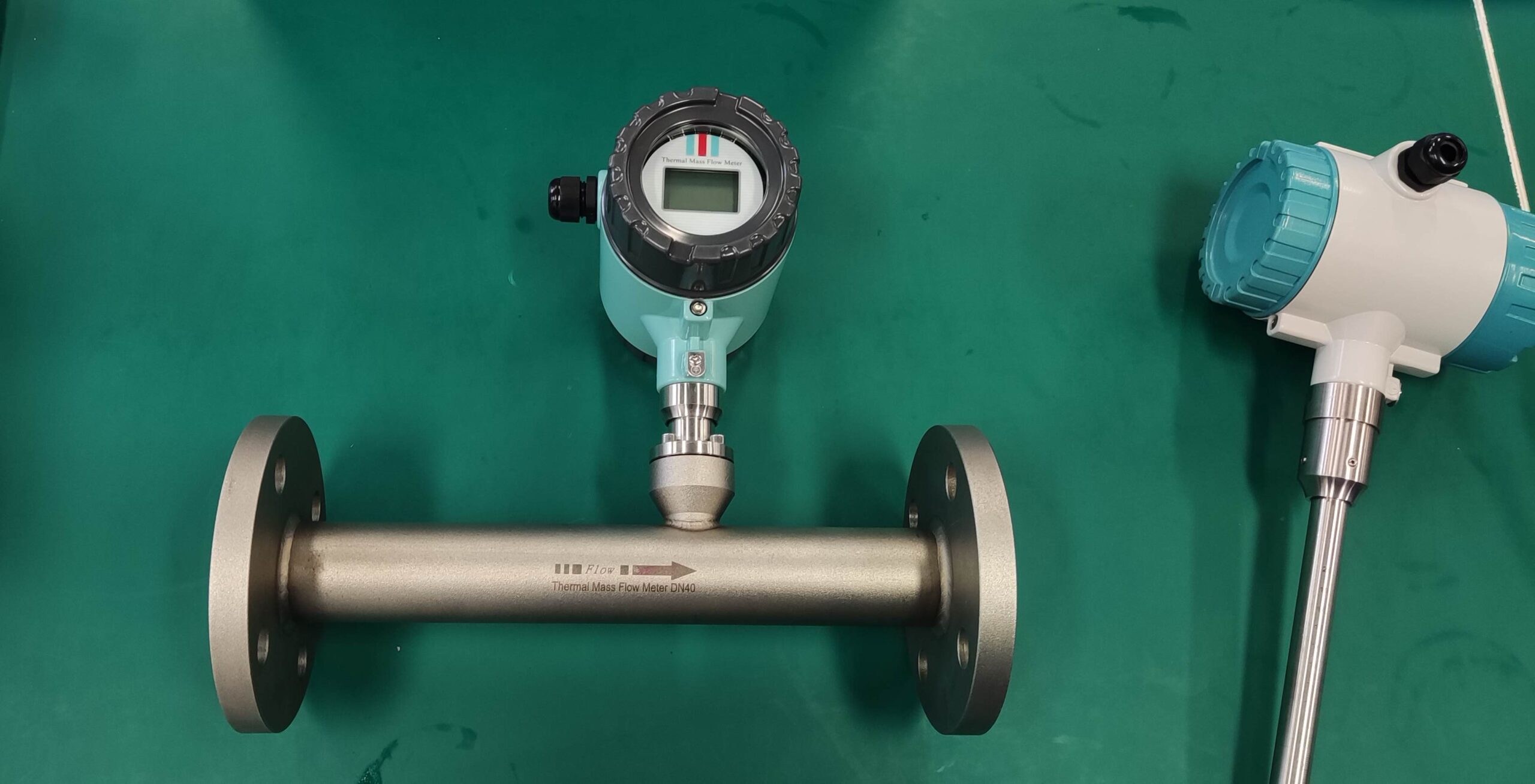

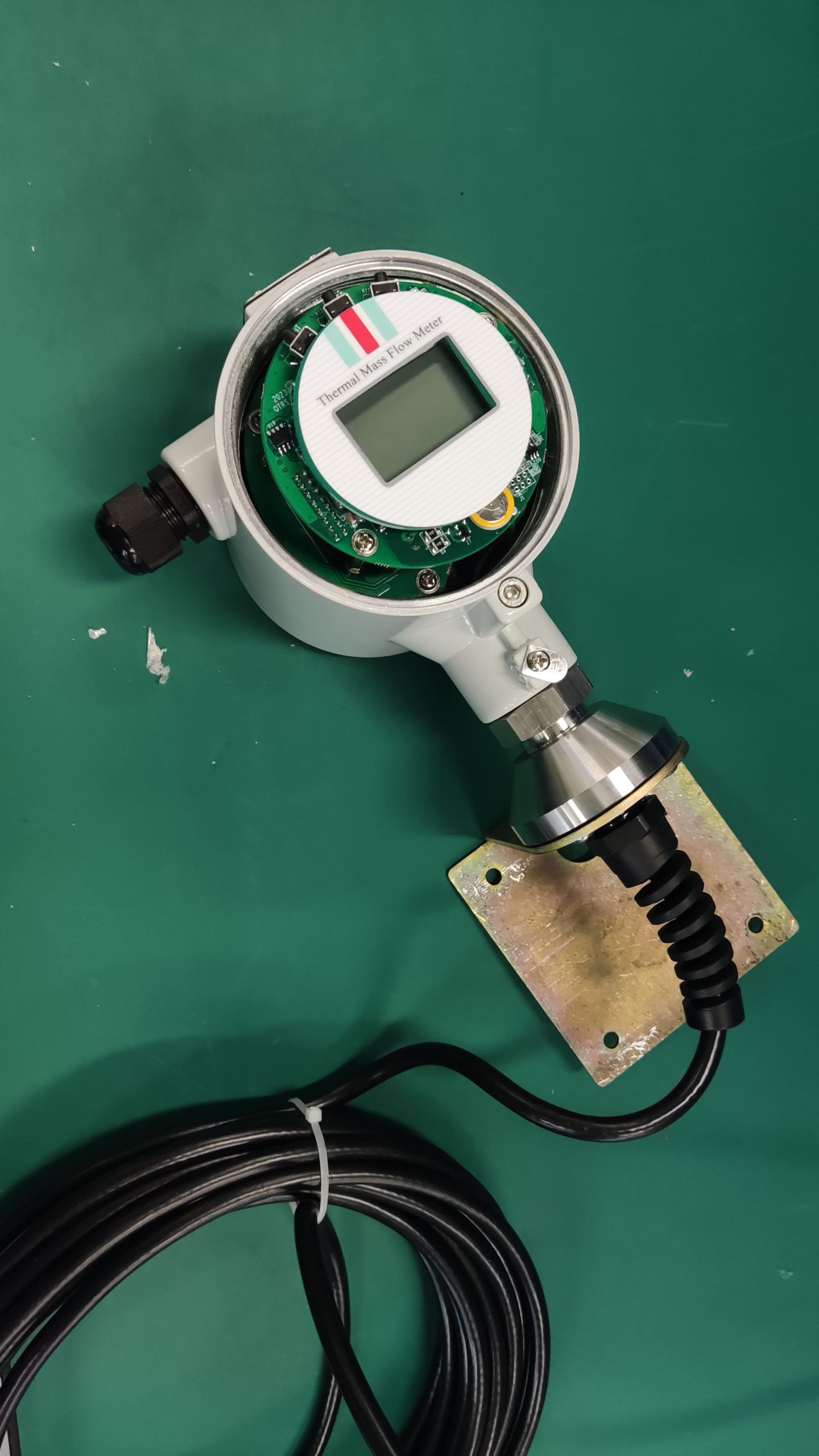

Application of thermal gas mass flowmeter in oxygen emission measurement

At present, oxygen generator in the production process will be affected by external influences, more and more enterprises for fine management, energy consumption, cost accounting and other requirements for the loss of this part of the oxygen measurement.

