0.1% Accuracy Professional Cheap Coriolis Mass Flow Meter for Cryogenic Liquids Mass Flowmeter

Proper installation of Coriolis mass flowmeters is crucial for ensuring accurate and reliable measurement. Here are some key installation points to consider:

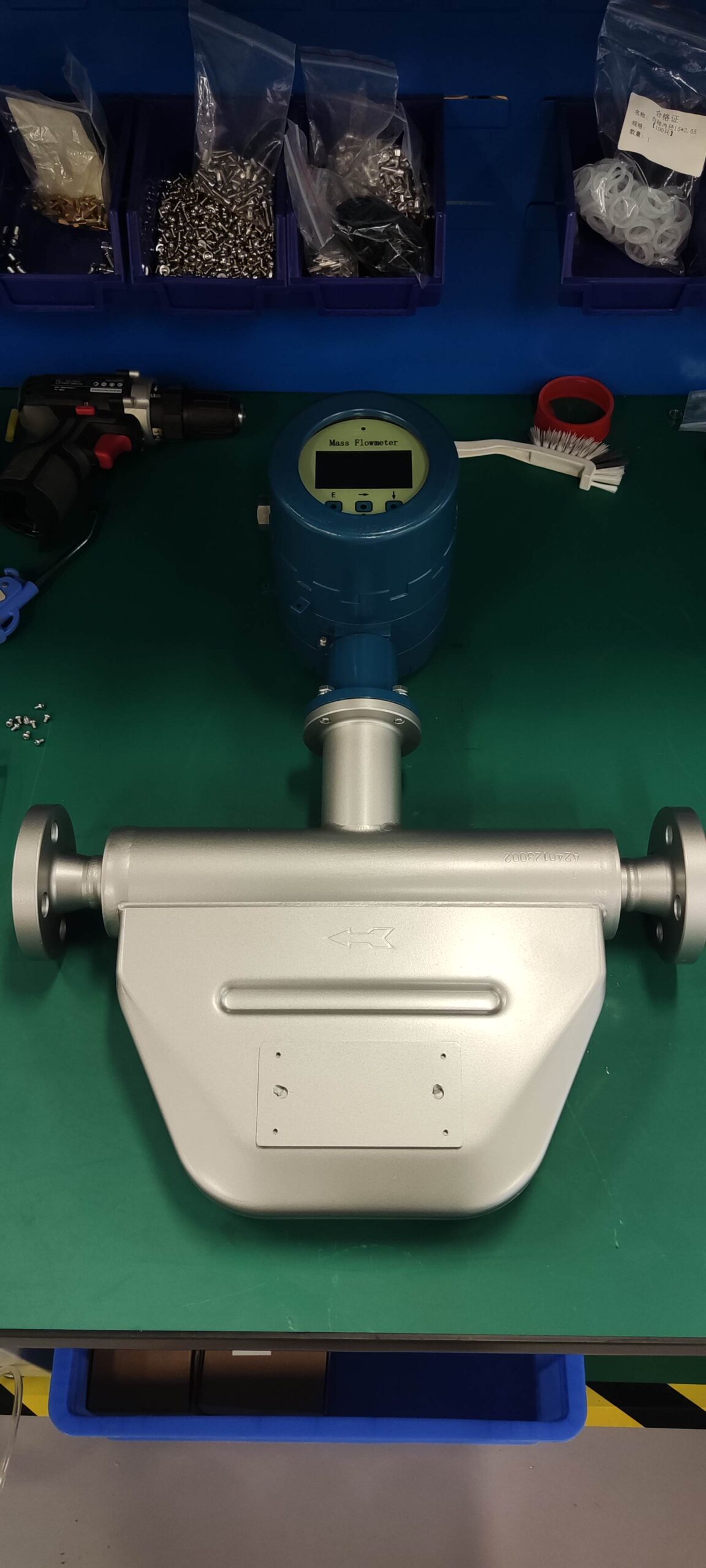

Orientation: Coriolis flowmeters can typically be installed in any orientation (horizontal, vertical, or inclined), but it’s essential to follow the manufacturer’s guidelines for optimal performance. Ensure that the flowmeter is mounted securely and aligned correctly with the flow direction.

Straight Run Requirements: Provide sufficient straight pipe runs upstream and downstream of the flowmeter to minimize flow disturbances and ensure stable flow conditions. The required lengths of straight pipe may vary depending on factors such as pipe diameter, flow velocity, and the presence of elbows, valves, or other flow disturbances. Consult the manufacturer’s recommendations for specific requirements.

