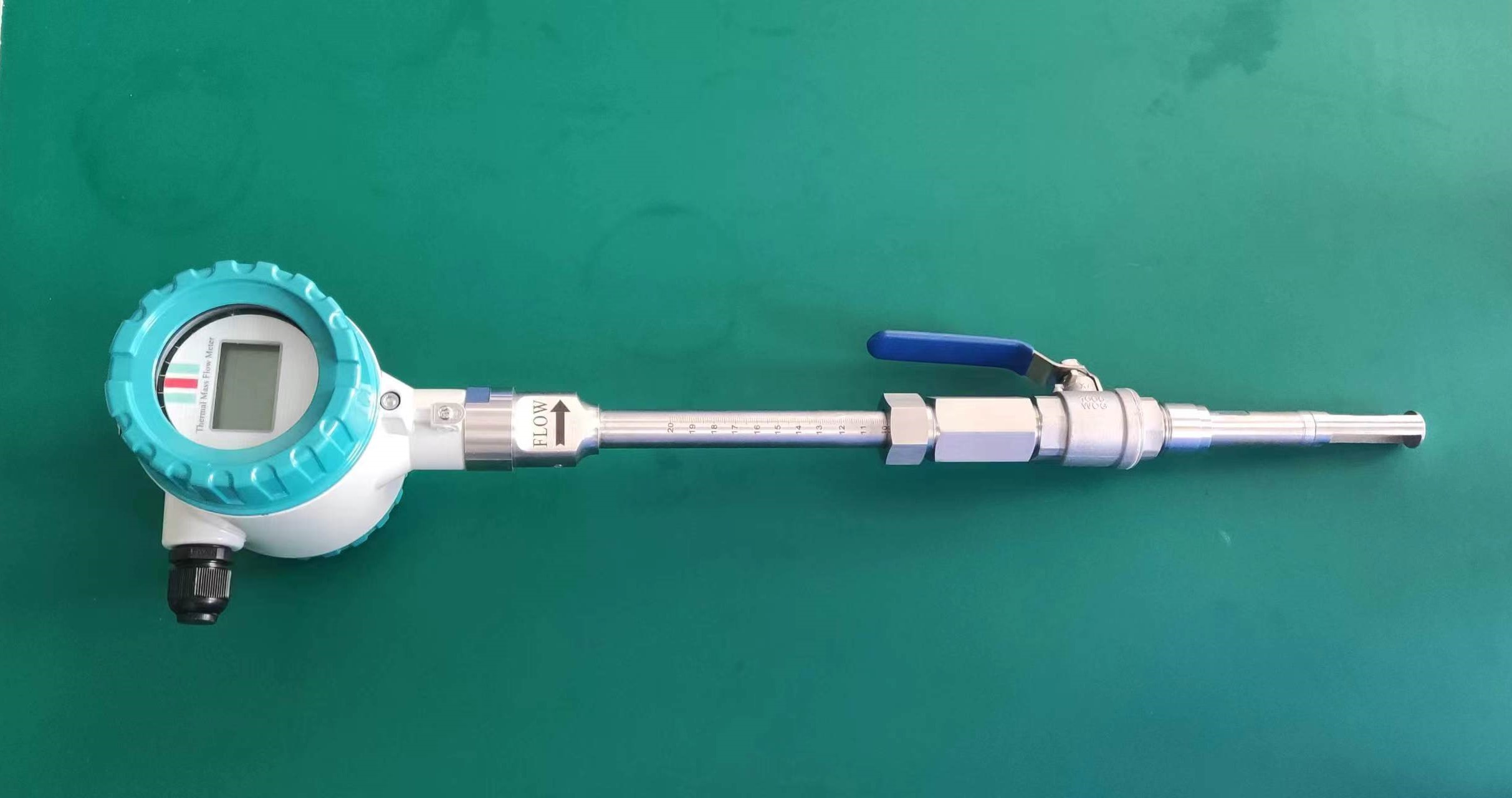

Application of thermal gas mass flow meter in pipeline transportation of natural gas

Although the thermal gas mass flowmeter has many advantages in this respect, it can not be used for large pipe runoff measurement, pressure loss is relatively large, and the price is more expensive, which limits its measurement application in natural gas long distance pipeline.

Although the thermal gas mass flowmeter has many advantages in this respect, it can not be used for large pipe runoff measurement, pressure loss is relatively large, and the price is more expensive, which limits its measurement application in natural gas long distance pipeline. At present, the mainstream natural gas metering instruments in long-distance pipelines are ultrasonic flowmeters, turbine flowmeters and orifice flowmeters.

