12VDC Dirty Water Electromagnetic RS485 Flow Meter Hart Communication Magnetic Flowmeter

Selecting the appropriate installation point for an electromagnetic flowmeter is crucial for accurate and reliable measurements. Here are some considerations and guidelines to help you choose the right measuring installation point:

Straight Pipe Length:

Install the electromagnetic flowmeter in a section of straight pipe. The presence of straight pipe sections upstream and downstream of the flowmeter helps to achieve a fully developed flow profile, ensuring accurate measurements. Typically, a minimum of 5 to 10 straight pipe diameters upstream and 3 to 5 diameters downstream is recommended.

Avoid Turbulent Flow:

Choose an installation point where the fluid flow is stable and not turbulent. Turbulence can affect the accuracy of flow measurements. Avoid locations near pumps, valves, elbows, and other flow disturbances.

Avoid Locations with Vibration:

Install the flowmeter in a location free from excessive vibration. Vibrations can impact the stability of the electromagnetic field, leading to measurement inaccuracies. Use vibration isolators if necessary.

Avoid Air Pockets:

Ensure that the flowmeter is installed in a location where air pockets or bubbles are minimized. Air in the fluid can affect the conductivity and disrupt electromagnetic measurements.

Proper Orientation:

Install the flowmeter in the correct orientation, as specified by the manufacturer. The flow direction arrow on the flowmeter should align with the actual flow direction in the pipe.

Avoid Extreme Temperatures:

Choose a location where the ambient temperature is within the specified operating range of the flowmeter. Extreme temperatures can affect the performance of the flowmeter and its electronic components.

Accessibility for Maintenance:

Ensure that the installation point provides easy access for maintenance and calibration activities. Consider the location’s accessibility for routine checks, sensor cleaning, and any necessary repairs.

Pipe Material and Diameter:

Verify that the pipe material is compatible with the electromagnetic flowmeter. Additionally, confirm that the pipe diameter is within the range specified by the flowmeter manufacturer for optimal performance.

Electromagnetic Compatibility (EMC):

Consider electromagnetic compatibility in the installation environment. Avoid locations with strong electromagnetic interference, as it can affect the accuracy of the flowmeter. Adequate grounding is crucial to minimize interference.

Distance from Source of Electromagnetic Interference:

Install the flowmeter at a sufficient distance from potential sources of electromagnetic interference, such as high-voltage equipment or heavy machinery, to prevent disturbances in the measurement signal.

Proper Grounding:

Ensure proper grounding of the flowmeter to minimize electrical noise and interference. Follow the manufacturer’s guidelines for grounding.

Avoid Excessive Bends:

Minimize the number of bends in the pipe near the flowmeter. Excessive bends can create turbulence and affect the flow profile.

Consider Pipe Material and Linings:

Take into account the material of the pipe and any lining, as it can affect the magnetic properties of the fluid and impact the flowmeter’s performance.

Before finalizing the installation point, consult the manufacturer’s documentation for specific guidelines and recommendations related to your electromagnetic flowmeter model. Following these considerations will help ensure accurate and reliable measurements over the long term.

