Advantages of insertion electromagnetic flowmeters

Electromagnetic flowmeter for our life has a great positive significance, for large pipe diameter occasions, the insertion electromagnetic flowmeter has obvious advantages, then about the insertion electromagnetic flowmeter you do not fully understand?

1. Can the insertion electromagnetic flowmeter be battery-powered? If you can take 485 to communicate?

Aister: Sure. If there is no on-site, you can choose battery power, and can take 485. In addition to the power supply method is different, other functions and power supply are the same.

2. What are the advantages of the insertion electromagnetic flowmeter compared with the pipe type?

Aister: The insertion electromagnetic flowmeter has its own advantages in addition to the advantages of the general pipeline electromagnetic flowmeter. Such as: small size, light weight, easy installation and use, and lower production costs and installation costs. Therefore, if the pipe diameter is larger, the insertion connection is the better choice.

3. How to choose the insertion depth of the insertion electromagnetic flowmeter?

Aister: The specific insertion depth needs to be determined according to the diameter of the instrument, with DN400 as the dividing point, the following insertion 1/2, the above insertion 1/4, if you have other special requirements can contact the Aister instrument staff at any time, we are ready to answer you.

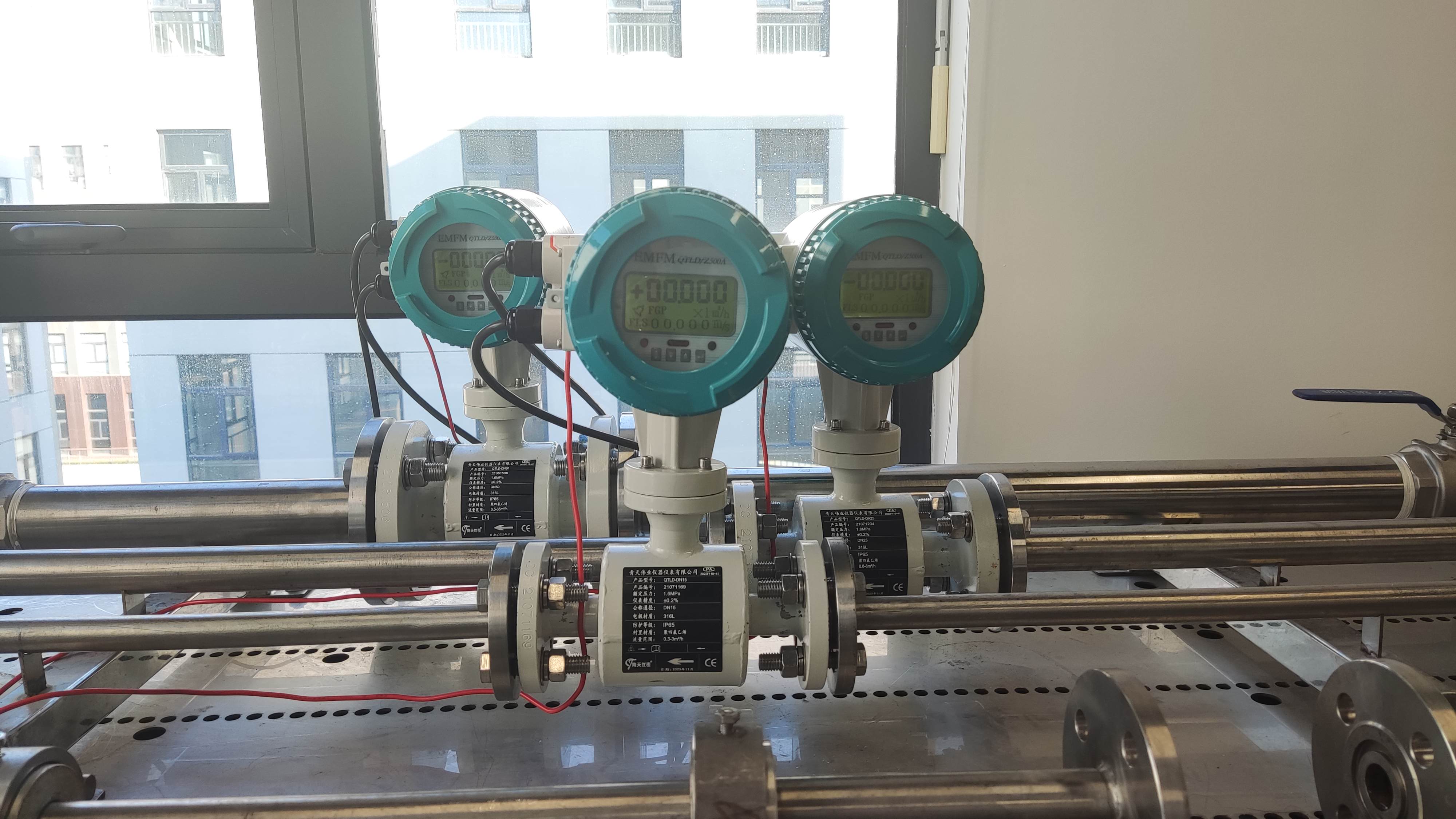

-.jpg)