Orifice flowmeter because of its low accuracy, small range, large pressure loss, the straight pipe section before and after the flowmeter is also relatively long, occupies a large area, more components involved in the detection need to maintain more links and many other shortcomings. However, ultrasonic flowmeter has high accuracy, large range ratio, no pressure loss and energy saving; No moving parts, small maintenance, can save a lot of manpower and material resources. At present, ultrasonic flowmeter has gradually replaced the orifice flowmeter to become the ideal product for natural gas trade handover.

The application history of gas turbine flowmeter is relatively long, the technology is also relatively mature, and the current application in the international natural gas measurement field is also relatively common. However, the gas turbine flowmeter has high requirements for the cleanliness of the measured medium, because the impeller of the turbine flowmeter is easy to damage, so most of the filters are required to be installed before the flowmeter; And there are also high requirements on the operation. As a result, the amount of maintenance and repair of the turbine flowmeter in the later period is relatively large.

Although the ultrasonic flowmeter has many advantages, because the measurement principle of the ultrasonic flowmeter is the propagation time difference method, when the diameter of the ultrasonic flowmeter changes, the acoustic path of the acoustic wave propagation becomes shorter, and the propagation is applied correspondingly shorter, the propagation time difference will be difficult to get accurate measurement values, which makes the range ratio and accuracy of the small-caliber ultrasonic flowmeter will decline.

