Can the thermal gas mass flow meter measure the flue gas flow

Like the flue gas, this medium has a higher temperature, contains more impurities such as solid dust, the general application of large caliber, flow rate range is relatively wide, so the measurement is more difficult, so in the selection and use of flue gas flow timing should pay attention to the characteristics of the power plant flue wind speed, pay attention to the principle of choosing sensors, It is also necessary to pay attention to the wear resistance, corrosion resistance, dirt resistance and high temperature resistance of the sensor, and select the appropriate measurement position to ensure the measurement accuracy.

The measurement of gas flow meters is a difficult problem, but we have to find a way to overcome this problem, our commonly used gas flow meters are mainly target flow meters, vortex flow meters, differential pressure flow meters, thermal gas mass flow meters and other types. Today and mainly talk about the thermal gas mass flowmeter measurement of flue gas problems.

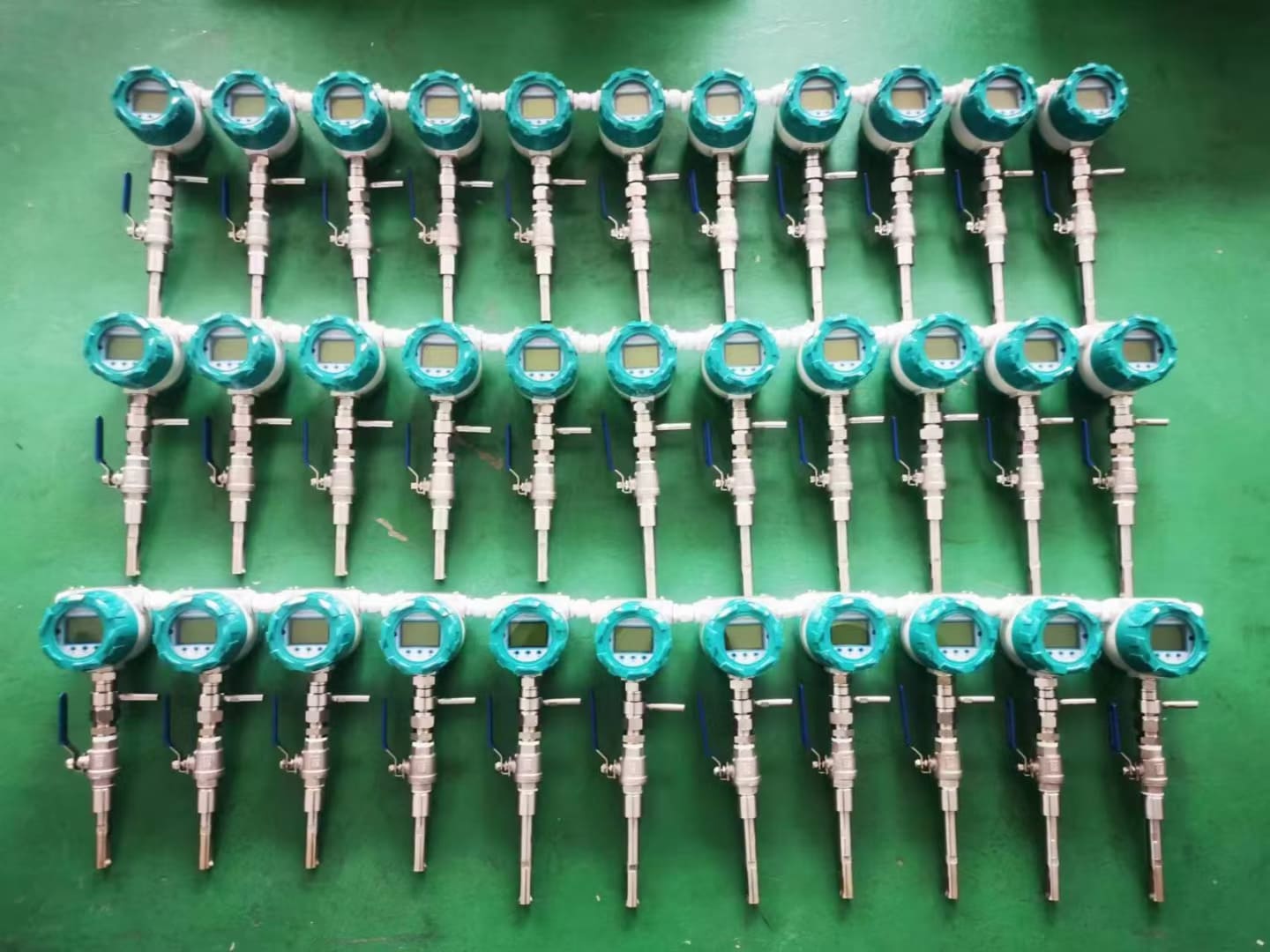

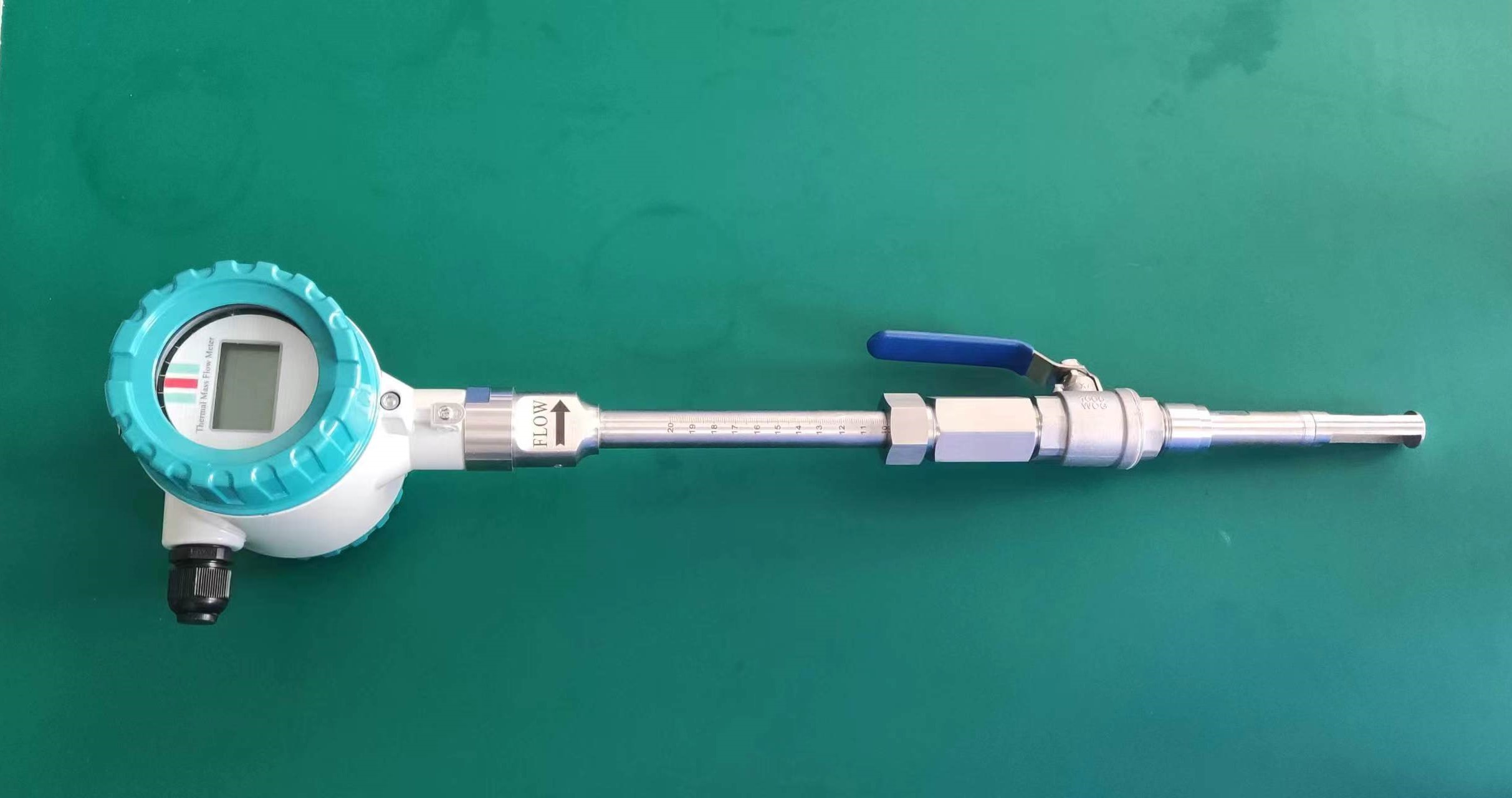

First of all, why choose a thermal gas mass flowmeter to measure flue gas flow? In the front, we said that the gas flow rate range is wide, and there is a certain corrosion, and the hot gas mass flowmeter can measure the flow rate range is 0.1Nm/s – 100Nm/s, 304 stainless steel material corrosion resistance is better, this external thermal gas mass flowmeter sensor has no moving parts and pressure sensing parts, is not affected by vibration on the measurement accuracy, good stability.