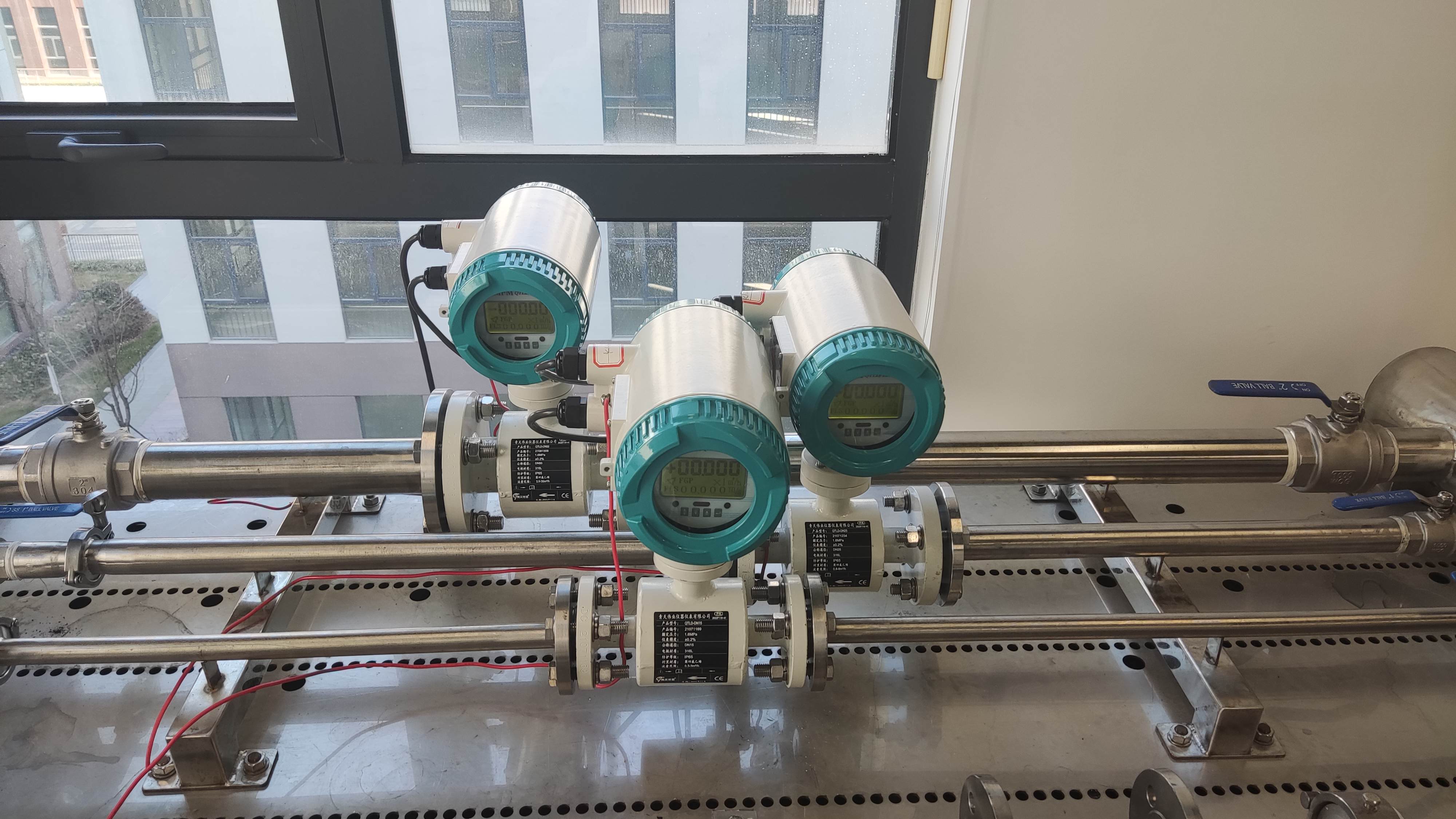

-.jpg)

