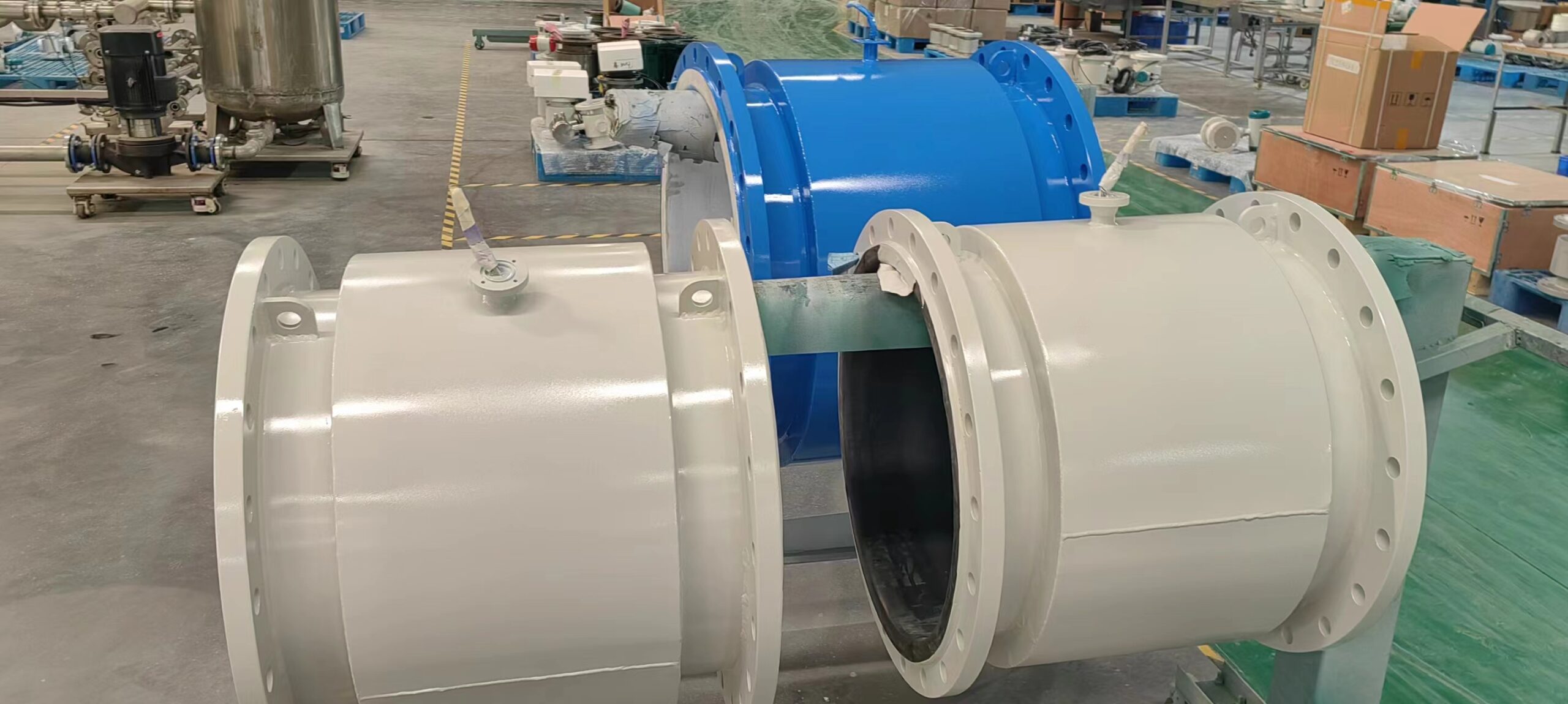

Reasonable selection of electromagnetic flowmeter is a prerequisite for the application of electromagnetic flowmeter, then what kind of electromagnetic flowmeter to choose is still determined by the irrational and chemical properties of the conductive fluid control that needs to be measured. Several factors that need to be considered by users are: the universal diameter of the electromagnetic flowmeter (i.e., dn), the size of the flow range, the flow rate range (maximum value, minimum value), the material of the lining, the material of the electrode, and the output signal.

So whether to use integrated electromagnetic flowmeter or split electromagnetic flowmeter, how to judge?

