Application of vortex flow meter in biogas measurement

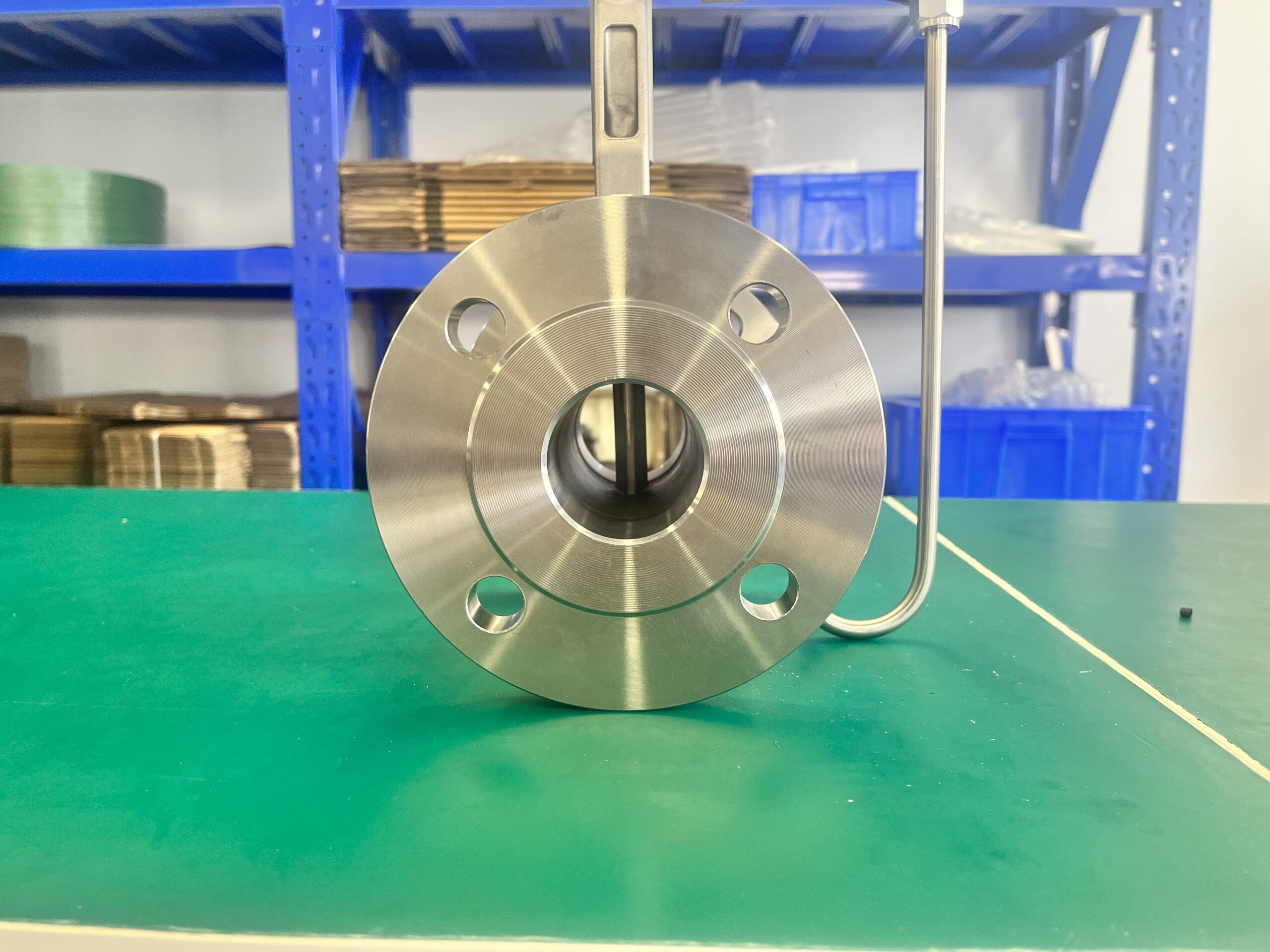

Vortex flowmeter is based on the Karman vortex street principle, which is mainly performed by setting a non-streamlined vortex generator (resistance fluid) in the flowing fluid, and alternately producing two columns of regular vortices from both sides of the vortex generator.

Vortex flowmeter is based on the Karman vortex street principle, which is mainly performed by setting a non-streamlined vortex generator (resistance fluid) in the flowing fluid, and alternately producing two columns of regular vortices from both sides of the vortex generator. Widely used in petroleum, chemical industry, metallurgy, heat, textile, paper and other industries for superheated steam, saturated steam, compressed air and general gases (oxygen, nitrogen, hydrogen, natural gas, gas, etc.), water and liquid (such as: water, gasoline, alcohol, benzene, etc.) measurement and control.