Due to the uncertainty of pressure and flow rate during oxygen release, it is difficult for traditional flowmeters to adapt to the measurement of oxygen release. In the actual production of the amount of oxygen release is restricted by the user, such as the iron industry in the iron smelting furnace oxygen enrichment is a large use of oxygen, if the blast furnace short-term furnace condition fluctuations need to reduce or stop the oxygen enrichment, and this with the steelmaking system due to the lack of hot metal can not continue to produce, coupled with the oxygen production capacity of the oxygen generator limitations, often cause a large amount of oxygen release. In this case, the oxygen gap of the oxygen generator is too large, and the oxygen generator is restarted for too long, and the oxygen can not be supplied in a short time, and the oxygen has to be released in order to maintain continuous production. The uncertainty of oxygen demand of external oxygen units leads to the uncertainty of oxygen emission. Therefore, the uncertainty and rapid change of oxygen emission is a major feature of oxygen emission. In the actual production, the measurement of the amount of oxygen release is restricted by the oxygen process production during oxygen release, and has the following special requirements:

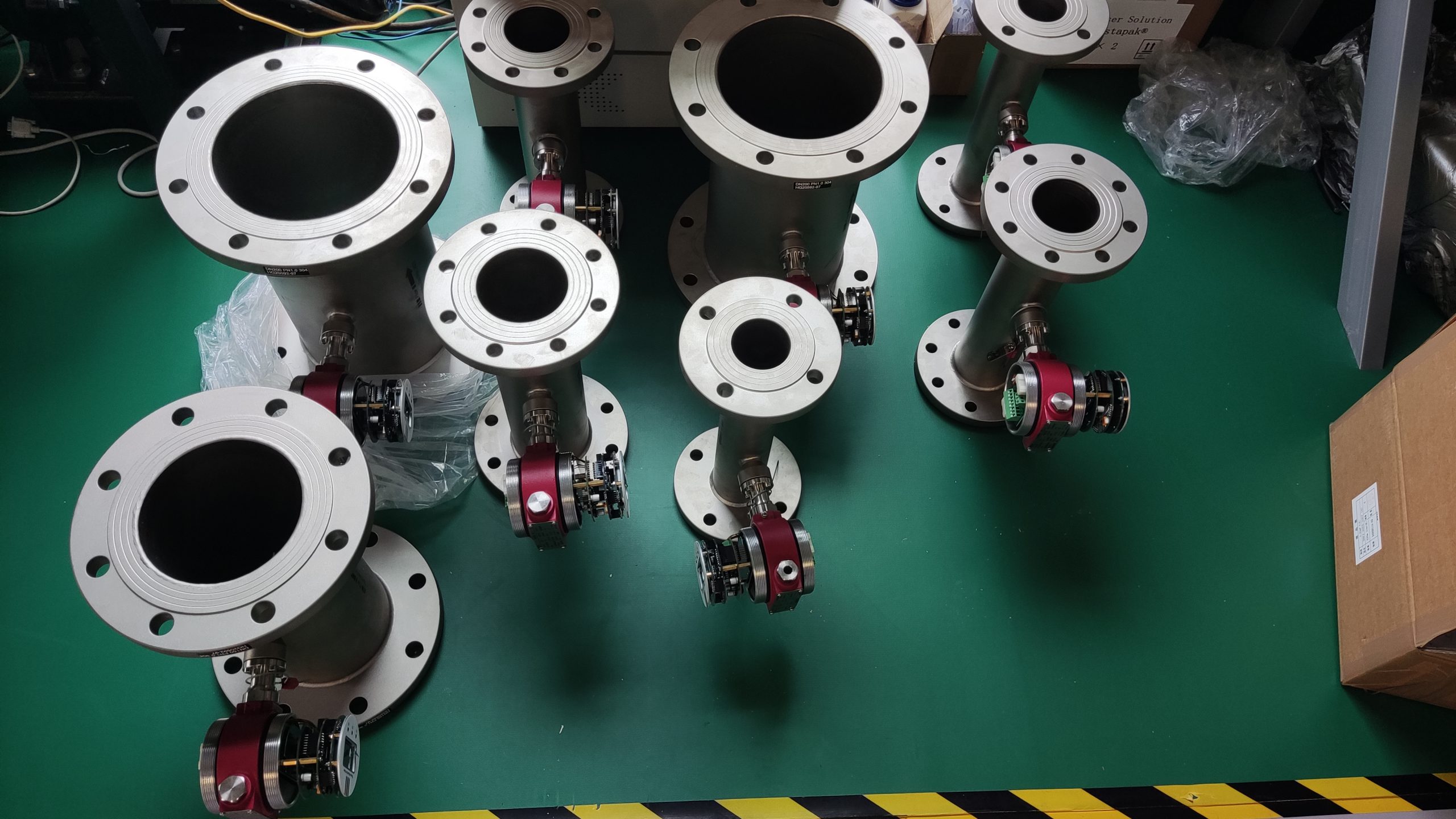

1. Due to the uncertainty of the actual amount of oxygen release, it usually fluctuates within a large range with the change of pipe network pressure and changes frequently. The characteristics of the uncertainty and large change of the oxygen emission require the flow meter to have a large range ratio, and the measurement accuracy needs to be ensured in the entire range, whether it is at high flow or low flow.