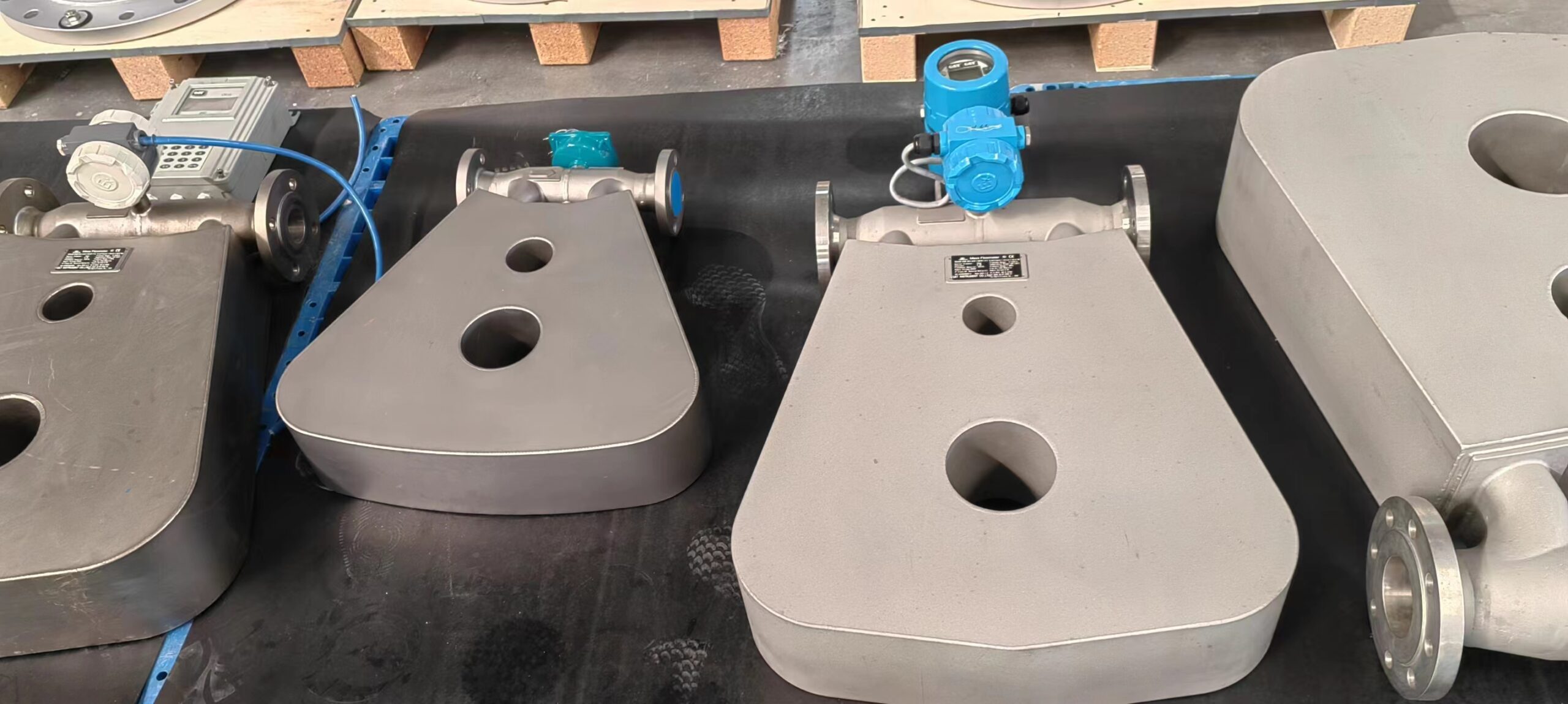

Mounting Location: Install the flowmeter in a location that allows easy access for installation, maintenance, and calibration. Consider factors such as accessibility, ambient temperature, vibration, and exposure to corrosive or hazardous environments when selecting the mounting location.