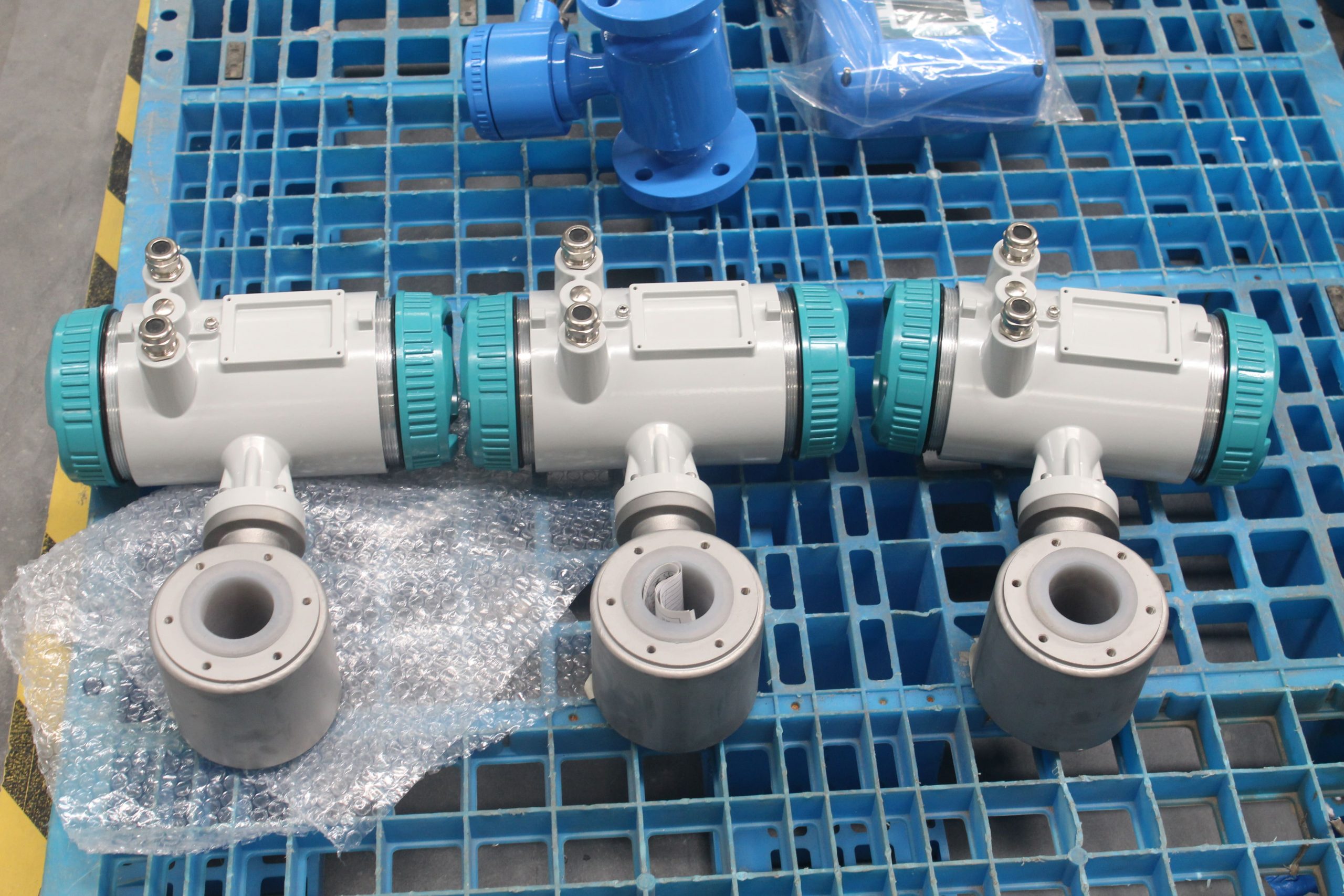

-.jpg)

