CE Approved Coriolis Mass Flow Meter High Viscosity Mass Flowmeter

Installing Coriolis mass flowmeters involves several steps to ensure accurate measurement and proper functionality. Here’s a general guide for installing Coriolis mass flowmeters:

Select Installation Location: Choose an appropriate location for installing the flowmeter. It should be easily accessible for maintenance and calibration, and away from sources of vibration or excessive heat that could affect accuracy.

Prepare Piping: Prepare the piping system where the flowmeter will be installed. Ensure the pipe is clean and free from debris that could affect flow measurement accuracy. Consider installing straight pipe runs upstream and downstream of the flowmeter to minimize flow disturbances.

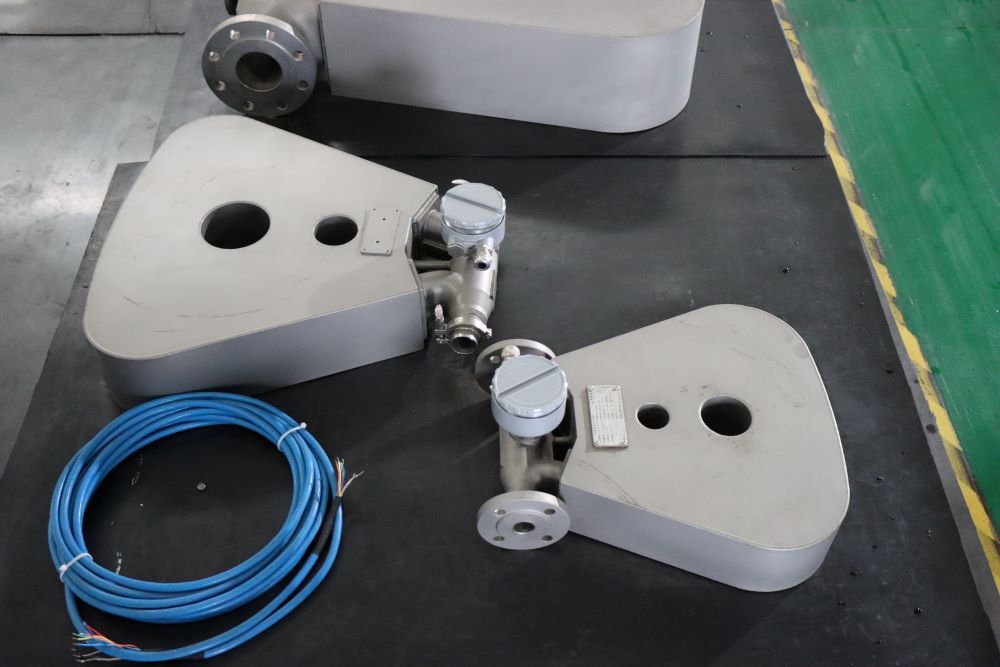