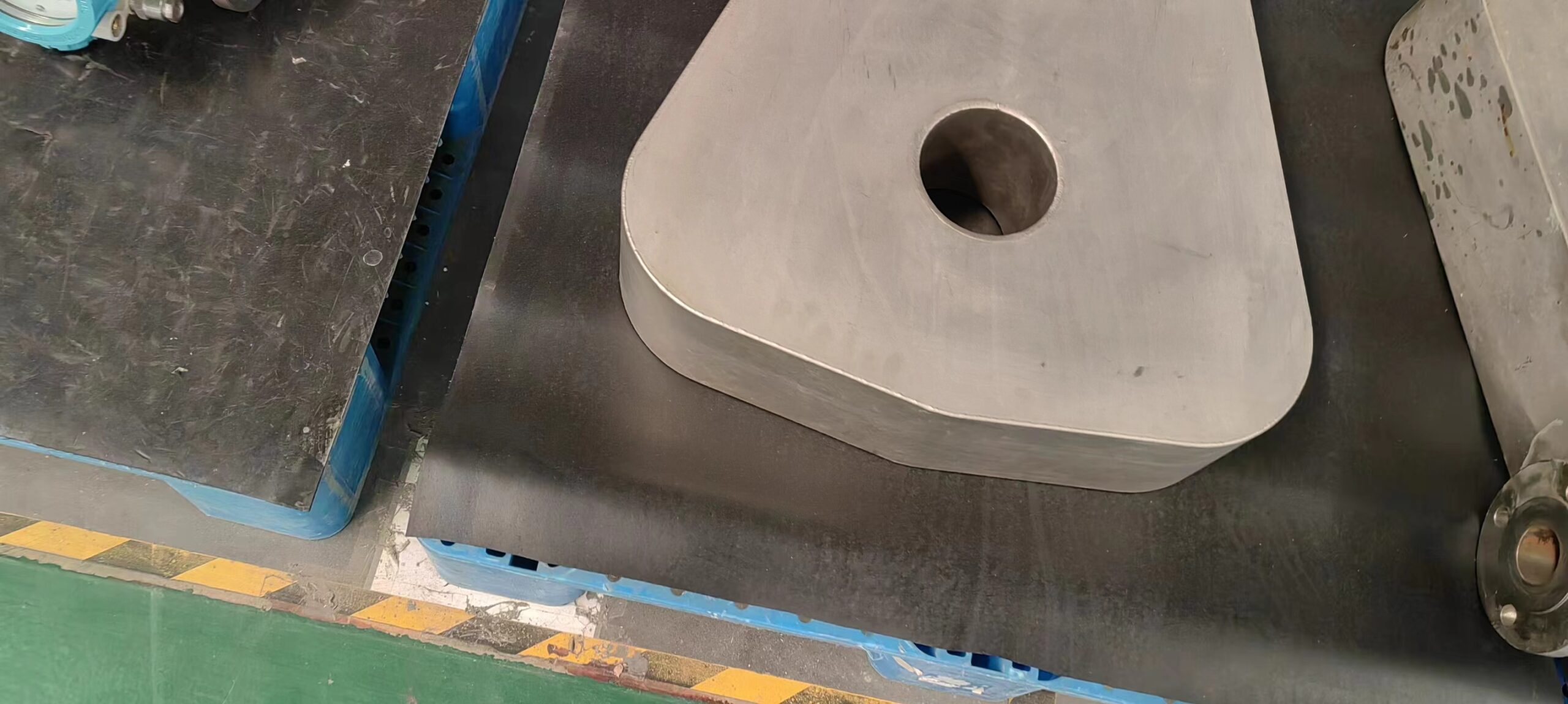

Support and Bracing: Ensure that the flowmeter is adequately supported and braced to prevent excessive vibration or movement, which can affect measurement accuracy. Use appropriate mounting hardware and follow the manufacturer’s recommendations for support requirements.

