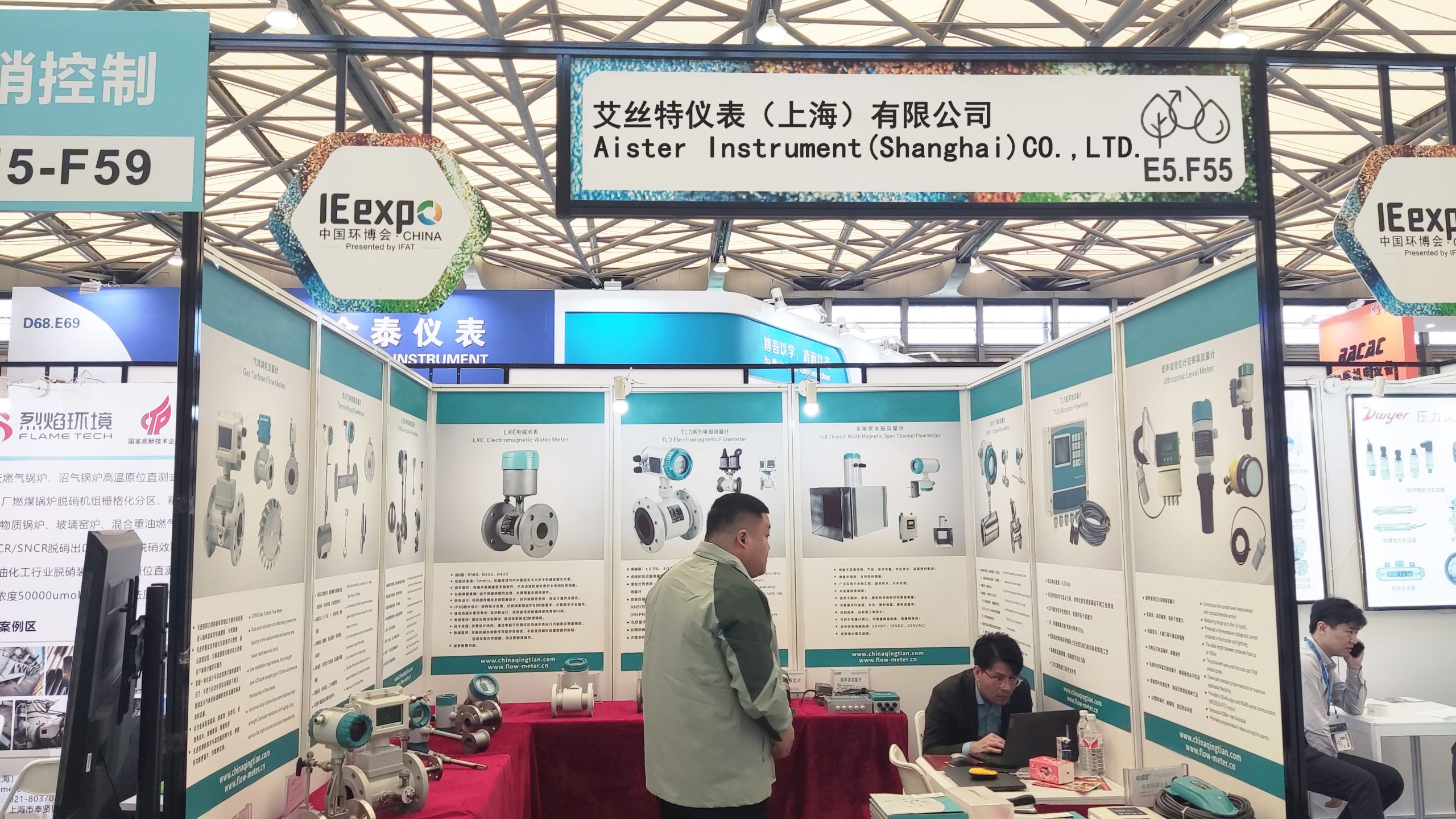

Aister Instrument All In-depth Study Of Electromagnetic Flow Meter

Electromagnetic flowmeters, also known as magmeters, are devices used to measure the flow rate of conductive liquids. They operate on the principle of Faraday’s Law of Electromagnetic Induction. Here’s how they work:

Magnetic Field Generation: A magnetic field is generated by passing a direct current (DC) through coils located within the flowmeter. These coils are typically wound around the flow tube through which the liquid flows.

Flow Measurement: When a conductive liquid flows through the flow tube, it cuts across the magnetic field lines. According to Faraday’s Law of Electromagnetic Induction, when a conductor moves through a magnetic field, an electromotive force (EMF) is induced in the conductor. In the case of the flowmeter, the conductive liquid acts as the moving conductor.

Induced Voltage Measurement: Electrodes are placed on opposite sides of the flow tube to measure the voltage generated by the movement of the conductive liquid through the magnetic field. This induced voltage is directly proportional to the flow rate of the liquid.

Output and Signal Processing: The induced voltage signal is then processed by the flowmeter’s electronics to determine the flow rate. This signal is typically amplified and converted into a linear output signal that can be displayed on a screen, recorded, or transmitted to a control system for further processing.

Compensation for Conductivity and Temperature: Electromagnetic flowmeters need to compensate for variations in the conductivity and temperature of the liquid to ensure accurate flow measurement. Modern electromagnetic flowmeters often have built-in algorithms to automatically adjust for these factors.

Application: Electromagnetic flowmeters are commonly used in industries such as water and wastewater treatment, chemical processing, food and beverage production, and pharmaceuticals, where accurate flow measurement of conductive liquids is essential.

Overall, electromagnetic flowmeters offer several advantages, including high accuracy, reliability, and the ability to measure the flow of corrosive and abrasive liquids without obstruction to the flow path.