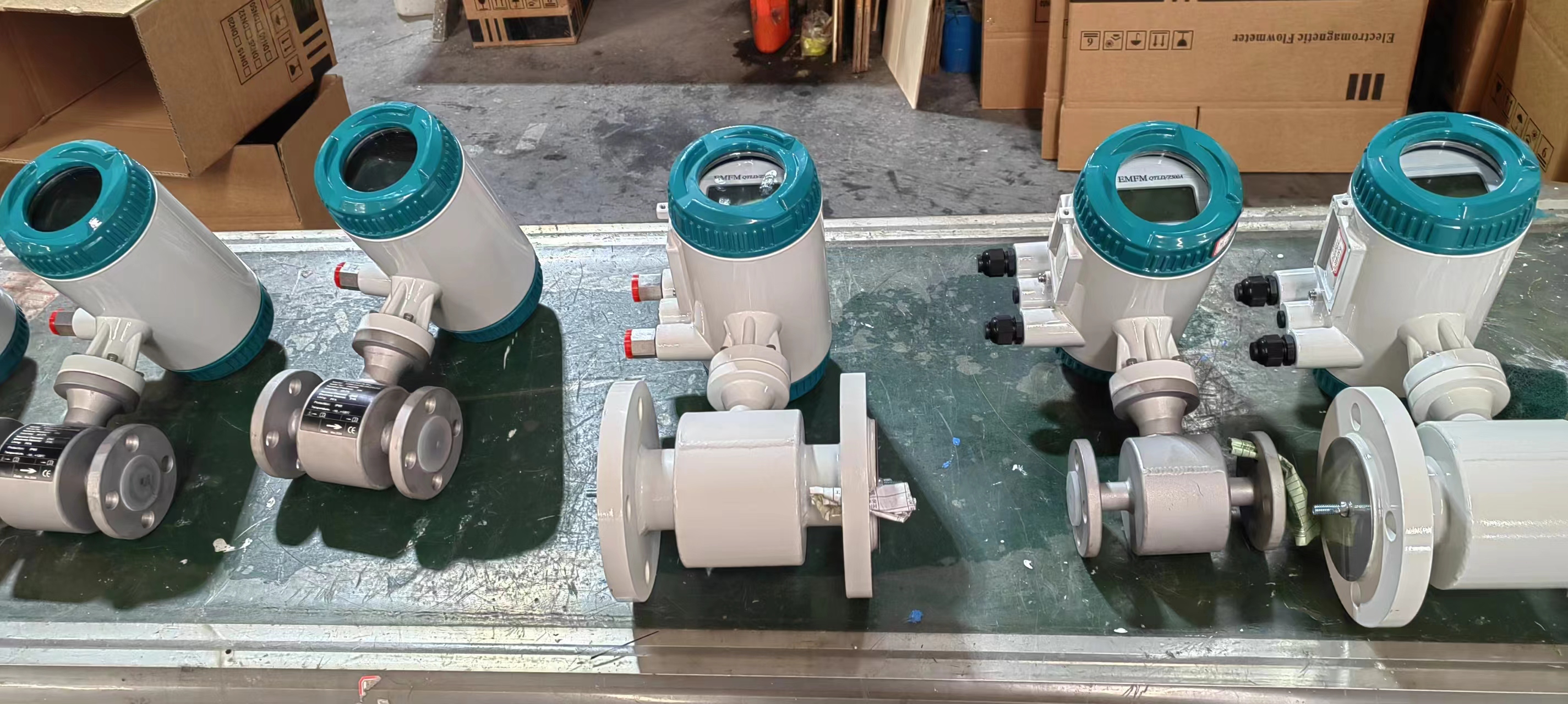

-.jpg)