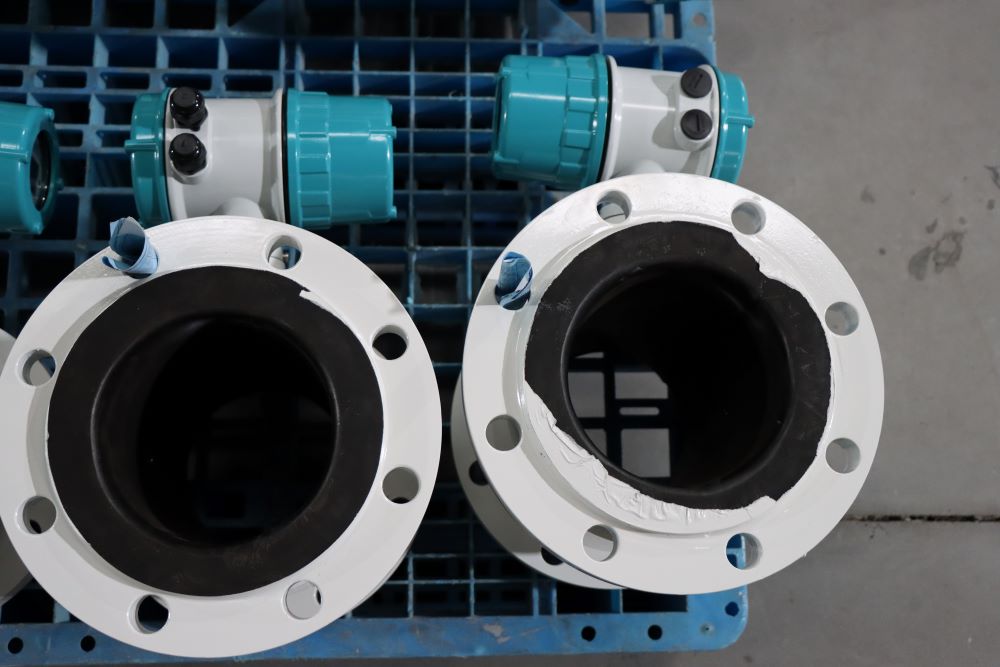

-.jpg)

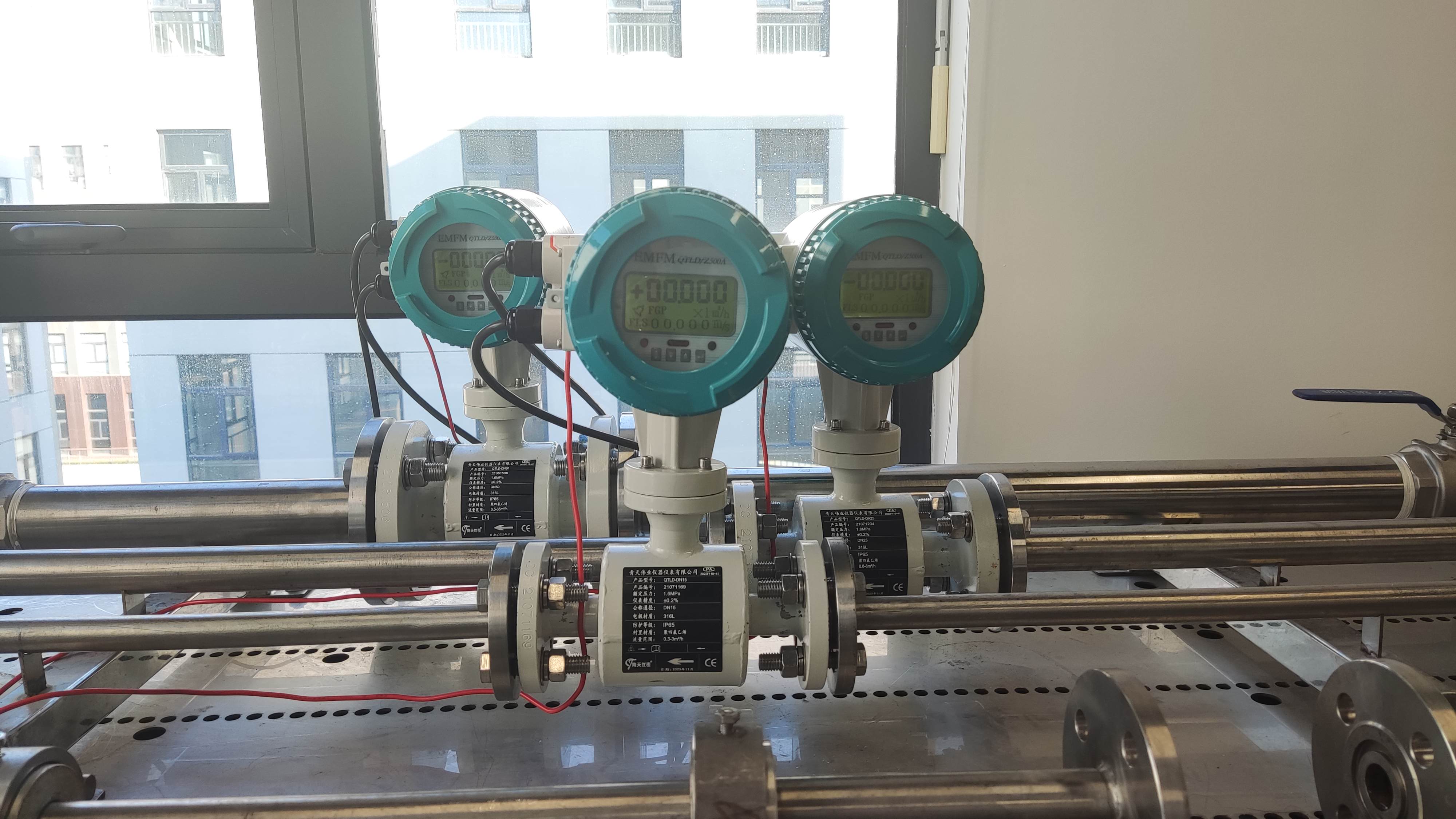

-.jpg)