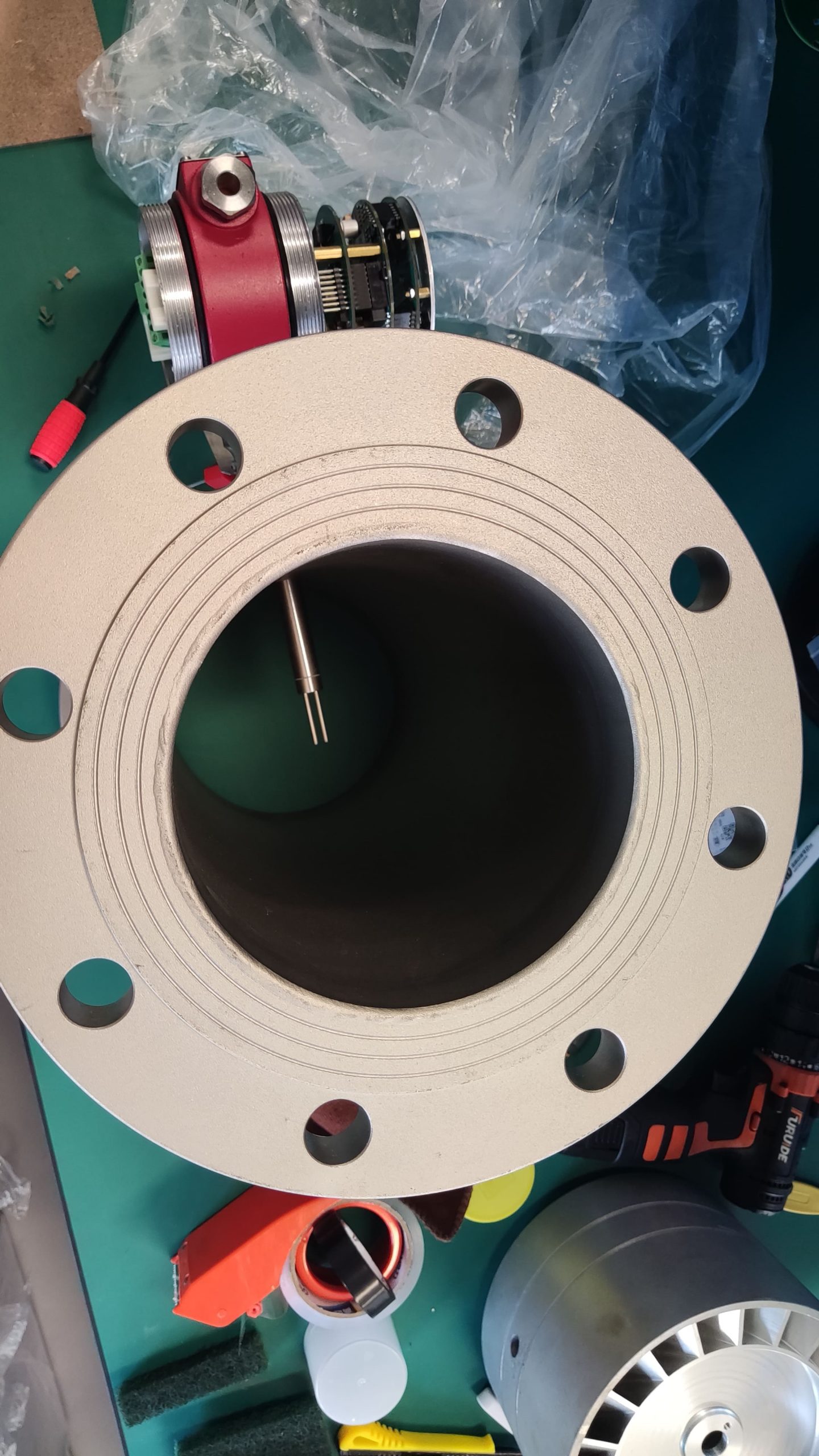

Then let’s talk about the measurement principle of the thermal gas mass flowmeter, he is based on the principle of constant temperature difference to work, when the instrument works, a sensor continuously measures the medium temperature T1; The other sensor is self-heated to a temperature higher than the medium temperature T2, which is used to sense the flow rate of the flow body, called the velocity sensor. The temperature ΔT=T2-T1, T2>T1, when there is a fluid flowing, because the gas molecules collide with the sensor and take away the heat of T2, so that the temperature of T2 drops, if the ΔT remains unchanged, it is necessary to increase the power supply current of T2, the gas flow speed is hot, the more heat is taken away.