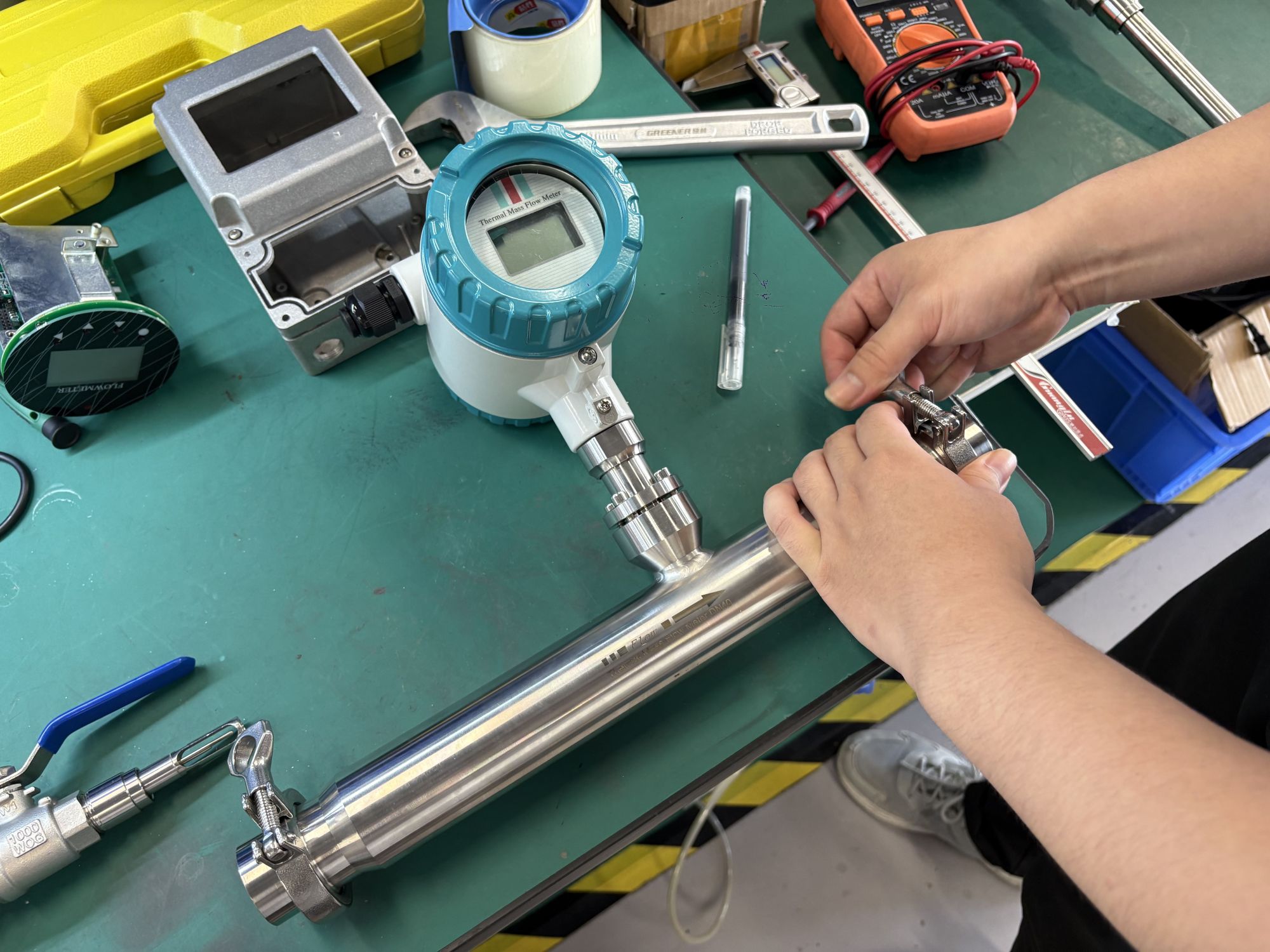

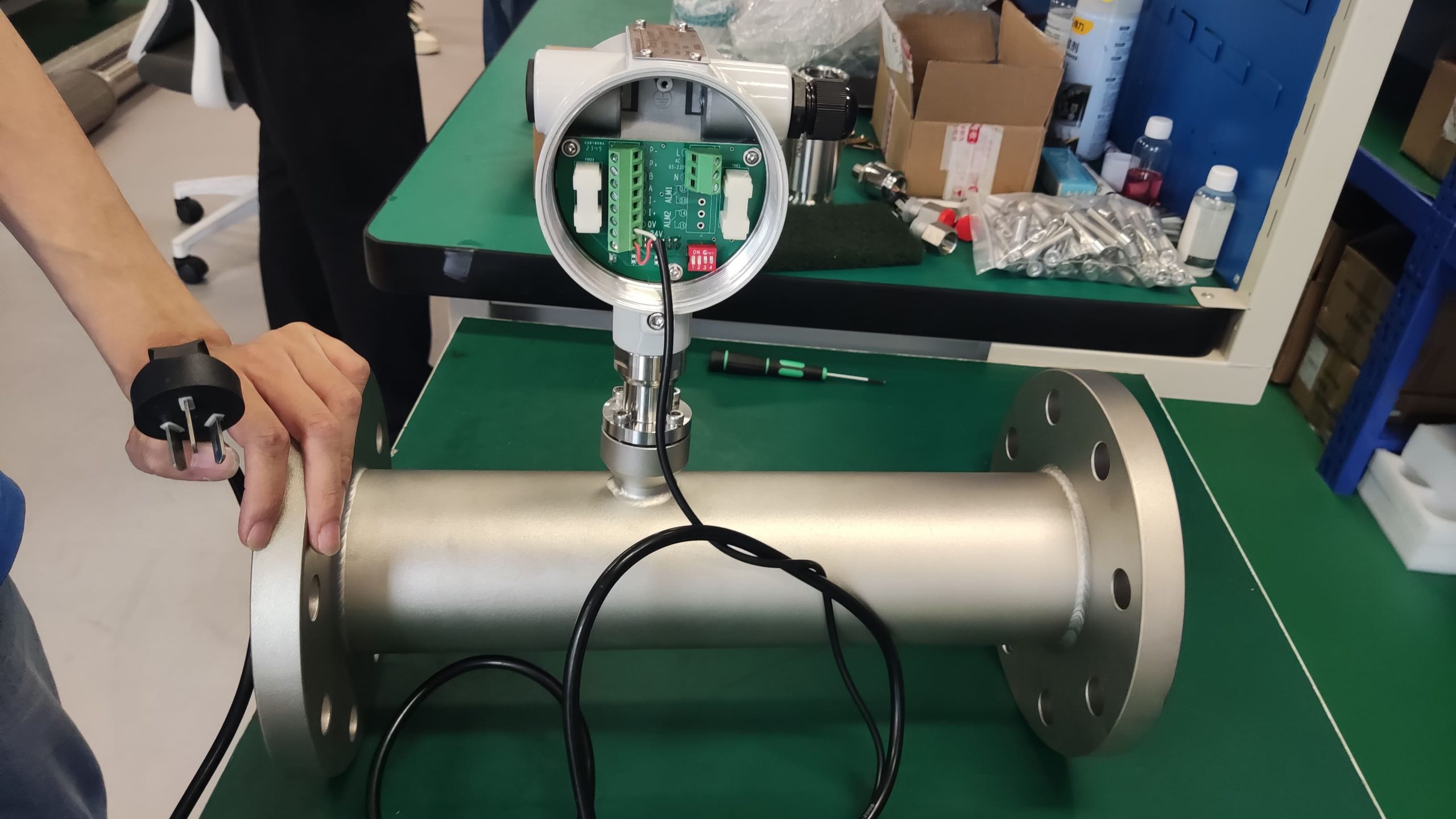