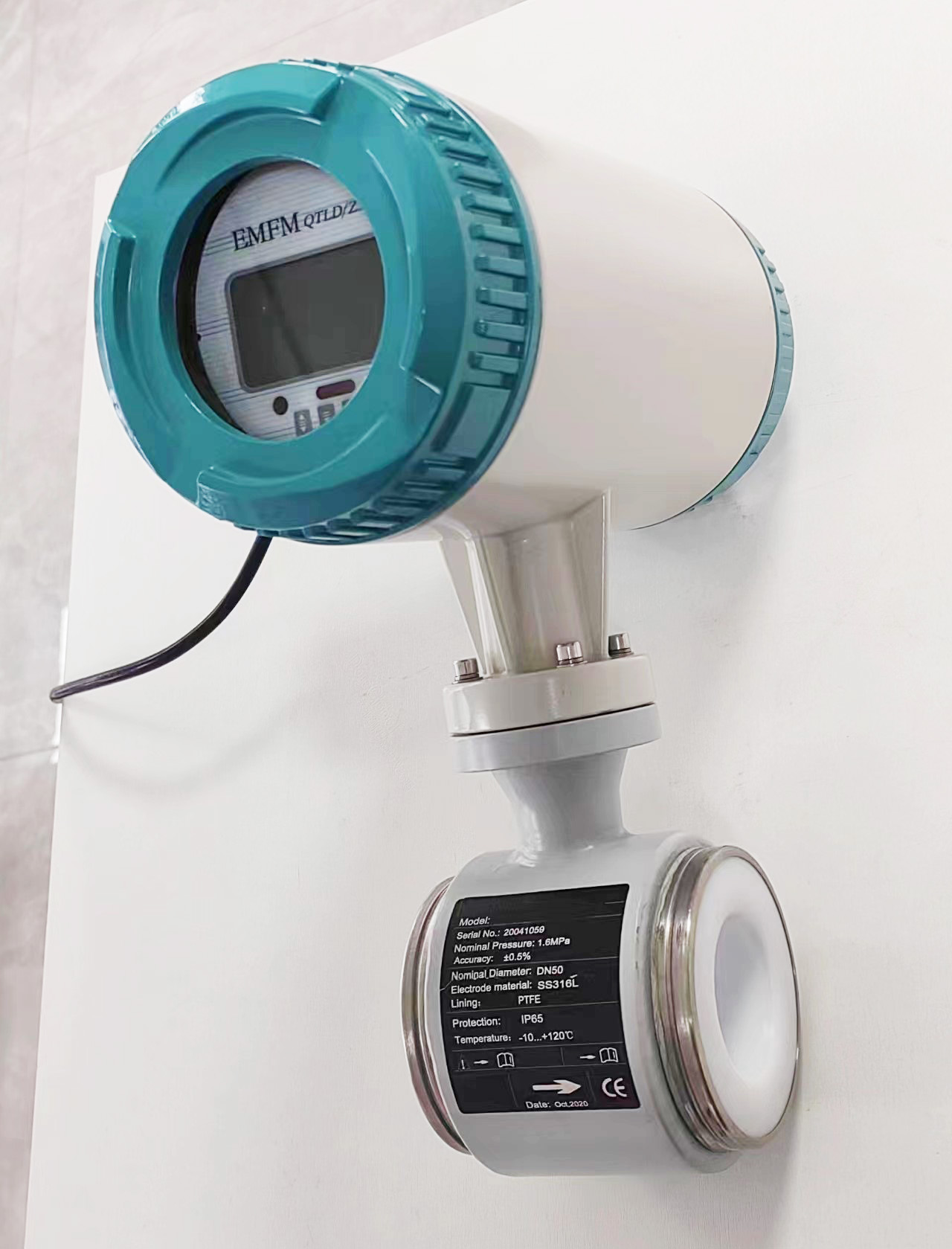

First of all, a type of electromagnetic flowmeter is as the name suggests that the sensor and the converter are half of a whole, we should pay attention to when choosing a type of electromagnetic flowmeter is not better, if the environment is normal now, no noise interference or other corrosive factors, you can use a type of electromagnetic flowmeter.

