Analysis on the fault of electromagnetic flow meter caused by bubbles in the medium

There are two ways to produce bubble-like gas in liquid, which are inhaled gas from the outside or dissolved gas in the medium is transformed into a free bubble.

If there is a large bubble in the medium, the entire electrode is covered when the bubble passes through the electrode, so that the flow signal input loop is instantaneously open, so that the output signal will fluctuate. To determine the cause of this fluctuation, you can do so, cut off the circuit current of the magnetic field, and if the flowmeter is still displayed after cutting off and is still in a fluctuating state, it is proved that the existence of bubbles in the medium will cause fluctuations in the electromagnetic flowmeter. Using a pointer multimeter to measure the electrode resistance of the electromagnetic flowmeter, it will be found that the loop resistance of the electromagnetic flowmeter electrode is higher than the normal resistance value.

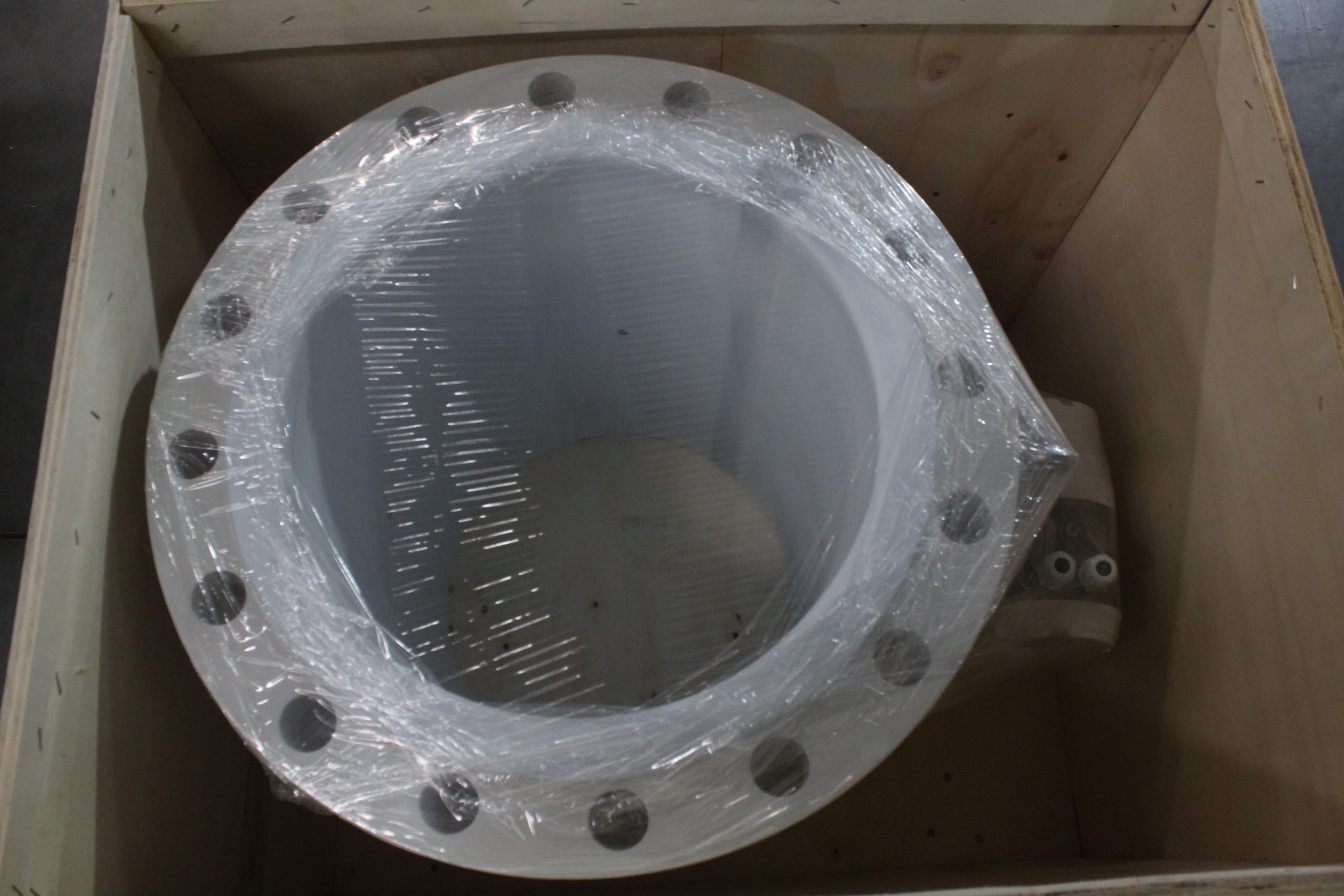

If the air enters the measured medium due to the installation position of the electromagnetic flowmeter, if the gas is stored due to the installation of the electromagnetic flowmeter at the high point of the pipe system, or the flow meter fluctuations caused by external air inhalation, the installation position of the electromagnetic flowmeter needs to be replaced and installed at the lowest point of the pipeline, or the U-shaped pipe installation is used. However, in some cases, due to the large diameter of the electromagnetic flowmeter or the installation position is not easy to change, it is possible to install the collecting bag and exhaust valve in the upstream of the flowmeter to solve this situation.

-.jpg)