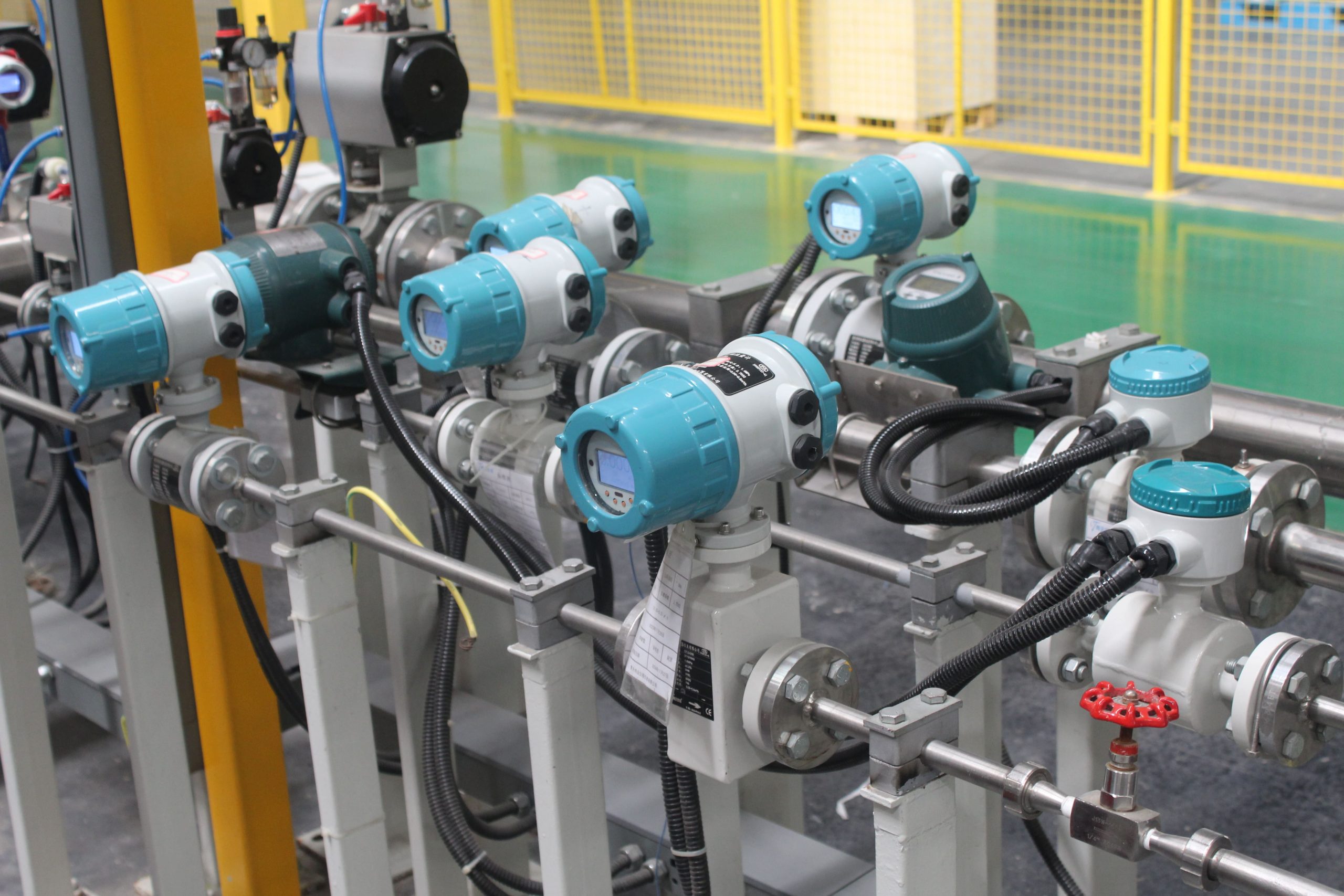

-.jpg)