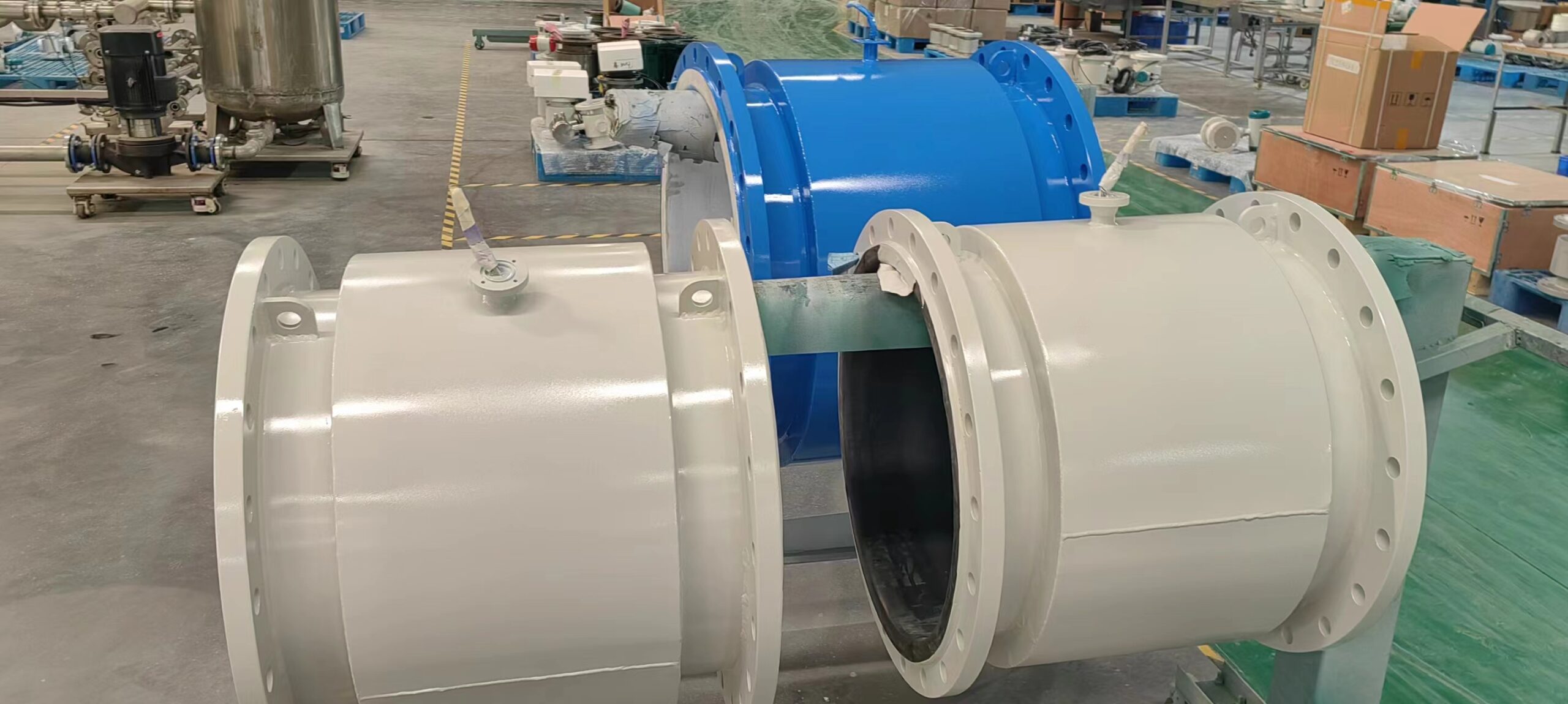

-.jpg)