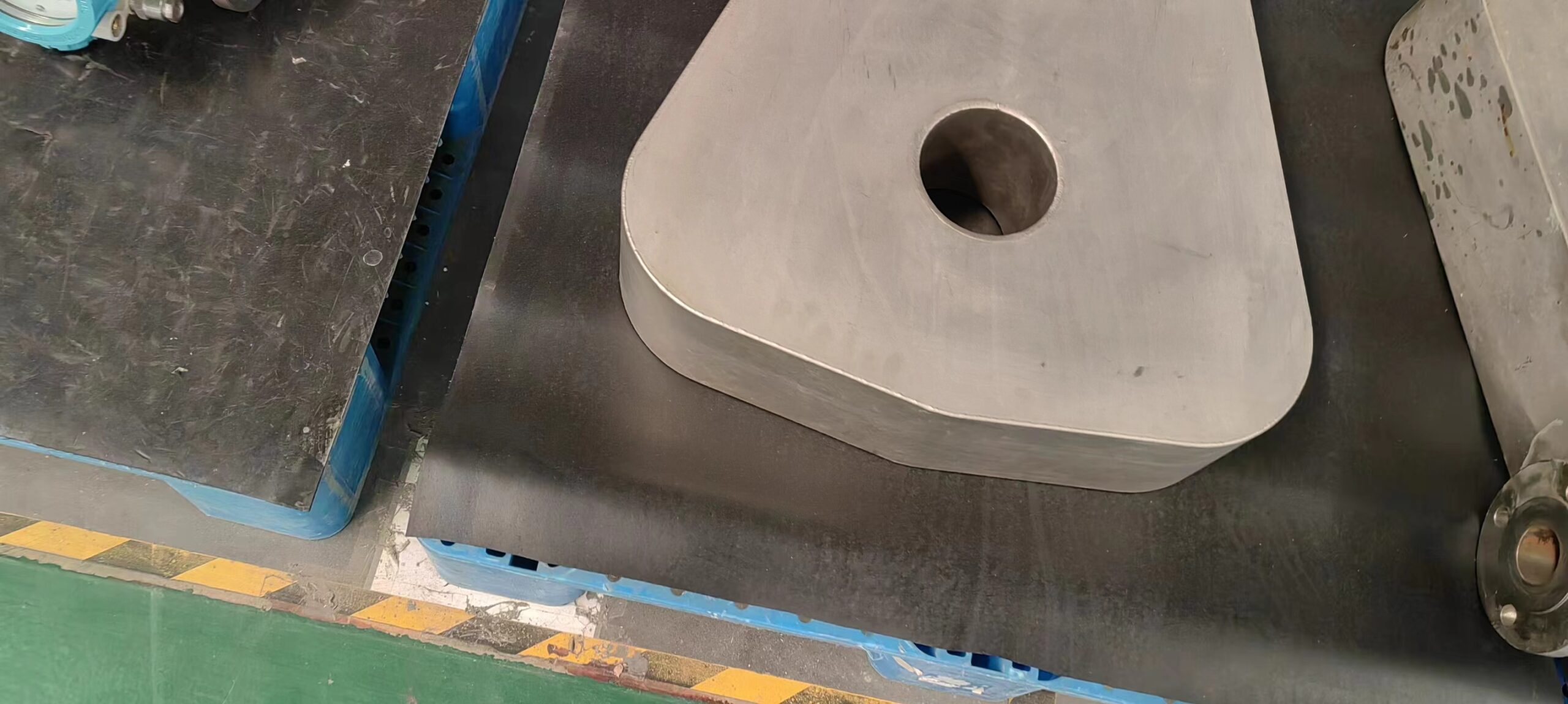

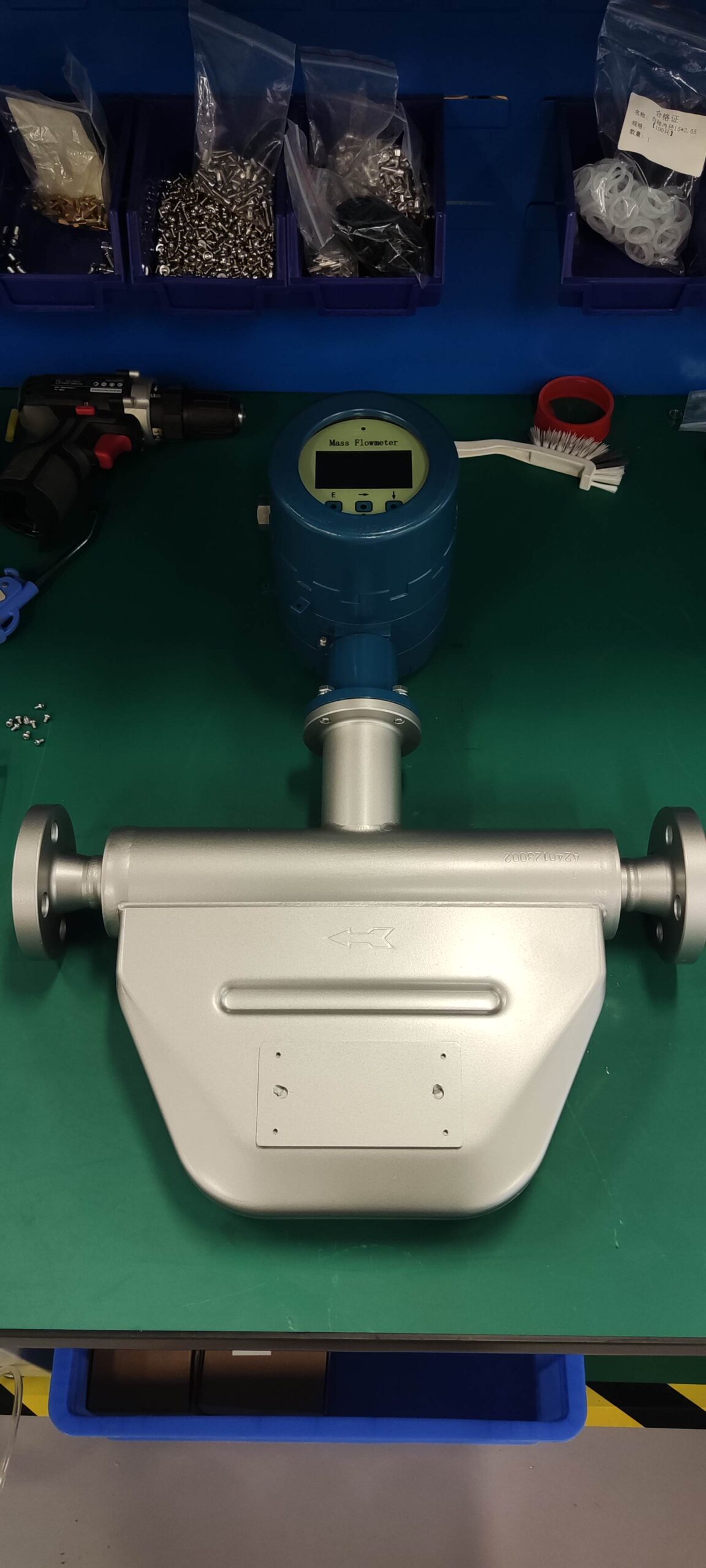

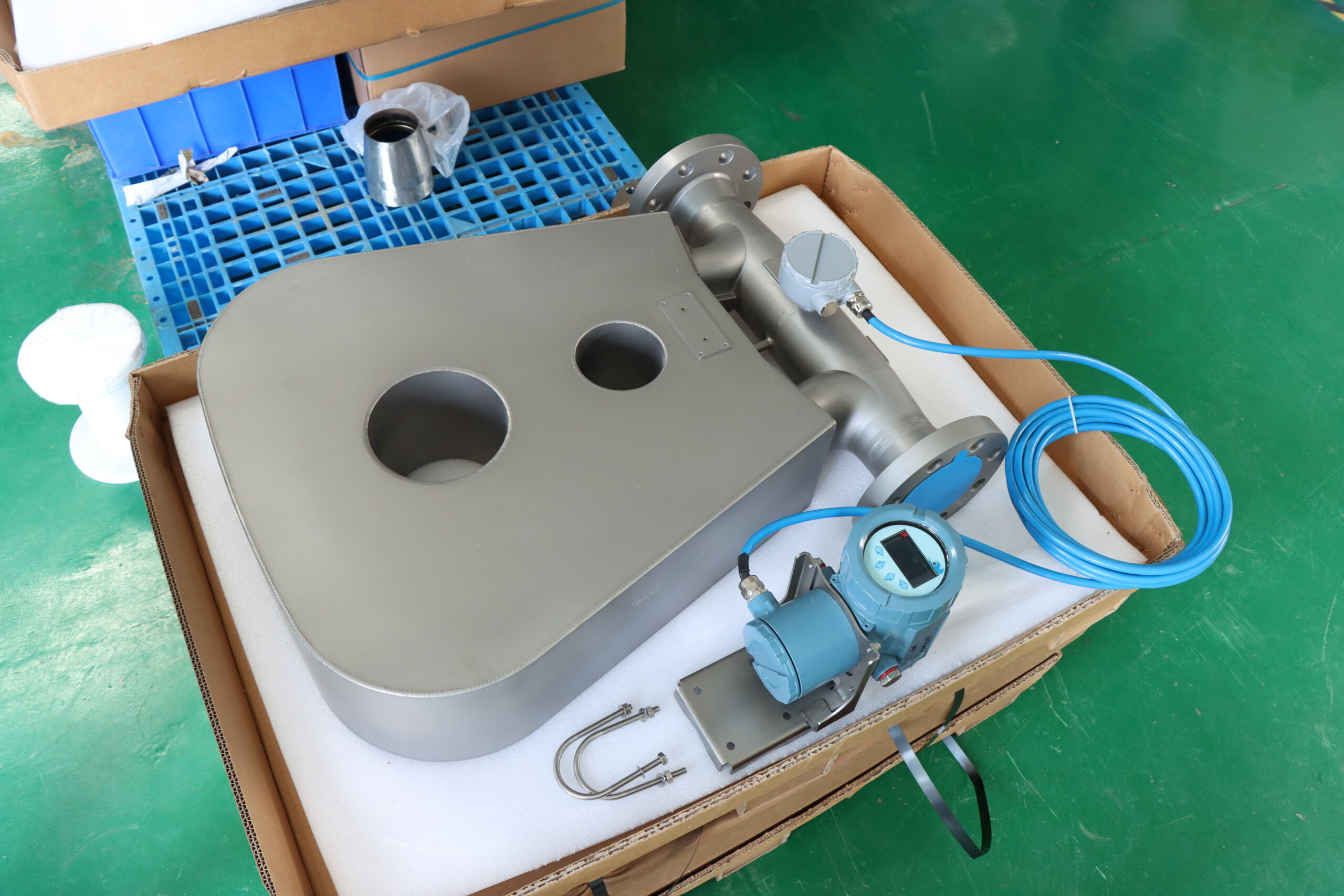

Mount the Flowmeter: Mount the Coriolis mass flowmeter securely in the desired location using appropriate mounting hardware. Ensure the flowmeter is aligned properly with the piping system and oriented according to the manufacturer’s instructions.

Connect Fluid Lines: Connect the fluid lines to the inlet and outlet ports of the flowmeter. Use appropriate fittings, gaskets, and seals to ensure leak-free connections. Follow the manufacturer’s recommendations for pipe size, material, and connection type.

Electrical Connections: If the flowmeter requires electrical connections for power or signal transmission, make sure to connect the wiring according to the manufacturer’s instructions. Ensure proper grounding to prevent electrical interference.

Calibration: Before putting the flowmeter into operation, it’s essential to calibrate it to ensure accurate measurement. Follow the calibration procedures provided by the manufacturer or use a certified calibration service to calibrate the flowmeter.

Commissioning: Once the flowmeter is installed and calibrated, perform commissioning procedures to verify its performance and functionality. Check for any leaks, monitor flow readings, and ensure the flowmeter operates as expected under normal operating conditions.

Integration with Control System: If the flowmeter is part of a larger control or monitoring system, integrate it with the system according to the manufacturer’s instructions. Configure any necessary settings or parameters to enable communication and data exchange with the control system.

Testing and Verification: Conduct testing and verification procedures to confirm that the flowmeter is measuring flow accurately and reliably. Perform periodic maintenance and verification checks to ensure ongoing performance.

Training and Documentation: Train personnel responsible for operating and maintaining the flowmeter. Provide documentation, including installation manuals, operation guides, and maintenance procedures, to ensure proper handling and care of the flowmeter over its lifecycle.

Following these steps will help ensure the successful installation and operation of Coriolis mass flowmeters for accurate flow measurement in various industrial applications. Always refer to the specific instructions provided by the flowmeter manufacturer for detailed installation procedures and best practices.