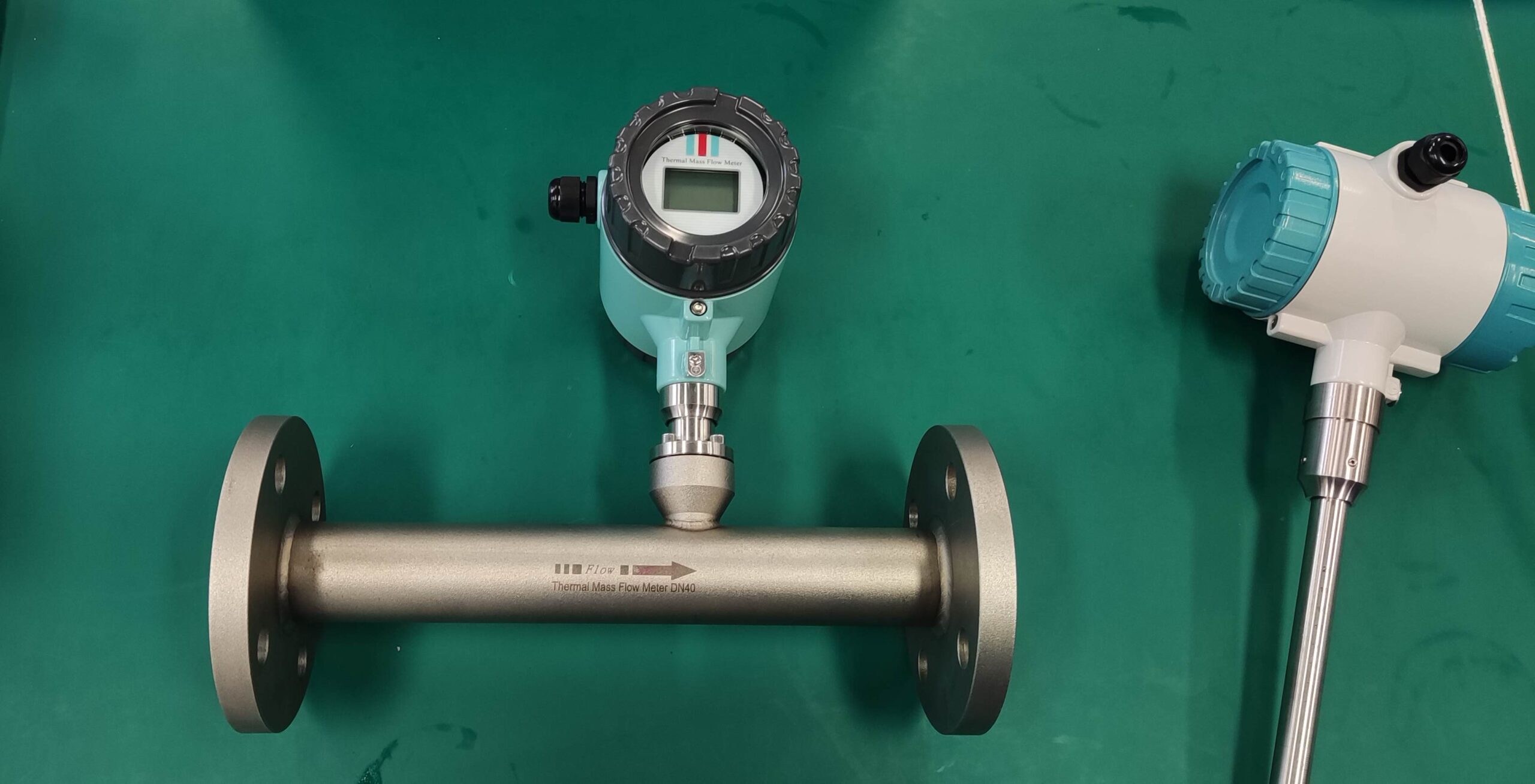

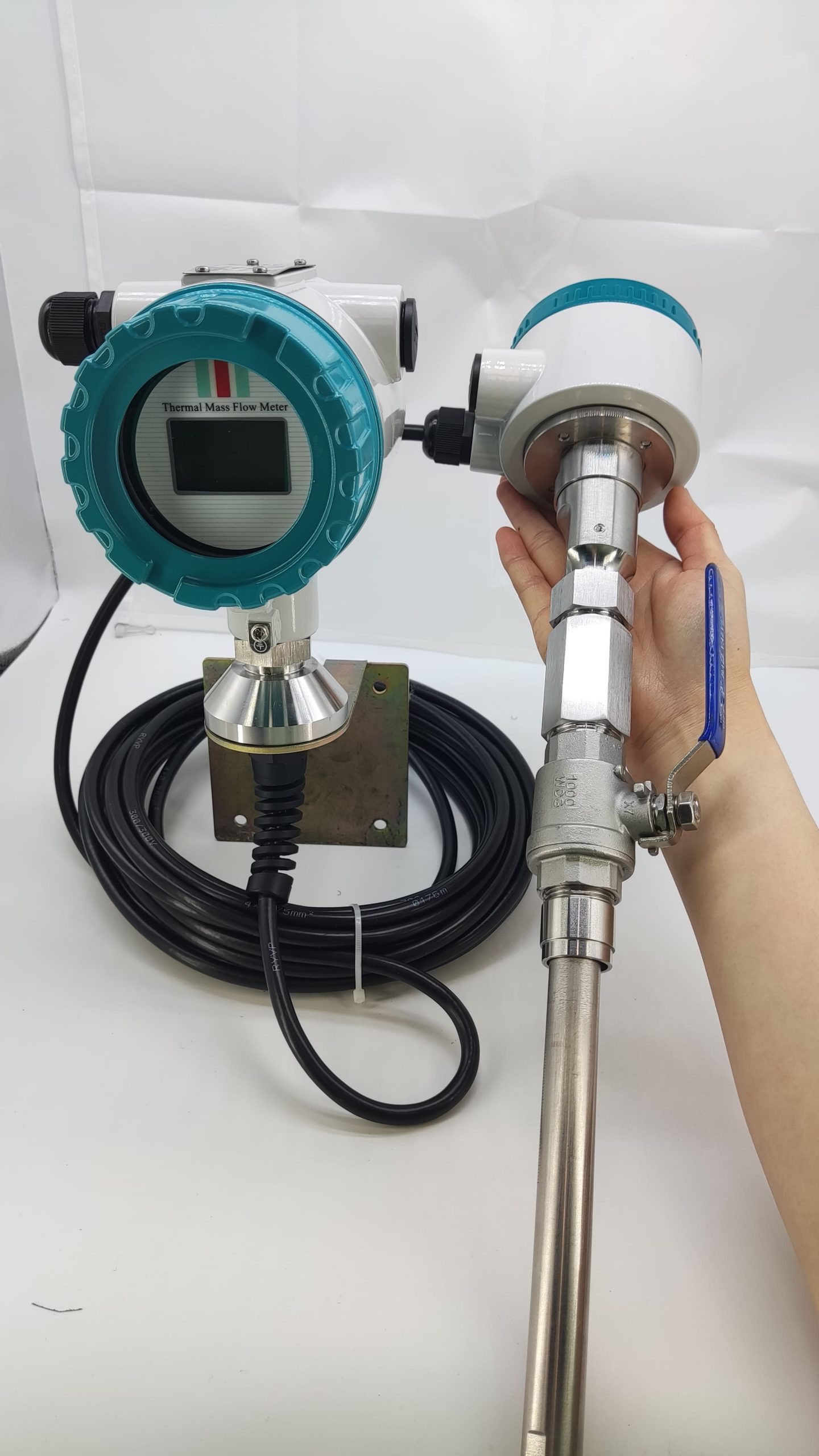

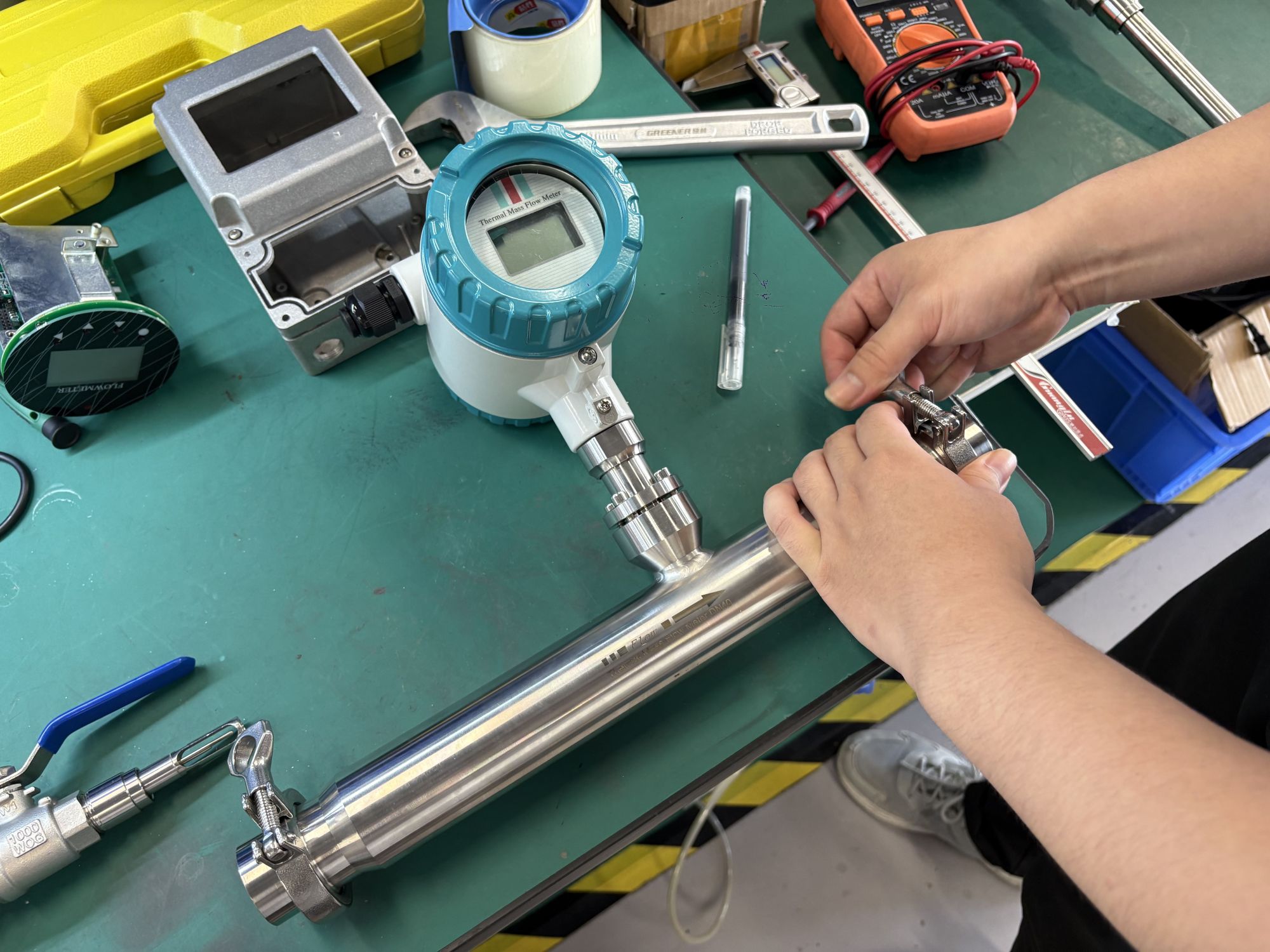

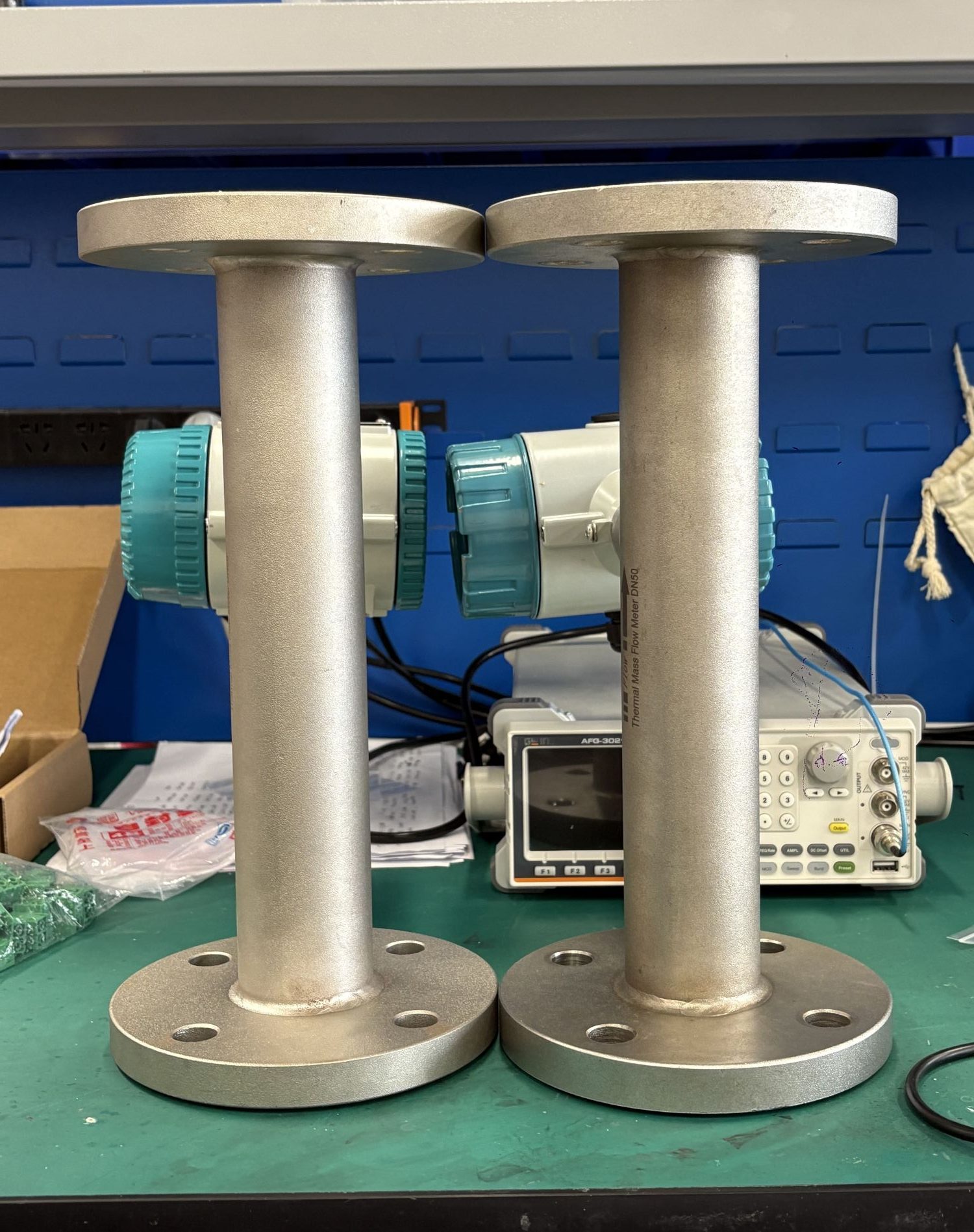

Finally, let’s talk about the installation problem, the installation of the thermal gas mass flowmeter is very simple, there are two installation methods: plug-in type and pipe type. Plug-in installation is simple and convenient, weld a base with external threads on the outer wall of the pipeline, install a 1-inch stainless steel ball valve on the base, and then use a special tool to drill a hole with a diameter of 22mm, remove the special tool after the hole is completed, and finally install the sensor on the valve and insert the sensor into the center of the tube.

Hot gas mass flowmeter has high precision, wide range, wear resistance, shock resistance, corrosion resistance, easy installation and use, maintenance-free is a good gas flowmeter.