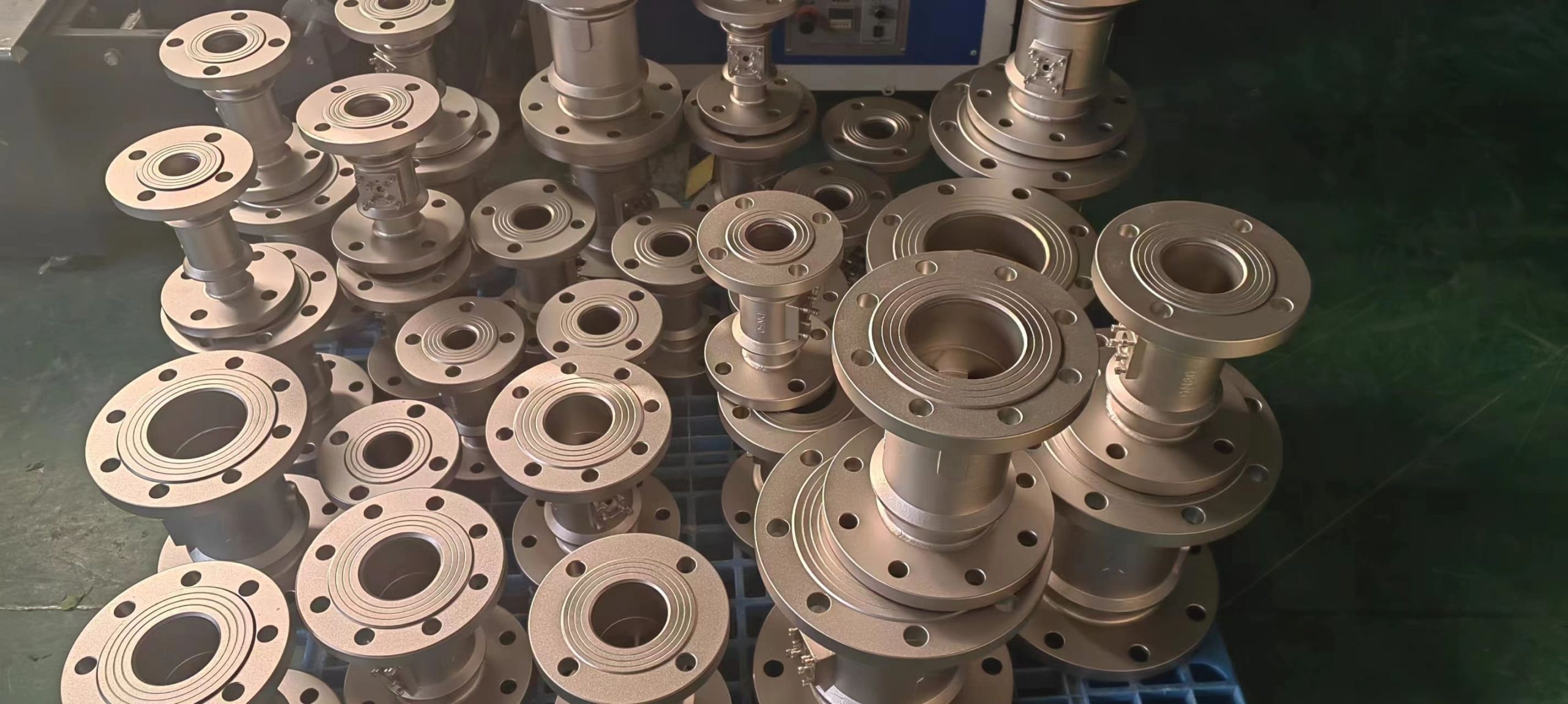

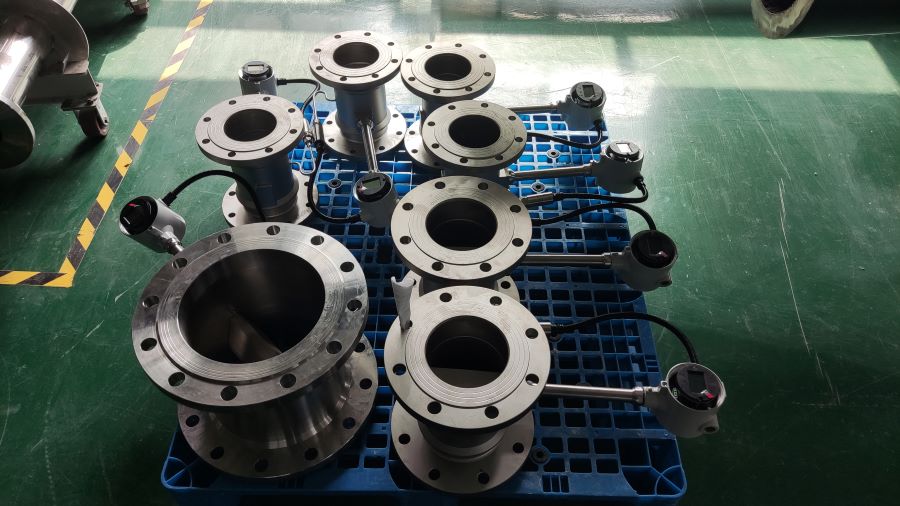

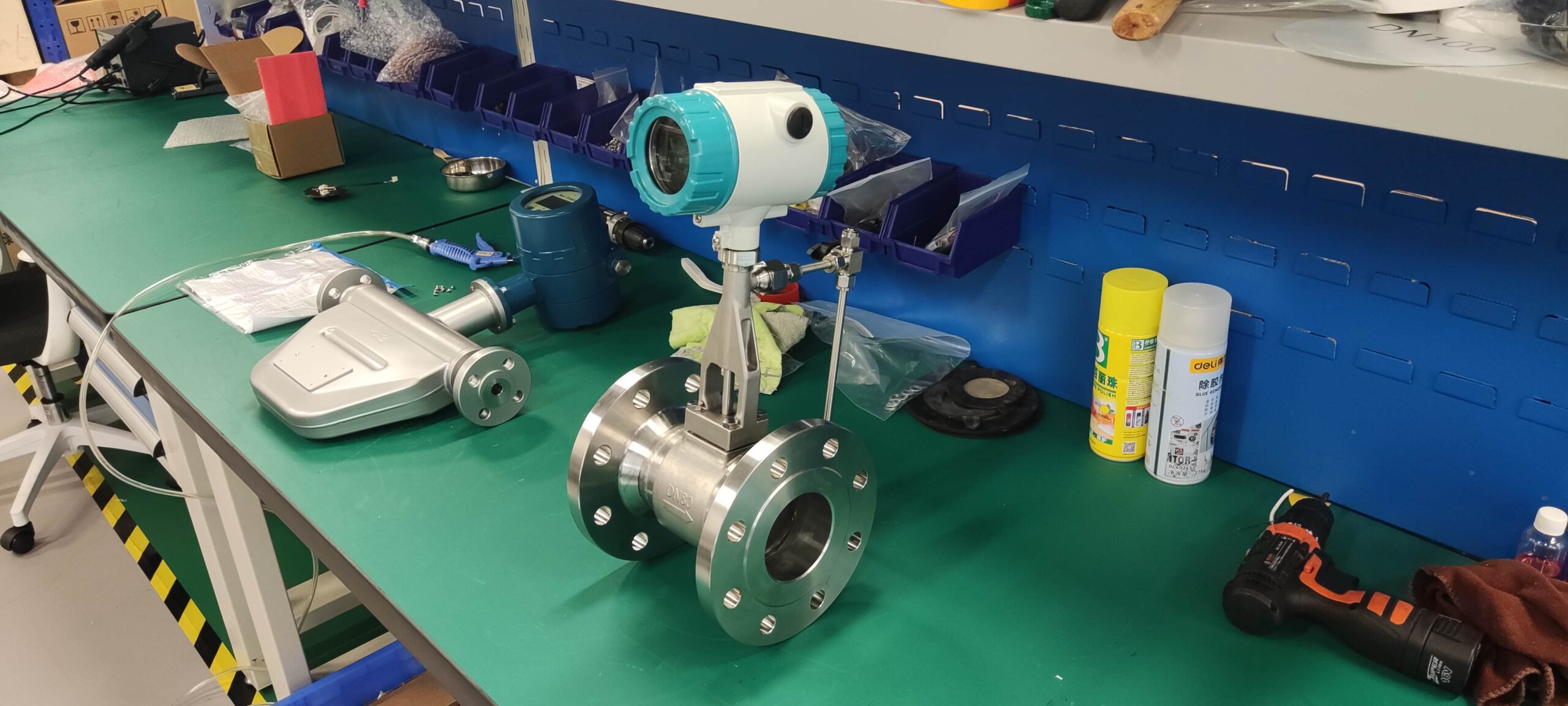

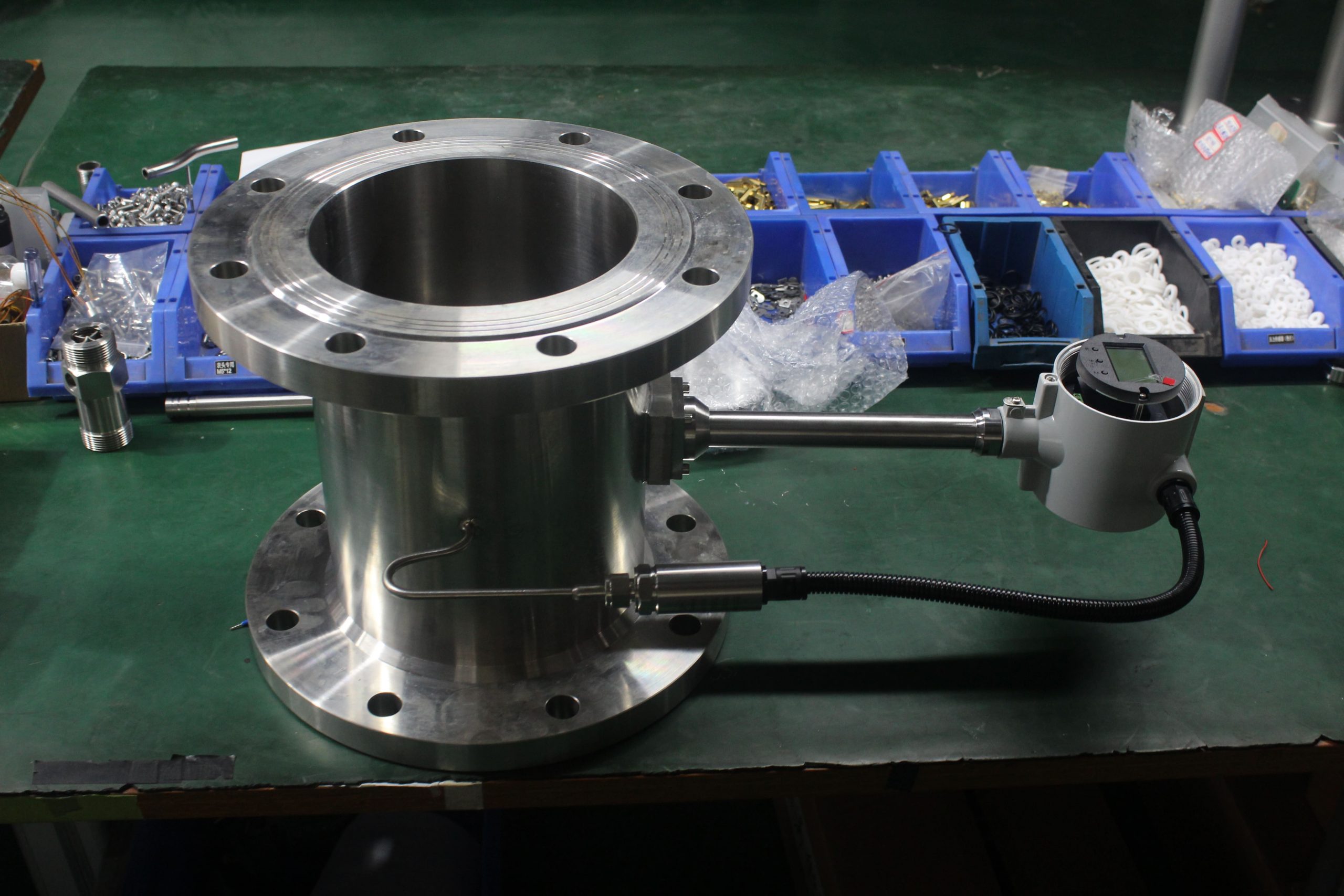

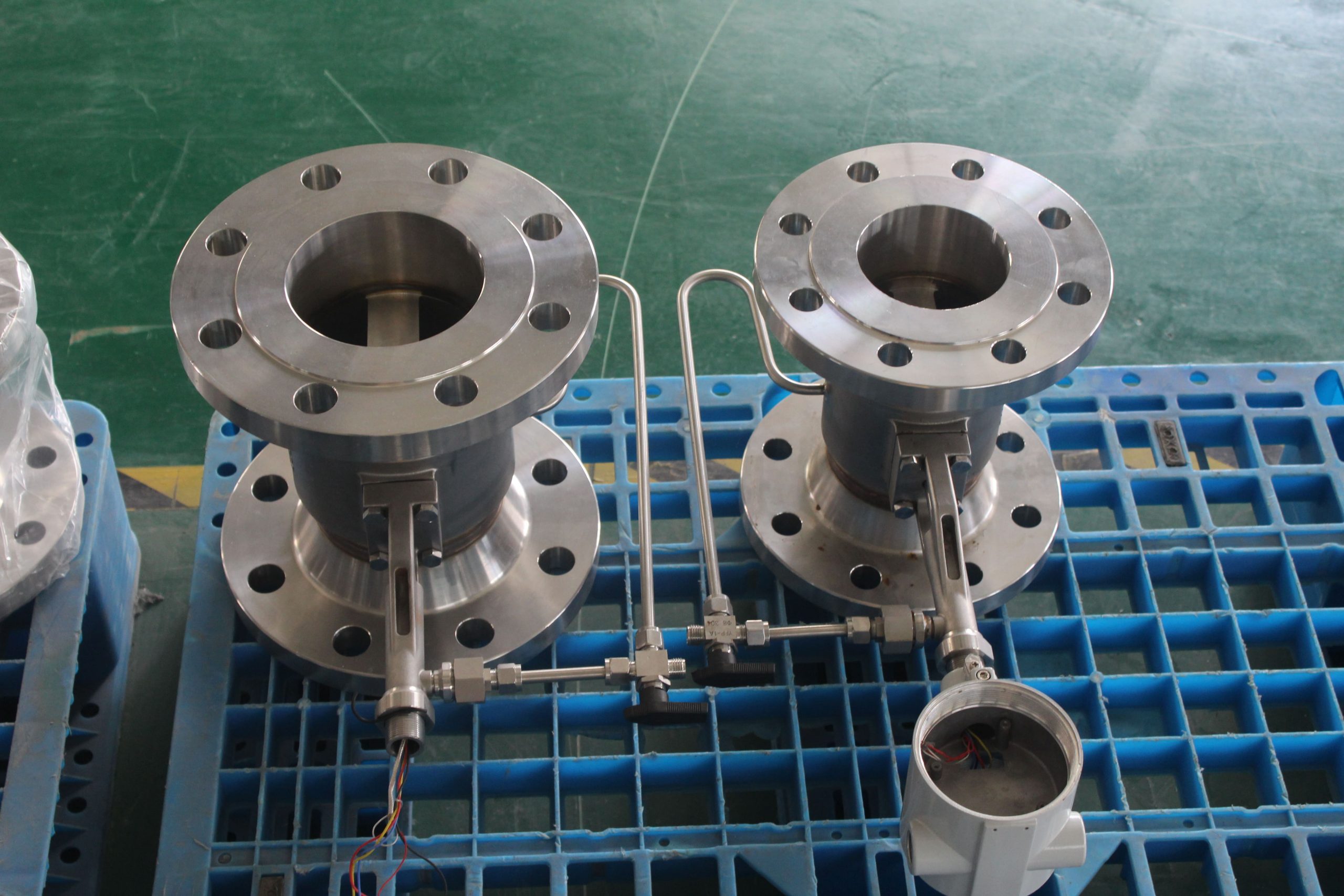

Usually, the flow rate of biogas pipelines is small, and it is generally measured by reducing the diameter. We can choose flange type and flange type 2 structural forms, selection must be selected to understand the small flow of biogas, common flow and large flow. Most biogas measuring sites do not have a power source, so we can choose a battery-powered vortex flowmeter. If