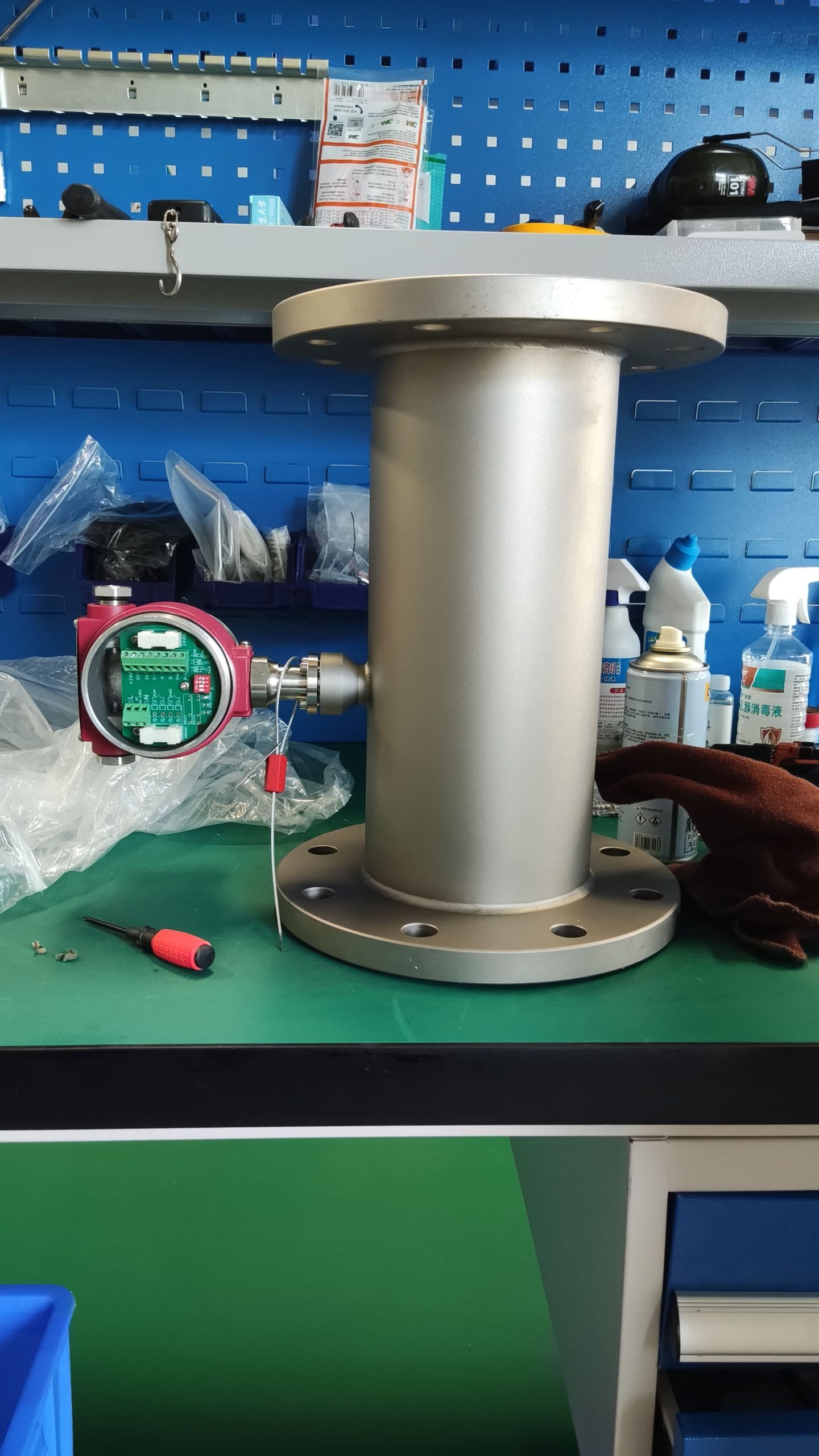

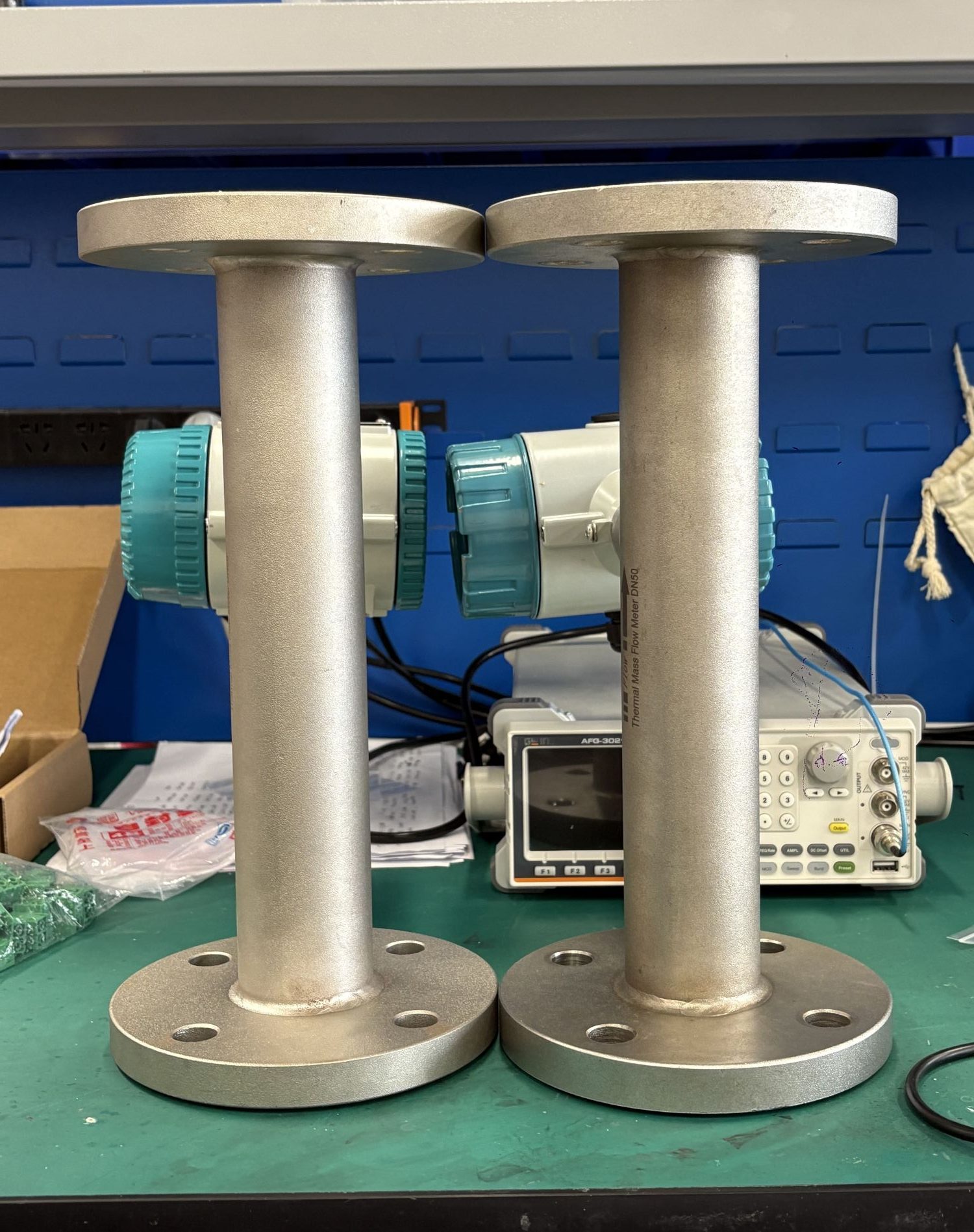

2. Oxygen discharge flowmeter has high requirements for installation, in order to avoid metal debris burning and exploding in oxygen after installation, the flowmeter is required to reduce installation debris as much as possible;

