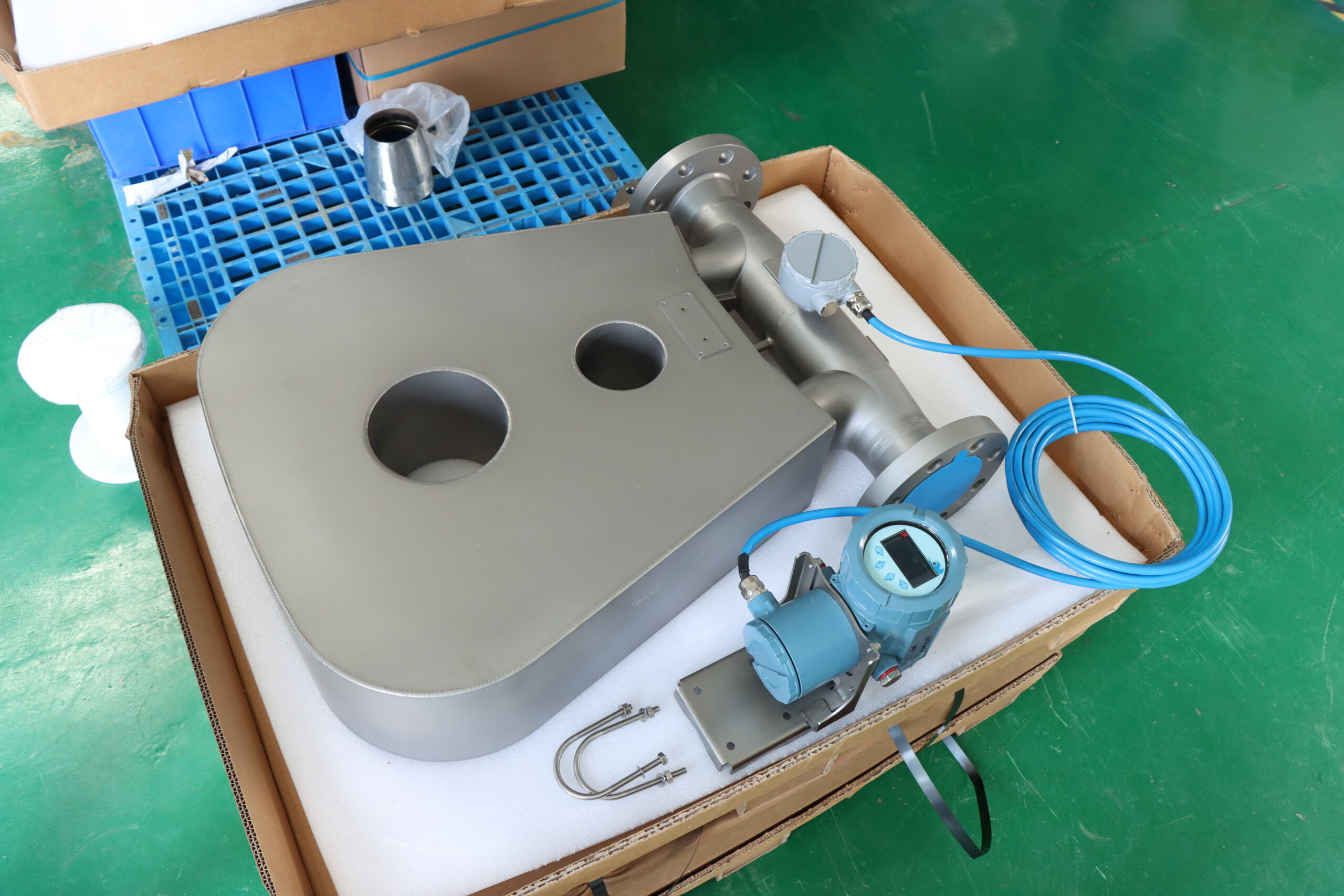

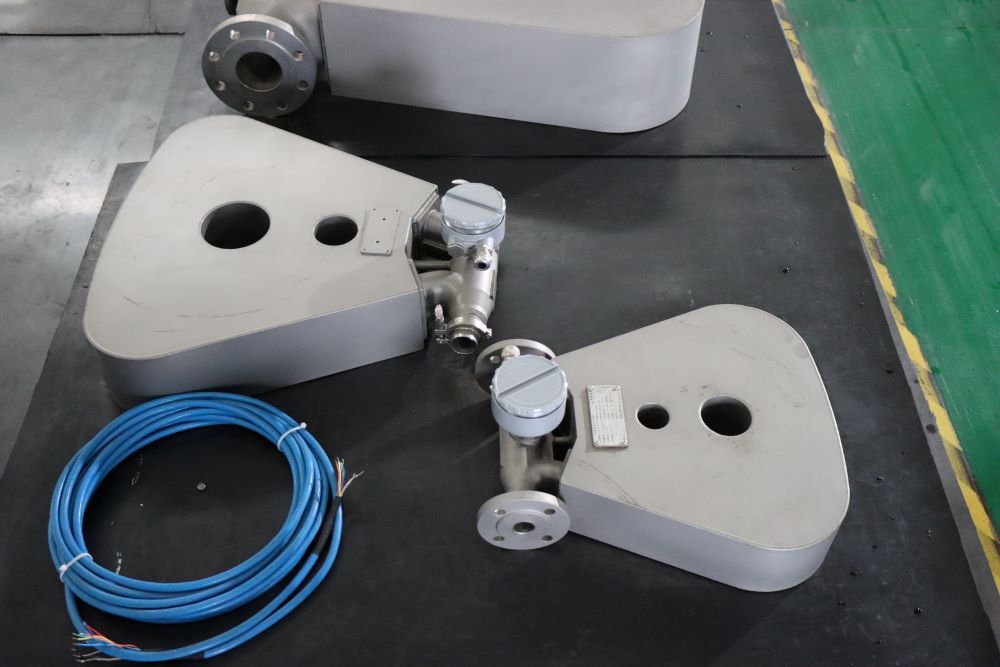

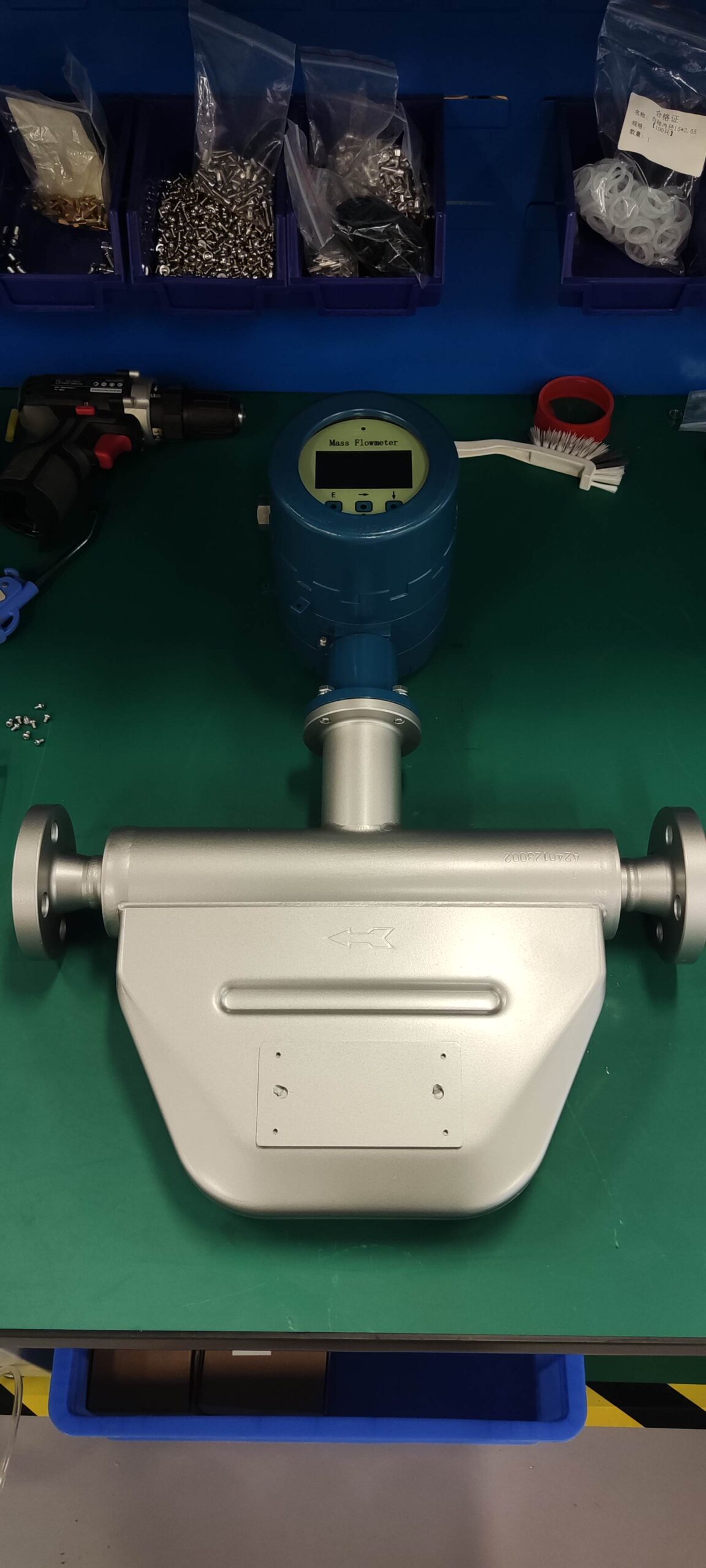

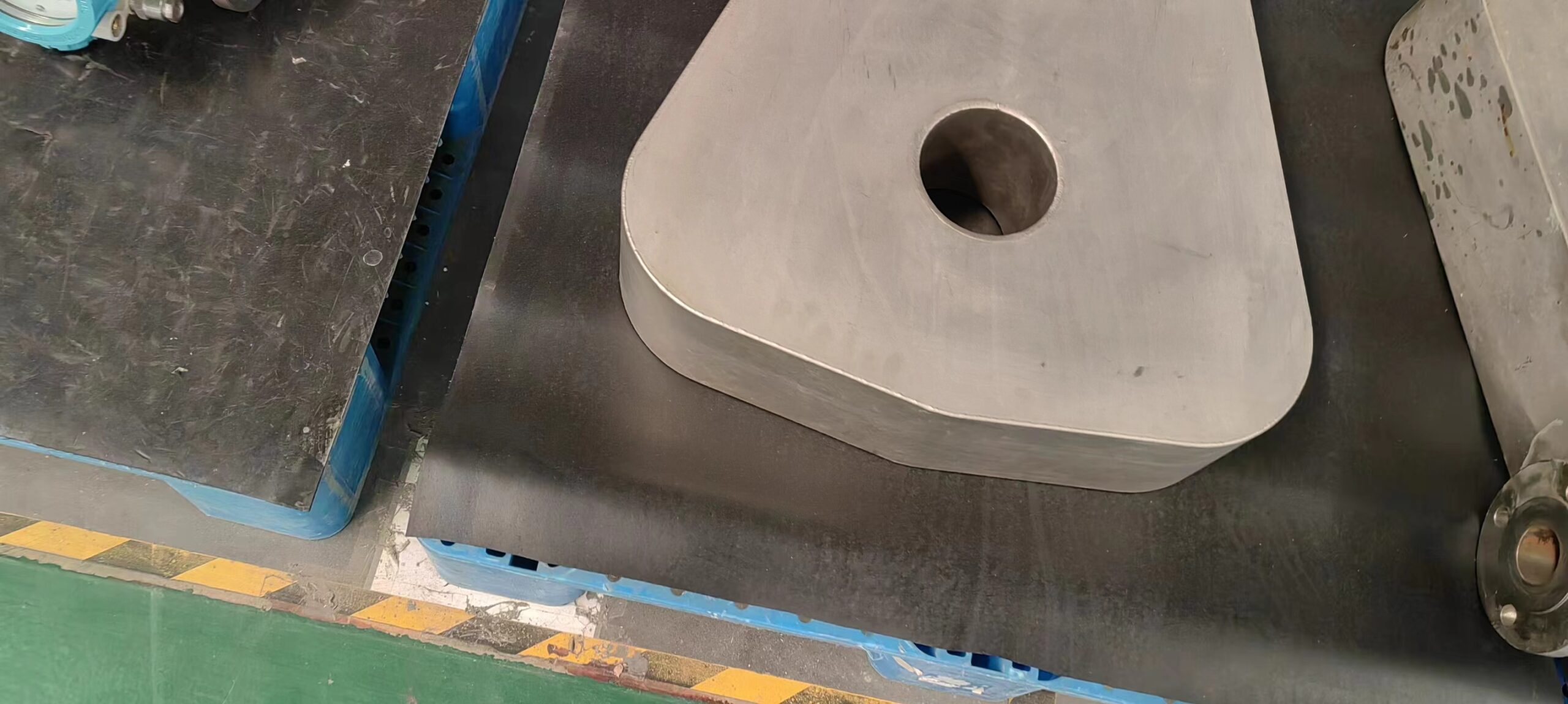

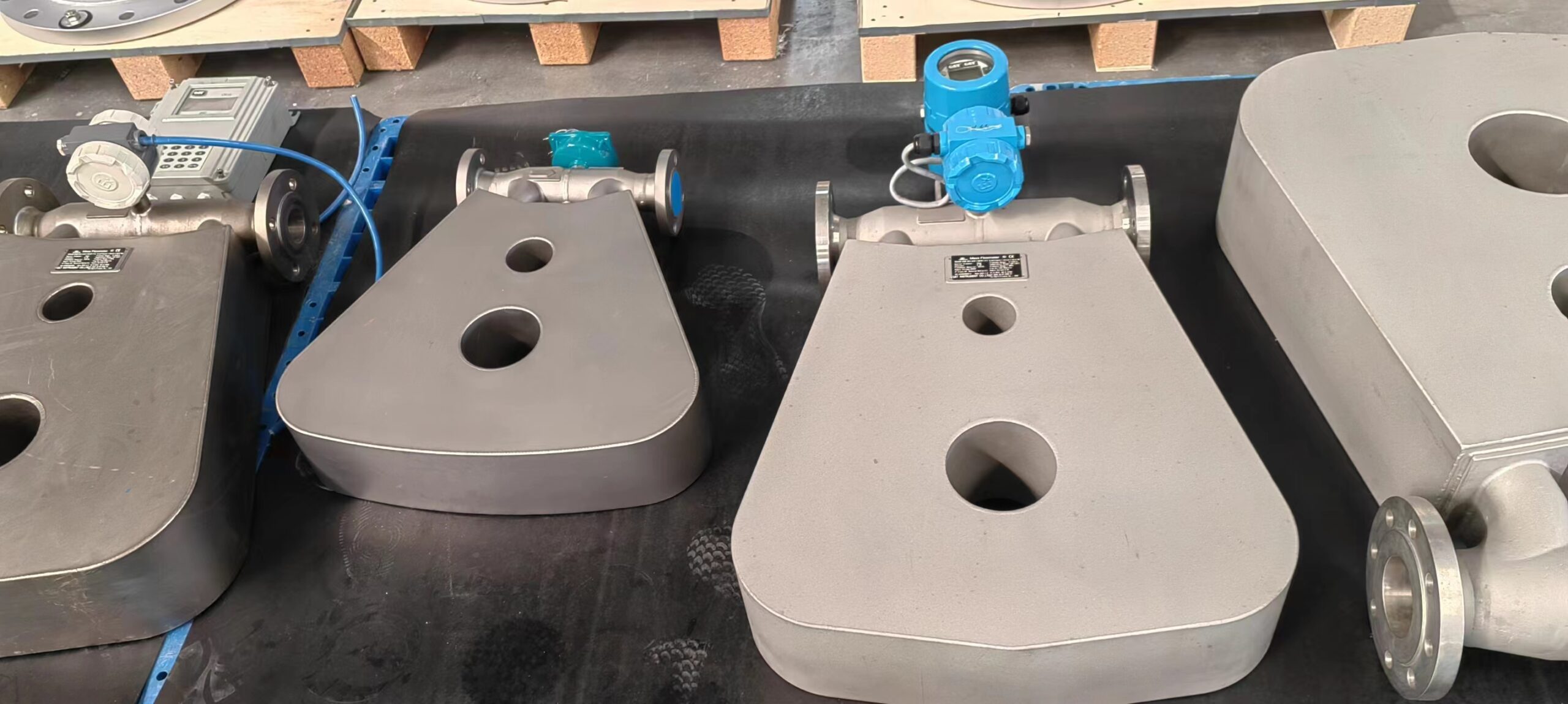

0.1% Accuracy Coriolss Mass Flow Meter Crude Oil Mass Flow Meter

Selecting the right Coriolis mass flowmeter involves considering several factors to ensure it meets the requirements of your application. Here are some key steps to follow when selecting a Coriolis mass flowmeter:

Understand Application Requirements: Begin by understanding the specific requirements of your application, including the type of fluid to be measured (liquid, gas, or multiphase), flow rate range, temperature and pressure conditions, viscosity, density variations, and any other relevant parameters.