Here we talk about what will be the use of fractional electromagnetic flowmeters, mainly divided into the following five situations:

1. The ambient temperature, that is, the temperature of the installation site of the electromagnetic flowmeter is higher (more than 60 degrees Celsius);

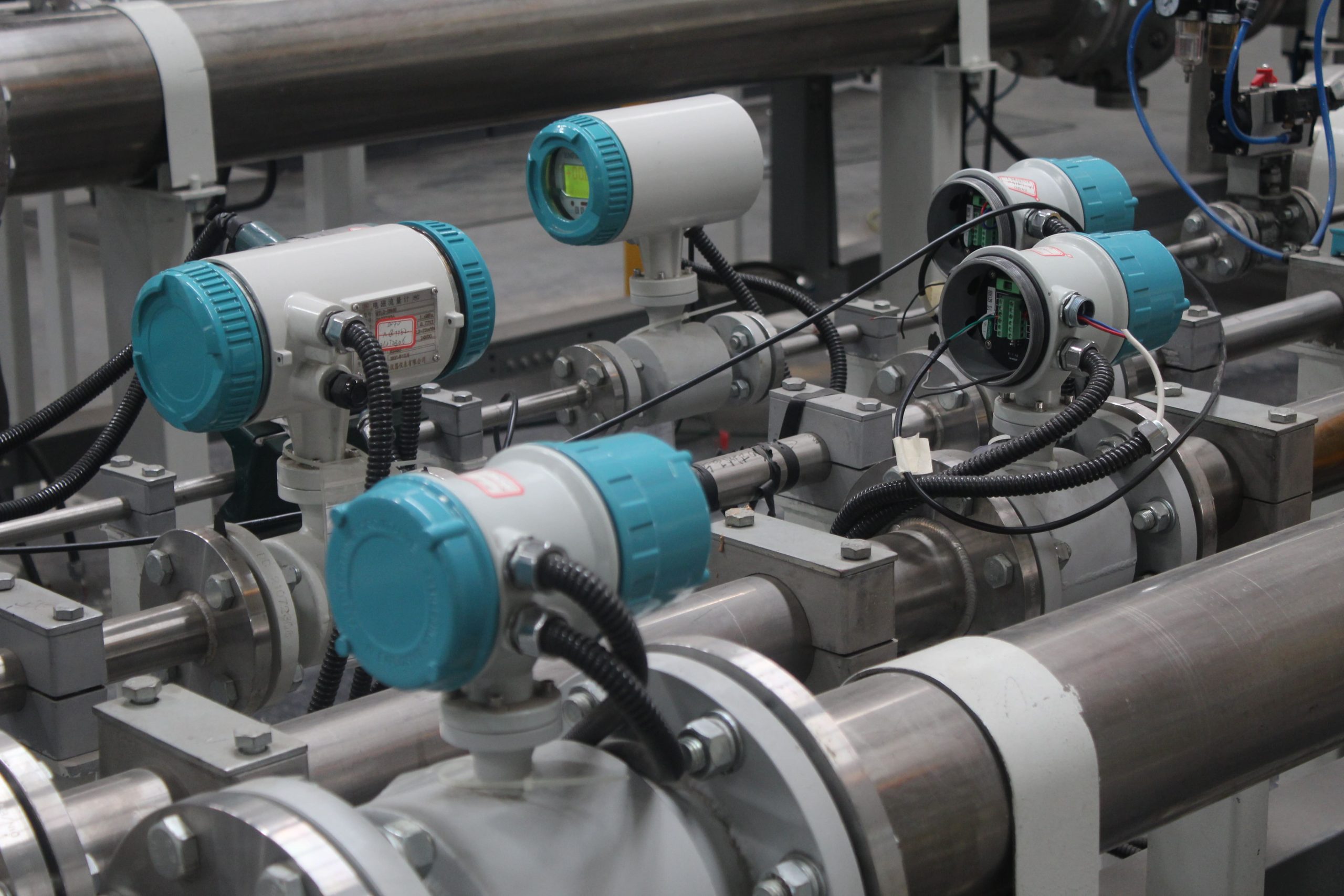

2. Pipeline vibration is relatively large in the installation environment on site;

3. Corrosive installation environment, that is, it will cause corrosion to the sensor body;

4. The humidity of the site is relatively large or the corrosive gas is relatively strong;

5. The installation place of the electromagnetic flowmeter is an inconvenient place such as high altitude or underground.

In addition, special attention should be paid to: when ordering the partial type electromagnetic flowmeter, it should be explained to the manufacturer that the cable connection distance of the sensor and the converter is generally not greater than 20 meters.

-.jpg)