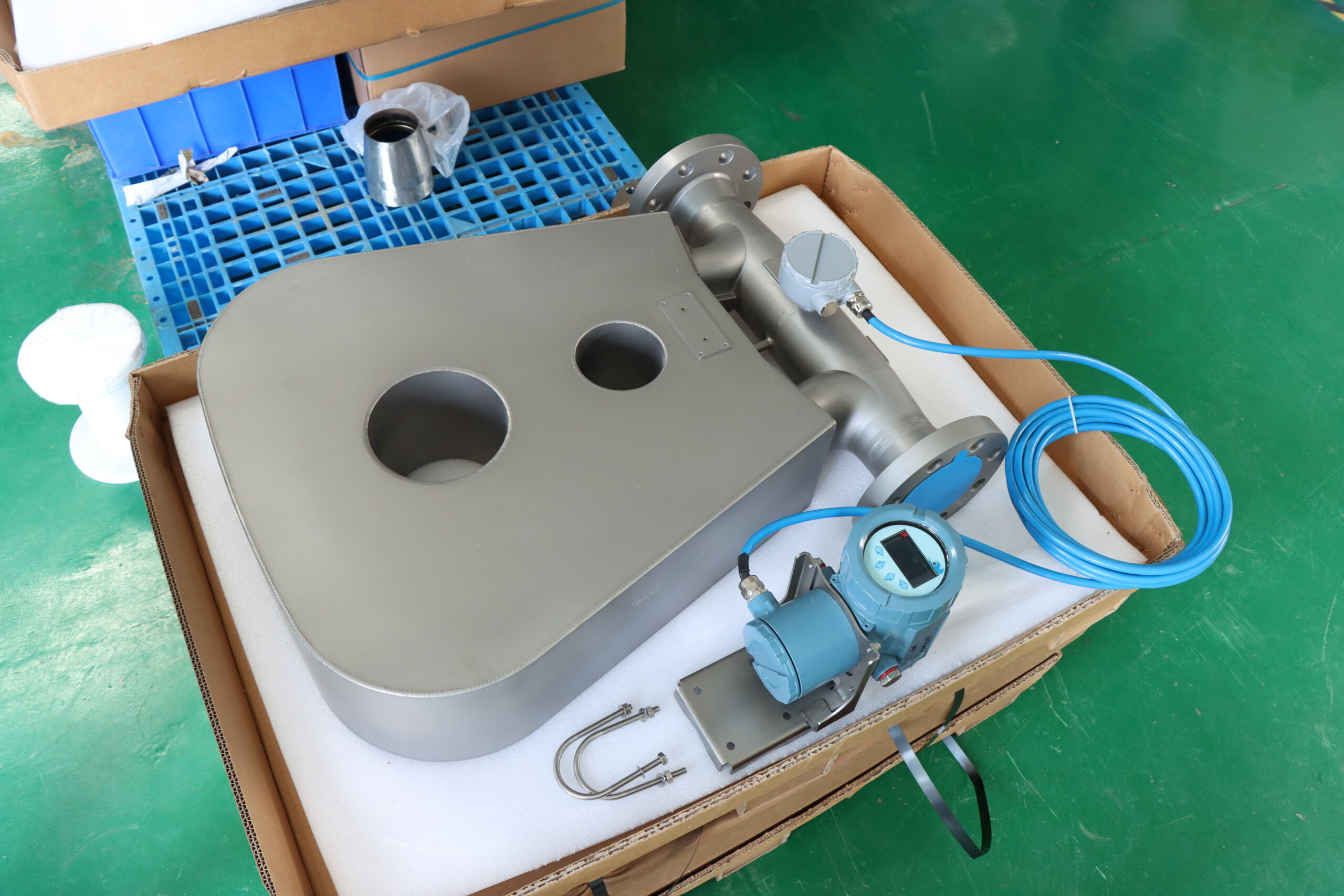

Electrical and Instrumentation: Provide suitable electrical connections and grounding for the flowmeter according to the manufacturer’s specifications. Install any required instrumentation, such as temperature and pressure sensors, in the designated locations and ensure proper integration with the flowmeter.

Calibration: Perform initial calibration and verification of the flowmeter according to the manufacturer’s instructions before putting it into service. Regular calibration checks may be necessary to maintain measurement accuracy over time.

Environmental Considerations: Consider environmental factors such as temperature, humidity, and exposure to sunlight when selecting the installation location. Install protective enclosures or shielding if the flowmeter is exposed to harsh or corrosive environments.

Piping Configuration: Install the flowmeter in a piping configuration that minimizes the risk of air or gas pockets, which can affect measurement accuracy. Avoid sharp bends, elbows, or sudden changes in pipe diameter that may cause turbulence or flow disturbances.

Sealing and Leakage Prevention: Ensure proper sealing and leak prevention measures are in place to prevent fluid leakage and maintain process integrity. Use appropriate gaskets, seals, and fittings suitable for the fluid and operating conditions.

Safety Precautions: Follow all safety guidelines and regulations applicable to the installation and operation of Coriolis mass flowmeters, especially in hazardous or classified areas. Adhere to industry standards and best practices to minimize the risk of accidents or incidents.

By paying attention to these installation points and following the manufacturer’s recommendations and industry best practices, you can ensure the proper installation and reliable performance of Coriolis mass flowmeters in your application.