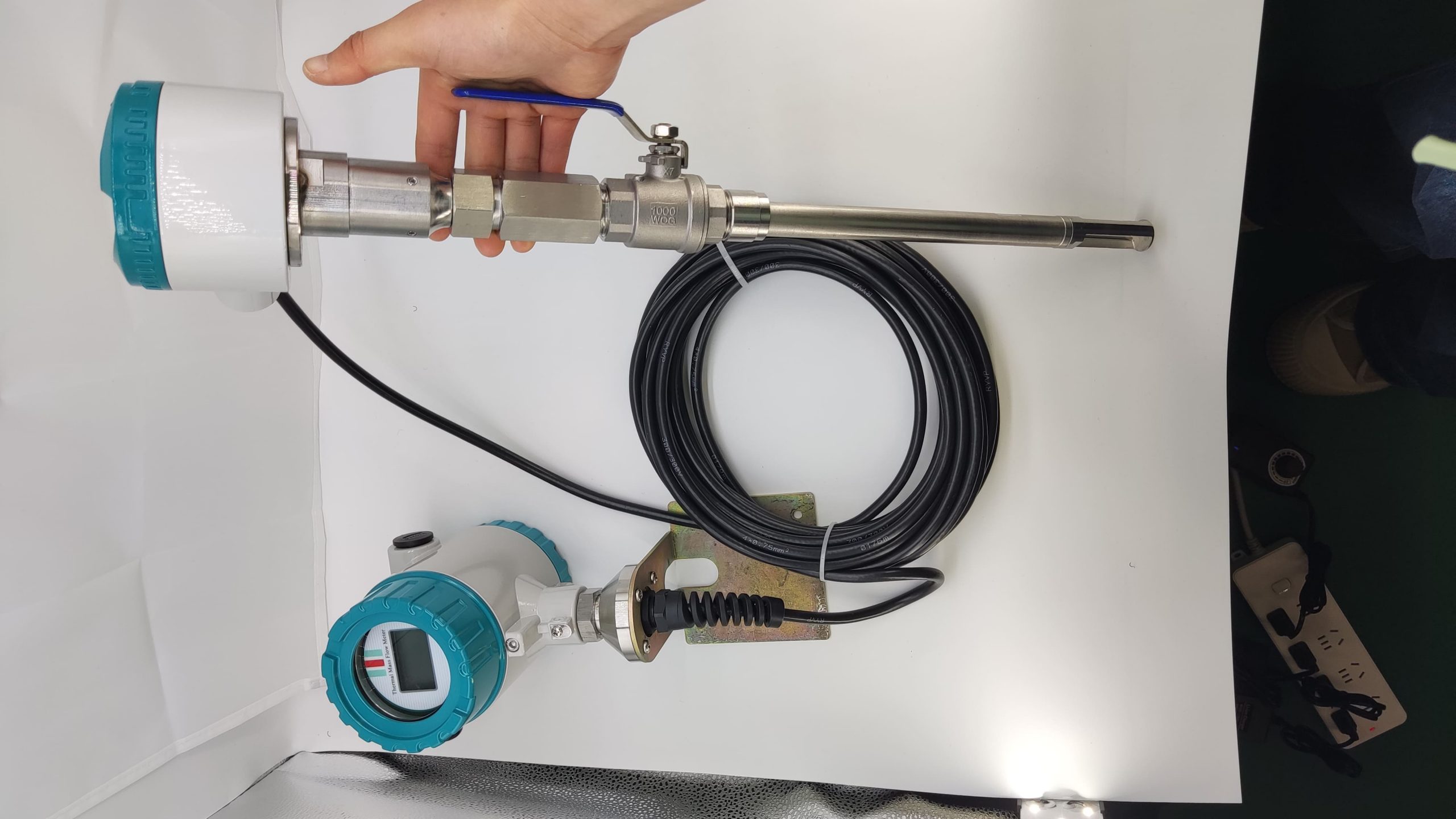

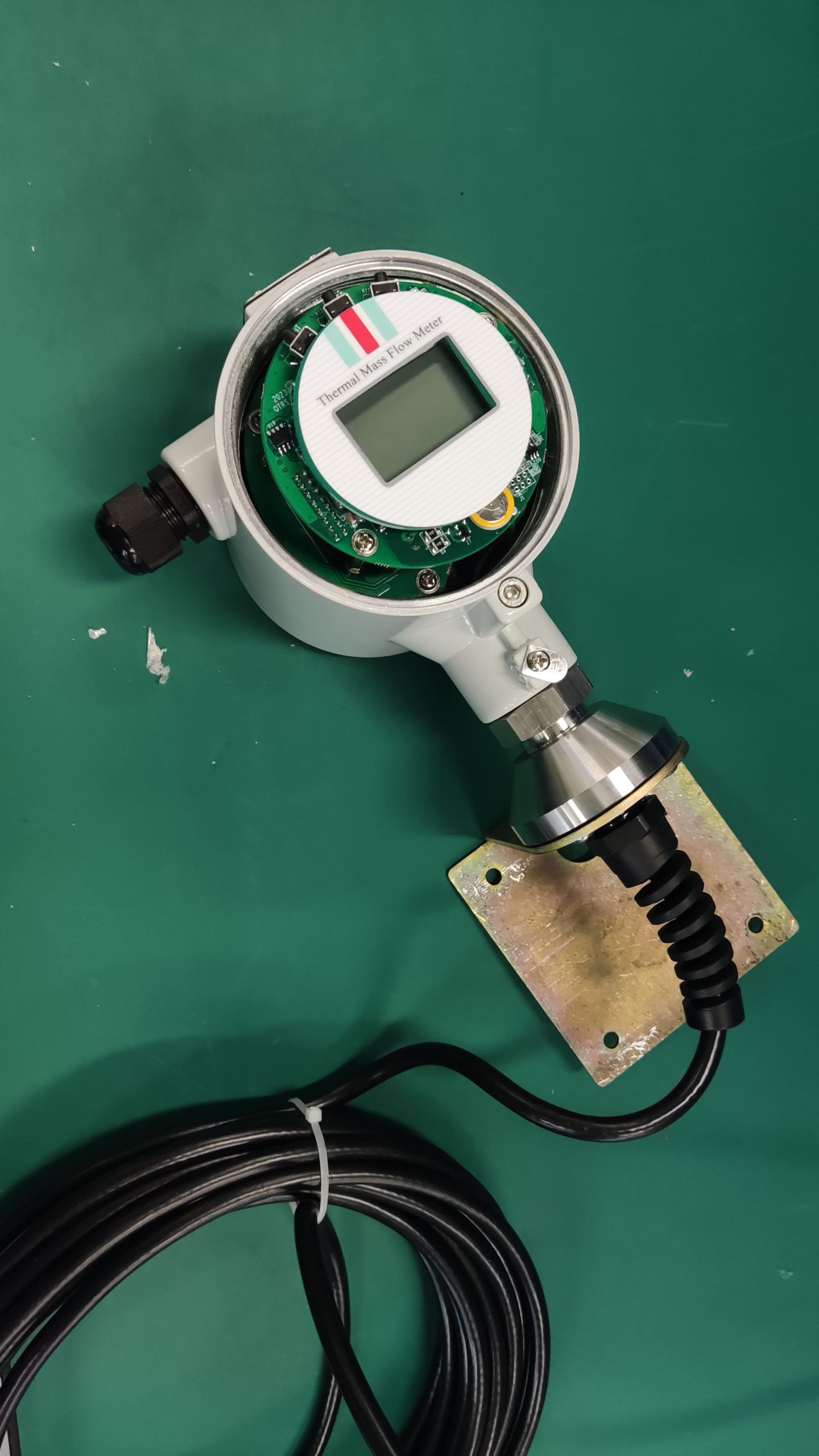

Therefore, in the pipeline natural gas measurement, the use space left for the mass flow meter is basically only small caliber, and some dirtier natural gas two cases, in these two cases, the mass flow meter can give full play to its advantages.