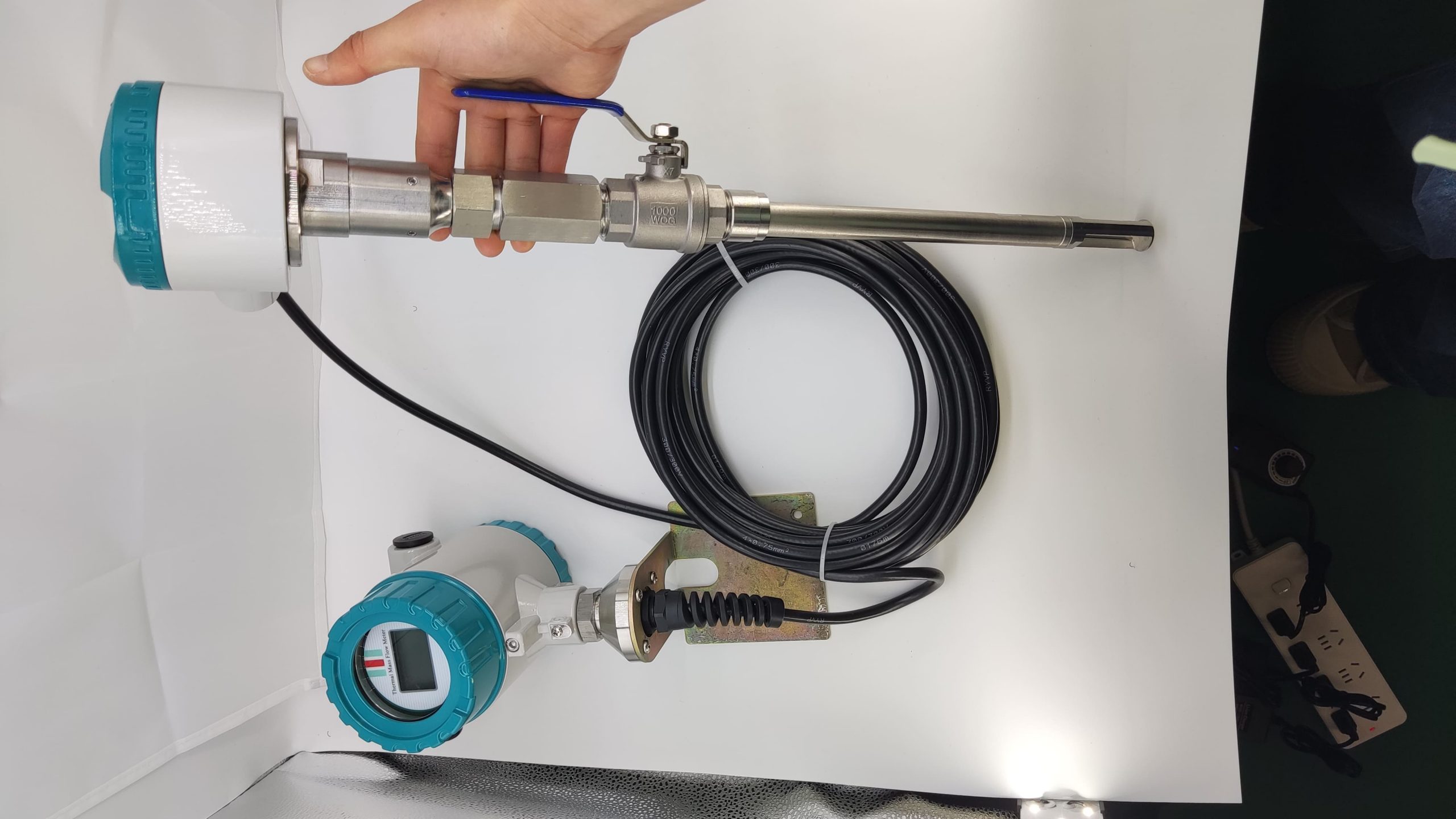

3. The oxygen discharge flowmeter is installed on the discharge pipe. In case of emergency, the oxygen discharge pipe is the best outlet for the oxygen generator to quickly discharge oxygen, so the pressure loss of the flow rate is required to be as small as possible to reduce the obstruction of the flow meter to the oxygen discharge;

4. During the oxygen release process, the flow rate and pressure change dramatically, and the oxygen flow rate changes dramatically, so the flow meter is required to have sufficient strength to ensure safety. If the flow meter breaks during the discharge process, the consequences will be unimaginable.

5. Most of the oxygen discharge is installed after transformation, subject to more limiting factors such as site and pipeline, therefore, the oxygen discharge flowmeter is required to be easy to install, and the flowmeter with low requirements for the straight pipe section is required. At the same time, affected by the installation position of the release valve, the oxygen release flowmeter should be able to meet the ability to adapt to different working states before and after the release valve. The thermal gas mass flowmeter provides a new way for the measurement of oxygen emission.