the user needs to lead the display of the meter to the room, the integrated vortex flowmeter can be used to lead the output signal to the flow integrator installed in the room through the cable. The vortex flowmeter can display the instantaneous flow rate of biogas and the cumulative flow rate.

When installing the flowmeter in the measurement of biogas, if the valve is installed near the upstream of the installation point, and the valve is constantly switched on and off, the service life of the sensor is greatly affected, and it is very easy to cause damage to the sensor, and the sensor should be avoided as far as possible on a very long overhead pipeline. Because the sag of the sensor is very easy to cause the seal between the sensor and the flange to leak, if it is necessary to install, it is necessary to set the pipe fastening device at the upstream and downstream 2D of the sensor.

To ensure full functionality, the flow pattern at the entrance should be undisturbed. The length of the upstream straight pipe section shall be approximately 15 times the meter diameter (D), and the length of the downstream straight pipe section shall be approximately 5 times the meter diameter (D). When the non-streamlined vortex sound is set in the fluid, two columns of regular vortices are produced alternately from both sides of the vortices, which is called Karman vortex street. In a certain flow range, the vortex separation frequency is proportional to the average flow rate in the pipeline, and the capacitor probe or piezoelectric probe (detector) is loaded into the vortex generator and the corresponding circuit is configured, that is, the capacitance detection vortex flowmeter or piezoelectric detection vortex flow sensor is formed.