Flow Rate Range: Determine the expected flow rate range for your application. Coriolis mass flowmeters come in various sizes and can measure flow rates ranging from very low to very high flow rates. Select a flowmeter with a measurement range that encompasses your expected flow rates.

Fluid Properties: Consider the properties of the fluid to be measured, such as viscosity, density, temperature, and conductivity. Ensure that the selected flowmeter is compatible with the fluid properties and can provide accurate measurements under varying fluid conditions.

Pipe Size and Connection Type: Choose a flowmeter with the appropriate pipe size and connection type for your application. Consider the size of the piping system where the flowmeter will be installed and select a flowmeter that fits seamlessly into the existing infrastructure.

Accuracy and Precision: Evaluate the accuracy and precision requirements of your application. Coriolis mass flowmeters typically offer high accuracy and repeatability, but the level of accuracy may vary depending on the specific model and manufacturer. Choose a flowmeter that meets your accuracy requirements.

Operating Conditions: Consider the operating conditions of your application, including temperature, pressure, and environmental conditions. Ensure that the selected flowmeter is designed to operate reliably under the specified conditions and is resistant to factors such as vibration, corrosion, and harsh chemicals.

Additional Features: Consider any additional features or capabilities that may be beneficial for your application, such as digital communication protocols (e.g., Modbus, HART, Profibus), diagnostic functions, self-calibration capabilities, and integration with control systems.

Cost and Budget: Evaluate the cost of the flowmeter and ensure it fits within your budget constraints. Consider the total cost of ownership, including installation, maintenance, and calibration expenses, over the lifetime of the flowmeter.

Manufacturer Reputation and Support: Choose a reputable manufacturer with a track record of providing high-quality flowmeters and reliable customer support. Research customer reviews, testimonials, and industry certifications to assess the manufacturer’s reputation.

Consult with Experts: If you’re unsure about which flowmeter is best suited for your application, consult with flow measurement experts, engineers, or manufacturers’ representatives. They can provide valuable insights and recommendations based on their expertise and experience.

By following these steps and thoroughly evaluating your application requirements, you can select the most suitable Coriolis mass flowmeter for your specific needs, ensuring accurate and reliable flow measurement in your industrial processes.